Viscosity the most important physical property of a lubricating oil, as determines how easily the oil circulates and its load carrying capability. Maintaining the correct balance between low viscosity for ease of circulation and high viscosity for load carrying is important for the application of any type of lubricant.

Oil provides other benefits in addition to lubrication, so it is important that it is able to flow under any condition. During use, the oil viscosity is influenced by contaminants such as water, oxidation, fuel entering the oil, and soot. This makes viscosity measurement an important test for the oil used in a mechanical system.

Kinematic viscosity (the resistance to flow under gravity) is the conventional method to monitor machine condition.

The following parameters influence the viscosity of oil:

- Water contamination: Free water and oil don't mix chemically. However, under certain circumstances they combine to form an emulsion that looks similar to coffee with cream. This emulsion will actually increase the kinematic viscosity of the oil

- Additives: Additives can be part of the oil formulation. For instance, the formulation of multigrade mineral-based engine oils, excluding naturally high VI base oils, includes a springy additive that is compact at low temperatures and expands at high temperatures due to increasing fluid solvency

- Soot: Soot is a common issue in diesel engines. It is a particle that results in a colloidal suspension in the oil. The oil's dispersant additive is designed to prevent agglomeration and growth of soot particles facilitates the formation of a colloidal suspension

- Temperature variations: The Viscosity Index (VI) of a lubricating oil is the extent to which the viscosity of the oil changes with temperature. A low VI indicates a comparatively large change in the viscosity due to temperature change, while a high VI denotes that the oil undergoes a very little change in viscosity. Oil with a viscosity that does not change much between the temperatures of 40°C and 100°C has a higher VI than an oil with a relatively higher change in viscosity. The Viscosity Index Test (ASTM D 2270) is based on the kinematic viscosity of the oil at 40°C and 100°C, or 104°F and 212°F. Generally, a VI greater 95 is considered high. Oils with a high VI offer greater protection to critical components across a broad range of temperatures

- Thermal and oxidative degradation by-products: These by-products are insoluble, but the oil carries them in a stable suspension

Kinematic viscosity, ν, indicates the flow behavior of a substance under the influence of Earth’s gravity. It is calculated by dividing the dynamic viscosity by density (ρ), which is defined as mass per volume.

Kinematic viscosity is widely established due to historical reasons:

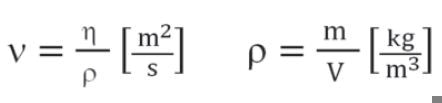

Gravity is constant anywhere on Earth and as a driving force, it does not need any elaborate technical equipment. The SI unit is either mm2/s or m2/s, where 1 m2/s = 1,000,000 mm2/s. The SI units can be derived from the kinematic viscosity equation:

The other common units used are centistokes (cSt) or stokes (St), where 1 St = 100 cSt

Measuring Kinematic Viscosity

Gravimetric Capillary

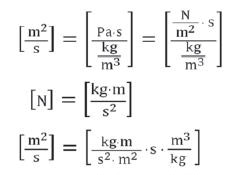

The most common method for measuring kinematic viscosity is the use of a gravimetric capillary (Figure 1) that is usually temperature controlled at 40°C and 100°C for multigrade oils, and only 40°C for single grade oils. Generally, measurements made using capillary viscometers rely on the relation between time and viscosity.

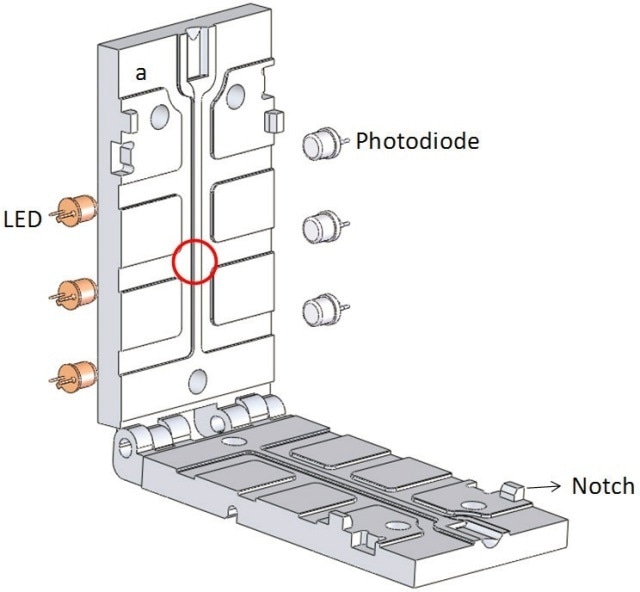

The more viscous an oil, then the longer it takes to flow via a capillary under the influence of gravity alone. Currently, there are several standardized capillaries in use. Most the laboratory instruments use glass capillaries or “tubes”. A more recent development for field measure of kinematic viscosity utilizes a split aluminum cell capillary (Figure 2).

Figure 1. Glass capillary types. 1. Ostwald (direct) 2. Ubbelohde (direct) 3. Cannon-Fenske (direct) 4. Houillon (Modified Zeitfuchs crossarm) reverse flow

These instruments are designed to work either as direct-flow capillaries or as reverse-flow capillaries. For the direct-flow capillaries, the sample reservoir is positioned below the measuring marks. For the reverse-flow capillaries, it is located above the marks. Opaque liquids can be tested using the reverse-flow capillaries, and some can have a third measuring mark. Having three measuring marks provides two subsequent flow times and improves the measurement repeatability.

