Since it was introduced in the 19th century, food packaging has made great advances focused on improving food protection and quality, health and safety, providing longer shelf life and adhering to more demanding environmental and international standards.

Image Credit: muph/Shutterstock.com

To address these manufacturing requirements, a wide range of new materials and improved processing techniques have been developed to generate sophisticated, thin, multi-layer packaging.

Multi-layer food packaging has routinely been characterized using FT-IR spectroscopy, however, the need to verify the quality of these increasingly thinner and larger number of multi-layer films in development, manufacturing and failure analysis environments has exceeded the resolution limits of FT-IR technology.

The Mirage IR microscope using photothermal IR spectroscopy (PTIR), provides a new level of capability to provide sub-micron IR characterization of thin multilayer film while eliminating or significantly reducing sample preparation and improving data turnaround times.

Mirage IR Microscope

The Mirage™ IR microscope is an innovative new system uniquely providing sub-micron IR spectroscopy and imaging across a wide variety of applications.

Using a proprietary Anasys technique based upon photothermal IR spectroscopy, Mirage breaks the diffraction limit and bridges the gap between conventional IR microspectroscopy and nanoscale IR spectroscopy. The Mirage solves two of the biggest problems facing the field of IR microscopy:

- Achieving sub-micron IR spatial resolution (an improvement of over 10X) without the need for contact-based ATR accessories.

- Measurement of thick samples in reflection mode, providing transmission quality IR spectra that correlate to industry-standard IR databases.

Sub-micron IR Spectroscopy using PTIR

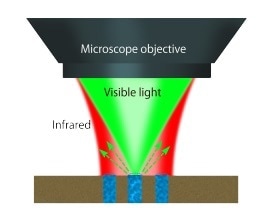

Photothermal IR spectroscopy (PTIR) overcomes the IR diffraction limit by combining a mid-IR pulsed, tunable laser that heats the sample. When the IR laser is at a wavelength that excites a molecular vibration in the sample, absorption occurs, thereby creating photothermal effects.

A visible probe laser, focused to 0.5 μm spot size, measures the photothermal response via the scattered light, as shown in figure 1. The IR pump laser can be tuned through the entire fingerprint region in one second or less, to obtain an IR spectrum.

PTIR is an optical, non-contact based approach, making it fast and easy to use, while maintaining transmission quality spectra. In addition its high quality spectra in reflection mode it enables IR measurement on thick samples and eliminates the need for thin samples in many sample types. This leads to dramatically easier sample preparation, improved ease of use and faster turnaround times.

Due to its unique operating principle, PTIR can be used in both transmission and reflection mode. However, its method of operation is in reflection mode, which eliminates several longstanding limitations for IR microscopy. This provides substantial benefits for the IR community, including minimizing sample preparation and enabling sub-micron spectroscopy.

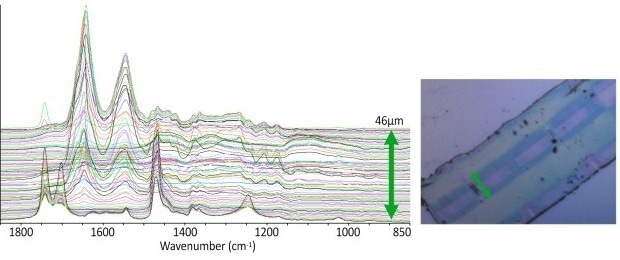

PTIR has consistently shown transmission quality spectra in reflection mode across a wide range of sample types. The sub-micron resolution is demonstrated in figure 2, showing reflection mode spectra on a multi-layer packaging film measured 0.5 μm apart with highly differentiated chemical fingerprints indicating different materials.

Figure 1. A pulsed tunable, IR source is focused on sample. Absorbed IR light causes sample to heat up, creating a photothermal response in the sample. A visible laser probe measures the photothermal response due to IR absorption

Sub-micron Resolution of Multilayer Packaging Film with Mirage

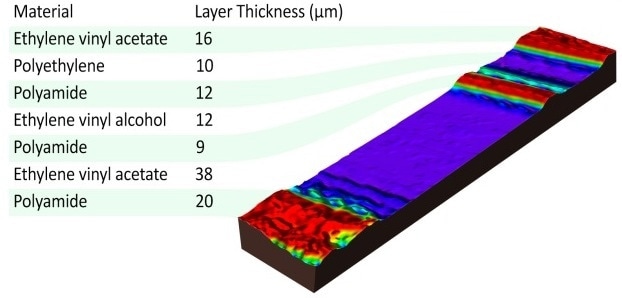

The Mirage IR Microscope performed measurements on a seven-layer packaging film used in the commercial food industry. The following examples highlight the capabilities of Mirage and Photothermal IR spectroscopy. Conventional transmission mid-IR spectroscopy typically cannot be used to measure thick samples because the light is totally absorbed or scattered before it has finished transmitting through the sample. Thus, there is little photon energy reaching the detector. The film layers are shown in figure 2.

Various measurements were performed with Mirage on both thin cross sections and block face samples. All measurements were taken in reflection mode, using a variety of techniques, including point spectroscopy, hyperspectral imaging and single wavelength imaging.

Figure 2. Multi layer packaging film.

