A new CoNi-based superalloy shows exceptional strength and ductility in 3D printing, and could lead to high-temperature parts with fewer defects.

Image Credit: Quality Stock Arts/Shutterstock.com

Image Credit: Quality Stock Arts/Shutterstock.com

In a recent Materials & Design publication, researchers introduced a novel high entropy CoNi-based superalloy, referred to as CoNi-HESA, engineered for superior performance under high-temperature conditions and designed for laser powder bed fusion (L-PBF), a key additive manufacturing (AM) process.

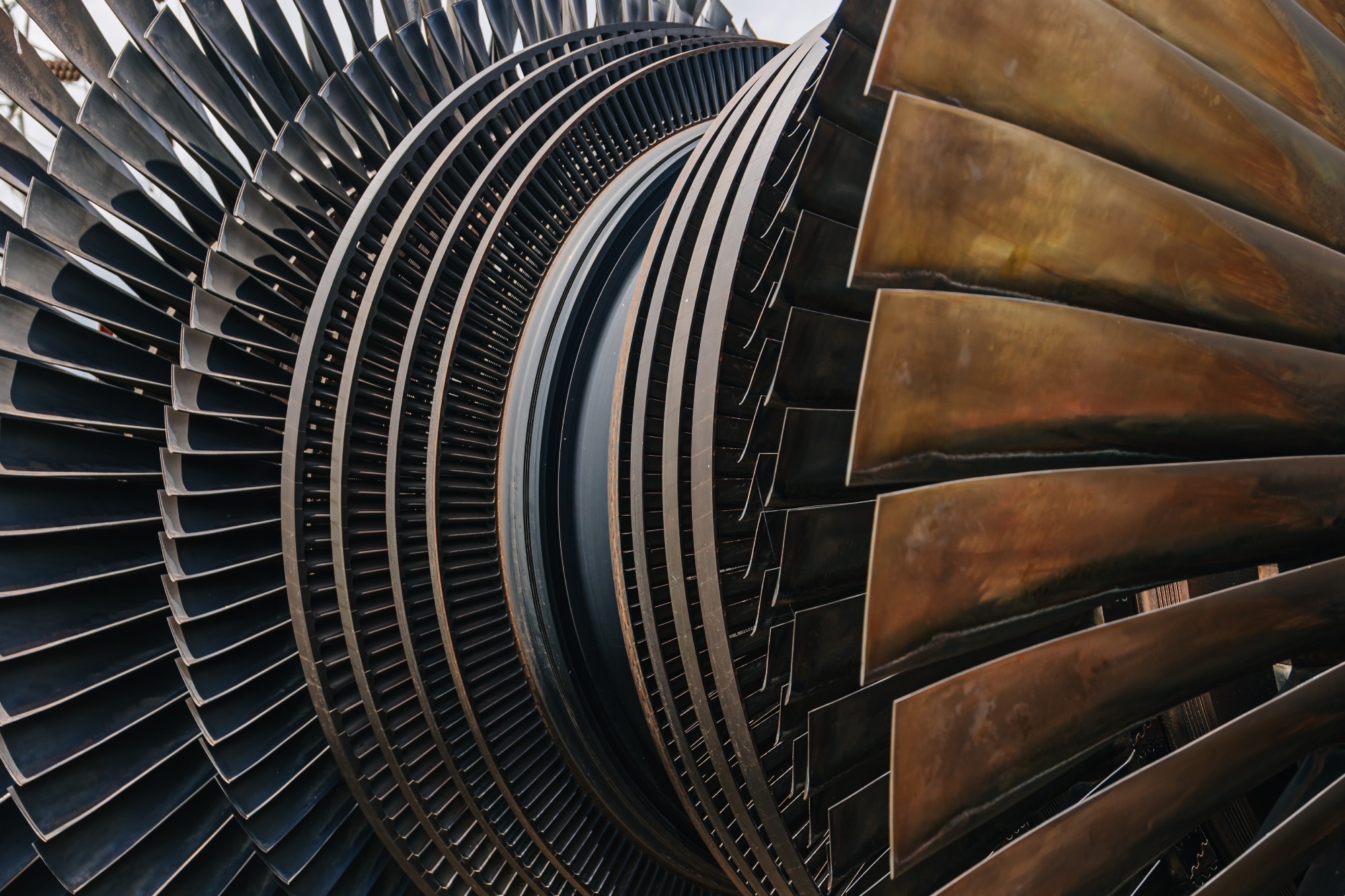

The alloy combines multiple elements to achieve high strength, ductility, and resistance to common 3D printing defects, such as porosity and cracking. Designed for use in manufacturing aerospace and energy components (such as wind turbines), it targets environments where traditional nickel-based superalloys often face weldability and fabrication limitations.

Why High Entropy Alloys?

Conventional nickel-based superalloys, especially those strengthened by gamma prime (γ′) precipitates, have long been the go-to for turbine blades and other high-temperature parts. However, their performance is constrained by processability issues during additive manufacturing.

High-entropy alloys (HEAs), which feature several principal elements in near-equiatomic ratios, can have improved mechanical properties, thermal stability, as well as corrosion resistance. CoNi-based variants are particularly attractive due to their high melting points, favorable phase stability, and ability to support significant γ′ fractions. Still, integrating them into AM processes is challenging.

Strategic Alloy Composition

The CoNi-HESA alloy was developed using thermodynamic modeling to ensure system stability and manufacturability. It features near-equal atomic ratios of cobalt and nickel, alongside additions of chromium, aluminum, vanadium, titanium, tantalum, and tungsten. These elements combine to form a stable face-centered cubic (FCC) matrix with a high volume of γ′ precipitates, both important in high-temperature strength and long-term phase stability.

The alloy powder was produced through argon gas atomization, yielding spherical particles sized between 20 and 63 µm, ideal for additive manufacturing. Scanning electron microscopy (SEM), electron backscatter diffraction (EBSD), and compositional analyses confirmed the good powder morphology and microstructural consistency, though minor micro-segregation was seen in characterization.

Additive Manufacturing Process