Figure 2. Split aluminum cell capillary

Common Types of Kinematic Viscometer

Manual Constant Temperature Bath Systems

In these systems, the direct-flow capillaries are immersed in a highly accurate temperature controlled bath. A sample of oil, usually 10 ml, is suctioned into the tube until it reaches the start point. Then, the suction is released to make the oil flow by gravity through the controlled capillary section of the tube.

Two or three marks are visible on the tube. An operator observes the oil meniscus as it passes the start point and then measures the time taken for the oil to pass the final mark. The tubes are chosen so that the test takes at least 200 seconds to complete, making it easier for manual timekeeping. ASTM D 445 is the technique for kinematic viscosity and was initially written for the manual method.

Figure 3. Cannon Instrument Company constant temperature bath

The advantages and disadvantages of the manual constant temperature bath systems are listed below:

Advantages

- Easy tube replacement

- Inexpensive

- Accurate

Disadvantages

- Opaque/dark oils require additional steps

- At least 10 ml of oil required

- Manual cleaning is required for tubes

- Slow operation and requires operator to monitor time manually (typically 10 samples per hour)

Automated Modified Ubbelohde Method

An automated modified Ubbelohde method is a common system used by laboratories. Here, a 10 ml bottle is placed in a small carousel rack. Like the manual method, the system draws oil up to the tubes. However in this method, a computer program controls all of the tasks, removing the requirement for an operator to monitor and time the oil flow.

Figure 4. Automated Ubbelohde viscometer

The advantages and disadvantages of the automated modified Ubbelohde method are as follows:

Advantages

- Dual solvent option for difficult to clean sooty oil samples

- Automation carousel for sample loading

- Automation – self-cleaning and drying tubes and sample vials

Disadvantages

- Sample volume is 5 ml per measurement (minimum)

- Slow – 12 samples per hour (10 position carousel)

- Less flexibility as two tubes fixed in place

- High solvent usage during self cleaning (15 ml per sample)

Direct Flow Capillaries

These systems are highly favored for in-service condition monitoring, as they are more appropriate for opaque fluids. The lab versions exhibit higher throughput and flexibility. “Houillon” or “Hele-Shaw” are the common names for this method, and the ASTM that describes it is ASTM D7279.

A common question posed by someone who is considering buying a viscometer is how does this method compare to ASTM D445, which is a widely acknowledged viscosity method. As ASTM D7279 exhibits exceptional repeatability, all that is needed to acquire results similar to ASTM D445 is a standard offset.

For users who focus on changing trends, laboratory instruments designed using this method have exceptional accuracy and surpass machine condition monitoring needs.

Figure 5. Spectro Scientific SpectroVisc Q300 kinematic temperature bath viscometer

To make the measurement using this method, a small oil sample (between 0.6 - 1.6 ml) is pipetted and directly introduced into the tube, which is heated to the desired temperature. To reduce cross contamination, disposable pipette tips are employed.

The following are the advantages and disadvantages of the direct flow capillaries:

Advantages

- High throughput – 25 to 45 samples per hour

- Low sample volume (0.6 ml)

- Semi automation – Self-cleaning and drying tubes and sample vials

- 4 tubes per bath – easy replacement of tubes, requiring below one minute to swap without bath draining

- Dual measurement options (sample measured twice on same tube) for high accuracy new oil blending QC

- Dual solvent option for hard to clean sooty oil samples

Disadvantages

- Houillon capillaries susceptible to stuck particles

- Automated sample loading is not standard

- High solvent usage during self-cleaning (15 ml per sample)

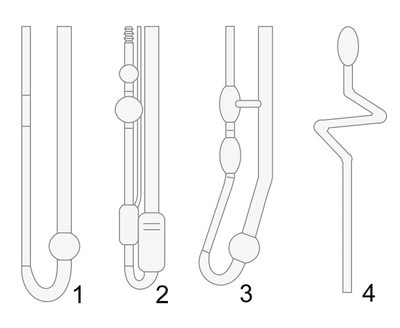

Portable, Solvent Free Direct Flow Capillary Viscometer

When a kinematic viscosity result is required for field or mobile applications, a new generation of viscometers based on the Hele-Shaw split cell capillary design can be employed. A single heated aluminum block with a machined capillary ensures temperature controlled viscosity at 40°C without the need to use solvents for cleaning.

As with lab systems, a 60 µl sample is pipetted and introduced into a temperature controlled cell, which is usually set at 40°C. Once the process is finished, the device directly displays the kinematic viscosity on the screen. After the test, the operator vigorously cleans the plates using a cleaning pad, and the cell can be warmed to test the next sample.

The following are the advantages and disadvantages of the portable, solvent free direct flow capillary viscometer:

Advantages

- Low sample volume (0.06 ml)

- Easy to use for an unskilled operator

- Solvent free

- Direct measurement at 40 C

Disadvantages

- Manual cleaning required

- Indirect measurement of viscosity at 100 C with VI supplied

- Plate needs to be conditioned before measurements by prewetting with oil

Conclusion

Viscosity is a critical property of a fluid, and monitoring viscosity is highly essential to oil analysis. Kinematic viscosity measurement techniques for used oils should be investigated, and the differences between the methods should be considered. It is important that the details of viscosity measurements are understood so that accurate lubrication decisions can be made.

While choosing an onsite viscometer, a user should not expect the laboratory’s kinematic viscometer to be in complete agreement with the onsite instrument, especially for field systems. Instead the conditions, the method, and the user environment should be considered.

The user should review whether the solvents are difficult to obtain or maintain, and whether the equipment will be used routinely. It is advisable to baseline the new oil with the same viscometer that is used with the in-service oil.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.