Chinese system integrator EKSOFT is using ABB’s Stressometer® systems to equip its customers with high performance flatness and measurement control solutions for silicon steel production.

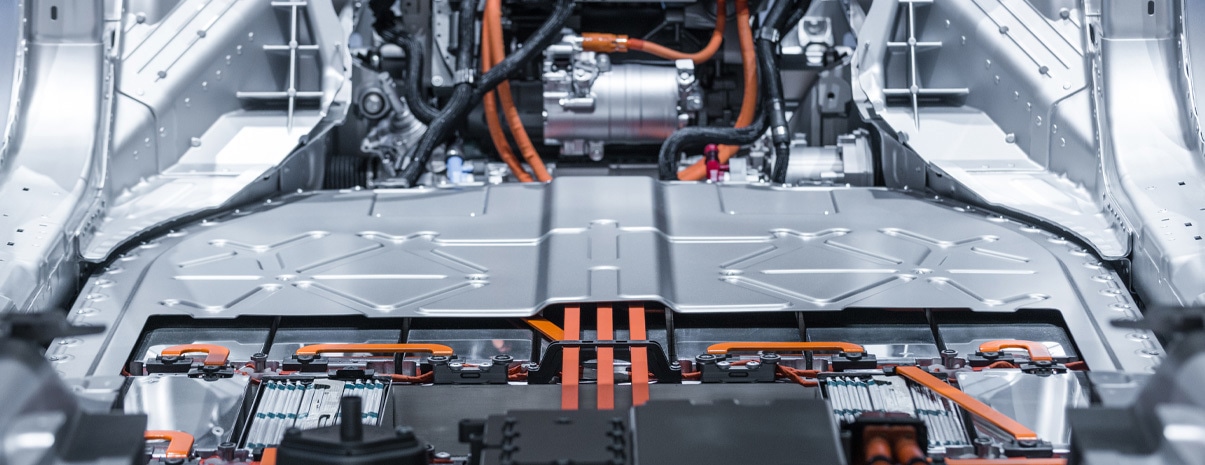

From power generation and distribution to EVs and home appliances, silicon steel is a key ingredient in the electrification of society. Enabling smaller and more efficient components with lower energy losses, it can be found in a wide range of consumer and industrial equipment and plays a core role in the transition to electrical vehicles (EVs).

In China, the country’s focus on prioritizing EV battery production and electrification infrastructure is seeing the demand for high-quality silicon steel increasing faster than other steel types. With a dual focus on both growing its exports and servicing the electrification of its own society, it has been rapidly growing its silicon steel production industry, with output estimated to reach 18 to 20 million tons by 20261.

Image Credit: ABB Inc.

To support the country’s rapidly expanding silicon steel industry, ABB has strengthened its collaboration with EKSOFT, a key electrical system integrator. Based in Beijing, EKSOFT integrates ABB’s advanced Stressometer flatness measurement and control systems into its solutions for high quality silicon steel production. These solutions offer precise control in challenging cold rolling mill environments, helping manufacturers satisfy the increasing demands from electrical equipment producers for silicon steel to help drive the electrification revolution.

With its magnetic properties, silicon steel is an essential ingredient in the production of motors, generators, and transformers, but has unique physical properties that make it difficult to process. The brittle nature of silicon steel, combined with its high temperatures and mechanical stress during rolling, can increase the risk of cracks and surface imperfections that can impact on its quality, as well as strip breaks that can disrupt production.

“With the improvements delivered by our Stressometer solutions, our customers can optimize production quality, reduce costs, and meet the high performance standards required by the electrification industry.”

Accuracy makes the difference

Image Credit: ABB Inc.

For silicon steel producers, the solution is to use equipment that can provide accurate measurement and control throughout the rolling process to minimize scrap, reduce rework, and improve product quality.

Over the past two years, a total of eight ABB Stressometer systems have been supplied by EKSOFT to silicon steel manufacturers, including five new orders in 2024.

With three systems currently being commissioned, ABB’s Stressometers will play a key role in China’s ambitious electrification efforts and its drive to lead global EV production and battery manufacturing.

Employing around 50 people, EKSOFT is a rapidly growing system integrator that specializes in control systems for rolling mills. Since 2022, it has partnered with ABB to deliver advanced flatness solutions for silicon steel production applications. By including the Stressometer systems in its offerings, EKSOFT enables its customers to operate their cold rolling processes with tighter tolerances, boosting productivity, increasing yield, and minimizing costly rework and material waste.

A major benefit of the Stressometer systems is their ability to withstand challenging environments, with only minimal maintenance needed throughout their operational life. This results in the lowest lifecycle costs and reduces the need for spare parts, enabling users to achieve long-term savings. By improving production efficiency and reducing waste, they also deliver on ABB’s commitment to sustainability in resource-intensive industries, with significant potential savings in energy through reduced reworking.

Expanding opportunities in China’s electrification sector

With a global market share of 66 percent in flatness measurement and control systems, ABB is committed to its ongoing relationship with EKSOFT to support China’s rapidly growing silicon steel industry. By combining ABB’s advanced flatness measurement technologies with EKSOFT’s expertise in rolling mill control systems, the collaboration enables both companies to capitalize on the high demand for silicon steel in industrial, commercial, and consumer electrification applications.

“Together with EKSOFT, we are bringing ABB’s proven flatness control technology to China’s leading silicon steel producers,” said ChenYang Yu from ABB's Measurement & Analytics division. “With the improvements delivered by our Stressometer solutions, we are enabling them to optimize production quality, reduce costs, and ultimately meet the high performance standards required by the electrification industry, particularly in EV manufacturing.”

“We have been working with ABB Stressometer systems for some time, and we are impressed by the high quality ABB brings to the table,” said Mr. Liu Wenchao, president of EKSOFT.

“These advanced systems are perfect for China’s rapidly growing silicon steel industry which is committed to improving production efficiency and reducing waste.”