By Muhammad OsamaReviewed by Lexie CornerMay 6 2025

By Muhammad OsamaReviewed by Lexie CornerMay 6 2025A new study published in Advanced Materials Interfaces presents an innovative method for repurposing post-consumer thermoplastic waste into cost-effective, high-performance energy harvesters.

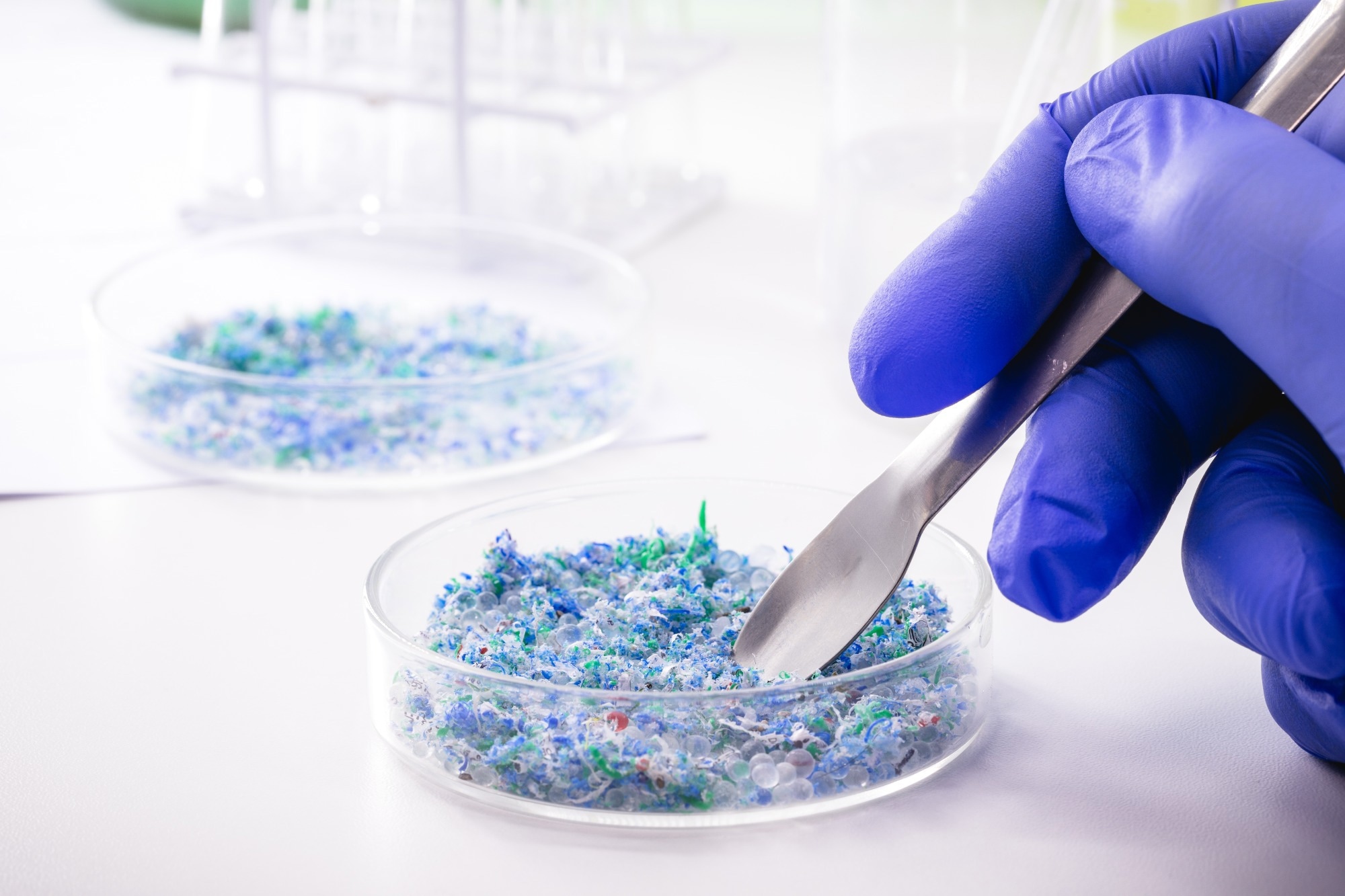

Image Credit: RHJPhtotos/Shutterstock.com

By combining plastic waste with polyvinylidene fluoride (PVDF), researchers found that the natural immiscibility of waste plastics, typically a barrier to recycling, could actually enhance mechano-electric energy conversion.

The goal: tackle plastic waste while generating sustainable energy using materials as common as food packaging.