Line Array Measurements of Multilayer Films

The data in figure 3 shows a line array of 93 spectra (46 μm length) across the entire cross section of a multilayer polymer film (optical image inset is shown). The data is spaced by 0.5 μm and each spectrum displayed took ten seconds to collect. This data can then be used to easily identify each layer within the film, by comparing to a third party spectral database or internal company IR database. Mirage also allows for the detection of defects within the film by looking for differences between various spectra within a single layer. Sub-micron defects are easily detected and chemically identified within these multilayer films or within polymer blend sample.

Figure 3. Multi layer packaging film – thin section. reflection mode spectroscopy – 93 spectra, 10 sec/spectrum. 10 co-averages/spectra. 0.5 μm spacing, 46 μm line array. Data courtesy of G. Meyers, M. Rickard Dow Chemical Company

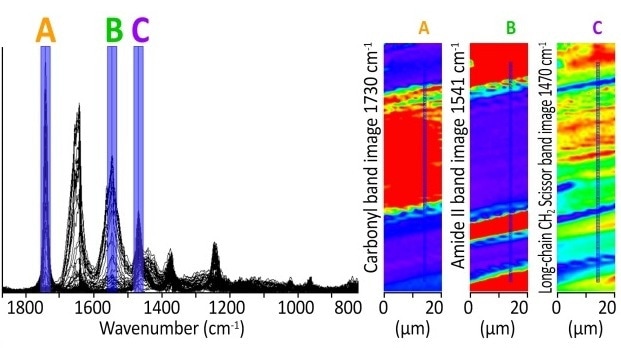

Hyperspectral Imaging of Multilayer Packaging Film

Mirage provides hyperspectral capability to quickly identify the spectra and chemical composition over a wide region. Figure 4 highlights an example of hyperspectral imaging with Mirage. The left image shows a Hyperspectral IR image at 1730 cm-1 of a multilayer film cross section.

The middle image line array spectra from the blue box locations selected within the hyperspectral image. Within the software the wavelength distribution visualized in the hyperspectral image can be changed by selecting different wavenumbers points (denoted by the blue lines) in the spectra.

The right image shows the hyperspectral image at 1545 cm-1, showing the polyamide layers within the multilayer film. This image is displayed by simply by selecting this peak with the blue line in software. The top center hyperspectral image highlights the IR absorbance 1470 cm-1, showing the layers within the multilayer film that contain polyethylene chains.

Figure 4. Packaging sample - block face - multilayer sample – seven layers. Reflection mode - hyperspectral imaging - 1 sec/spectra. 1 scan/spectra. 20 x 85 μm size. 1 μm spacing. Image shows carbonyl band and amide II bands and CH stretching bands

High Speed Point Spectroscopy of Block Face Multilayer Film

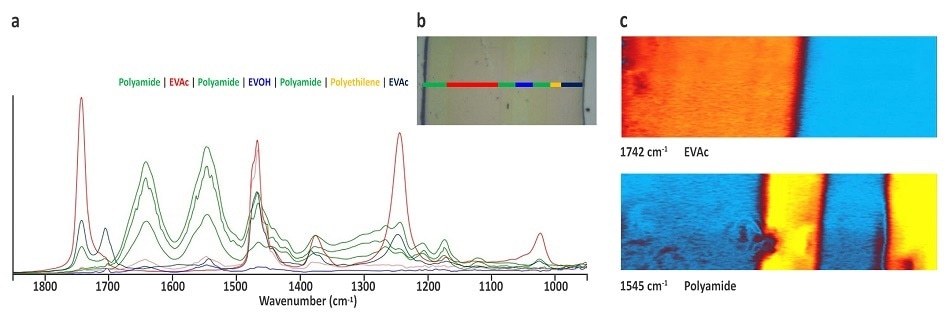

The data in figure 5 shows reflection mode based, line array point spectra across the block face sample of the multilayer polymer film (optical image inset is shown).

The data is spaced manually by the user to identify specific layers. Mirage also uniquely enables high resolution single wavelength imaging to highlight the chemical distribution of specific components in the sample. Here polyamide and EVAc layers are provided in high resolution.

Figure 5. Multilayer packaging film, thin section sample showing (a) Fingerprint section spectra measured using reflection mode spectroscopy – 10 spectra, 100 scan/spectrum total. 140 sec/spectrum. (b) High resolution, single wavelength chemical images with a resolution of 0.5µm showing Polyamide layer at 1545cm-1 and EVAc layer at 1742cm-1. Scan size is 60µm x 20 µm. Chemical Imaging time is about 1min40sec

Conclusion

PTIR eliminates several longstanding limitations for IR microscopy, enabling sub-micron IR spectroscopy and minimizing sample preparation. Mirage addresses numerous sample types with unambiguous chemical characterization, making it a unique technique that provides a huge step forward for the IR spectroscopy community.

Acknowledgments

Anasys Instruments acknowledges Dr. Greg Meyers and Dr. Mark Rickard of Dow Corporation for permission to show the packaging film data.

This information has been sourced, reviewed and adapted from materials provided by Photothermal Spectroscopy Corp.

For more information on this source, please visit Photothermal Spectroscopy Corp.