As a leading manufacturer of FRP composites, Strongwell adheres to hundreds of engineering standards. ASTM D790 is among the most utilized specifications in the plastics industry.

In this article, Strongwell’s Director of Research and Development, Bhyrav Mutnuri, will share more about this standard and why it’s important for engineers and designers regarding project design.

What is ASTM D790?

ASTM D790 (Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials) is a standard testing approach for identifying the flexural characteristics of FRP composites.

With this standard, Strongwell can identify the flexural strength and flexural modulus (also known as the modulus of elasticity), which are crucial for withstanding bending loads and deflection. These two characteristics help designers when selecting the most appropriate material for their use case.

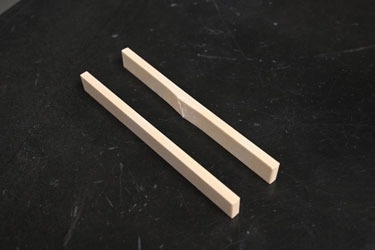

Image Credit: Strongwell Corporation

How is this Test Conducted?

In this testing approach, a small sample of the material is cut and evaluated in a bending setup, where it acts as a simple beam supported at two points and loaded at the center. Throughout the test, the applied load and resulting deflection at the midpoint are recorded and used to calculate both the flexural strength and flexural modulus.

Image Credit: Strongwell Corporation

Why is it Important for Pultrusion Manufacturers to Carry Out this Test?

"This test method is used to evaluate both unreinforced and reinforced plastics, including high-modulus composites and electrical insulating materials. The flexural characteristics are particularly helpful for quality control and specification purposes.

While various composites and plastics may seem similar, this test assesses some of the performance properties important for engineers when designing structures.

Bhyrav Mutnuri (Director of Research and Development) took on the role of Product Development Engineer at Strongwell in 2018. He now takes care of the lab’s daily operations, monitors all research and development efforts, and works closely with potential and existing clients to market new tailored products through pultrusion.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.