Advancements in Energy Harvesting Technologies

PVDF is widely recognized for its strong piezoelectric and triboelectric properties, which make it ideal for converting mechanical energy into electricity. Its lightweight, flexible, and chemically stable nature also makes it ideal for nanogenerators.

The β-phase of PVDF exhibits superior piezoelectric performance, which can be enhanced by incorporating fillers, like carbon-based materials (graphene and carbon nanotubes). These improvements have enabled PVDF-based nanogenerators to power small electronic devices and sensors.

Incorporating waste-derived materials into PVDF systems offers a dual benefit: reducing plastic pollution while improving energy conversion efficiency. However, the high cost of advanced materials and fillers remains a significant barrier to large-scale adoption.

Introducing a Novel Sustainable Energy-Harvesting Approach

The researchers developed a sustainable and cost-effective approach to energy harvesting by incorporating immiscible thermoplastic waste, sourced from post-consumer products like food packaging, into PVDF-based systems. This strategy not only tackles environmental concerns but also reduces reliance on high-cost, conventional materials.

To fabricate the energy-harvesting materials, PVDF fiber membranes were produced via electrospinning, using PVDF powder dissolved in dimethylformamide. These membranes were then combined with molten blends of widely used thermoplastics - including high-density polyethylene (HDPE), polypropylene (PP), polystyrene (PS), and polyethylene terephthalate (PET) - to form immiscible composites that maintained the unique characteristics of each polymer.

The resulting composite materials were integrated into triboelectric nanogenerators (TENGs), where the PVDF membranes and plastic waste blends functioned as triboelectric pairs. The experimental setup featured copper electrodes and polymethyl methacrylate (PMMA) plates equipped with movable springs to increase mechanical interaction and energy conversion efficiency.

To evaluate electrical performance, the team measured output voltage, current, and charge density using digital storage oscilloscopes, charge sensors, dielectric impedance analyzers, and profilometers. Structural and thermal properties were further analyzed through techniques like scanning electron microscopy (SEM), differential scanning calorimetry (DSC), and Fourier-transform infrared (FTIR) spectroscopy.

Key Findings: Impact of the Waste-Integrated Approach

The results demonstrated the strong potential of repurposing plastic waste for energy harvesting applications.

A nanogenerator composed of PVDF and a specific blend of thermoplastic waste (60 wt% PET and 40 wt% PS-HDPE-PP) achieved an outstanding open-circuit voltage of 800 V, a short-circuit current of 260 µA/cm2, and a charge density of 710 nC/m2. These values significantly surpassed those of traditional PVDF-nanoparticle composites.

The device maintained consistent mechanical-to-electrical energy conversion across repeated cycles, confirming both reproducibility and operational stability. The enhanced output was largely attributed to triboelectric effects driven by the distinct surface interactions between PVDF and the blended waste polymers. Key factors contributing to the improved performance included surface roughness, polymer composition, and charge affinity.

Further insights from FTIR spectroscopy revealed notable molecular interactions within the composite material, reinforcing the importance of waste blend composition in optimizing energy output. Overall, integrating immiscible plastic waste into PVDF-based systems not only improved energy harvesting efficiency but also offered a sustainable, scalable solution for managing plastic waste within the context of advanced energy technologies.

Download your PDF copy now!

Real-World Potential and Sustainability Impact

This research highlights a promising path forward for sustainable energy technologies. By developing low-cost nanogenerators from everyday plastic waste, the study addresses two major global challenges: the need for clean, decentralized power sources and the urgency of reducing plastic pollution.

These PVDF-based devices are especially well-suited for applications in wearable electronics, biomedical sensors, smart textiles, and wireless monitoring - anywhere lightweight, self-powered systems are needed. Their ability to convert everyday mechanical energy into electricity opens the door for use in both urban and remote environments.

Beyond their technical performance, these devices embody circular economy principles by turning waste into a functional resource. Integrating piezoelectric and triboelectric mechanisms into a single platform further extends their design versatility.

Future work will focus on optimizing material compositions and refining fabrication techniques. Long-term durability testing and scale-up studies will also be key to moving from laboratory prototypes to commercial products.

Journal Reference

Slobodian, P., & et al. Turning Plastic Waste Immiscibility into an Advantage: Efficiency Improvement of PVDF-Based Energy Harvesters Using Post-Consumer Thermoplastics. Advanced Materials Interfaces, 2500070 (2025). DOI: 10.1002/admi.202500070, https://advanced.onlinelibrary.wiley.com/doi/10.1002/admi.202500070

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.