Using a Renishaw AM400 system, the team optimized L-PBF parameters through response surface methodology, varying laser power (110-190 W) and scan speed (550-850 mm/s). Their goal was to maximize part density while minimizing cracking and porosity.

Optical microscopy and SEM were used to analyze melt pool morphology, dendritic structures, and porosity levels. Mechanical testing, including tensile and compression tests, was conducted at room and elevated temperatures to evaluate the alloy’s performance in as-built conditions.

Strong Results

The CoNi-HESA alloy achieved relative densities above 99 %, with excellent microstructural integrity. The as-printed parts exhibited a cellular/dendritic structure with stable FCC phases and well-dispersed γ′ precipitates, especially in interdendritic regions.

High configurational entropy was key to slowing phase transformations and atomic diffusion, effectively reducing defect formation. The alloy delivered tensile strengths exceeding one gigapascal and ductility above 30 % at room temperature. Even at 900 °C, it maintained strong performance, confirming its potential for long-term service in high-temperature environments.

One of the most significant results was the alloy’s ability to suppress the formation of topologically close-packed (TCP) phases, which commonly degrade mechanical performance in conventional superalloys. This was attributed to both the carefully tailored composition and the influence of entropy on phase stability.

The optimized process windows, identified through response surface methodology, showed clear correlations between processing parameters, microstructure, and mechanical performance, reinforcing the importance of integrating alloy design with AM process control.

Download your PDF now!

Outlook for High-Performance AM Alloys

This study marks a significant advancement in the design of high-entropy superalloys for additive manufacturing. By combining thermodynamic modeling with precise process optimization, the researchers successfully produced dense, reduced-defect components suitable for extreme environments.

With its high mechanical strength and excellent microstructural properties across a wide temperature range, CoNi-HESA has strong potential for application in the aerospace and energy industries that require reliable, high-performance AM parts.

Journal Reference

De Nardi A., Mohammadzadeh A., et al. (2025). Laser powder bed fusion of a novel CoNi-based high entropy superalloy. Materials & Design, 259, 114741. DOI: 10.1016/j.matdes.2025.114741, https://www.sciencedirect.com/science/article/pii/S026412752501161X