Published in the Journal of the American Chemical Society, researchers at Linköping University have significantly boosted the efficiency of hydrogen production from water. They achieved this by developing a three-layered material that captures and converts solar energy more effectively than current technologies.

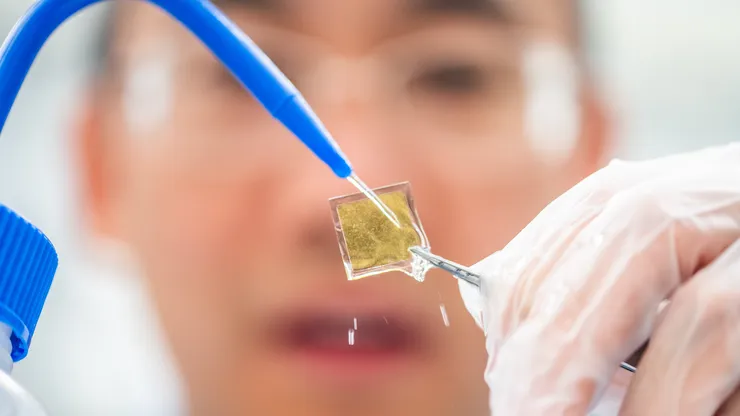

The material can effectively capture sunlight, using the solar energy for hydrogen production through the photochemical water splitting reaction. Image Credit: Olov Planthaber

The material works by capturing sunlight and using that energy to drive the photochemical water-splitting reaction, which separates hydrogen from oxygen. This process is particularly relevant in Europe, as the European Union plans to ban new petrol and diesel cars by 2035.

While electric batteries work well for smaller vehicles, larger modes of transport require alternative clean energy solutions.

Passenger cars can have a battery, but heavy trucks, ships, or aircraft cannot use a battery to store the energy. For these means of transport, we need to find clean and renewable energy sources, and hydrogen is a good candidate.

Jianwu Sun, Associate Professor and Study Lead, Linköping University

The LiU researchers have developed a material that harnesses solar energy to produce hydrogen (H2) from water (H2O) as an alternative to batteries.

Captures the Energy in Sunlight

The research team had previously demonstrated the advantages of cubic silicon carbide (3C-SiC), showing its ability to absorb sunlight and promote the reaction that splits water into hydrogen and oxygen.

Building on this, the team has developed a multi-layered material. It comprises a layer of cobalt oxide, a layer of cubic silicon carbide, and a catalyst that aids in water splitting.

It is a very complicated structure, so our focus in this study has been to understand the function of each layer and how it helps improve the properties of the material. The new material has eight times better performance than pure cubic silicon carbide for splitting water into hydrogen.

Jianwu Sun, Associate Professor and Study Lead, Linköping University

When sunlight hits the multi-layered material, electric charges are generated, which can be used to split water into hydrogen and oxygen.

A significant challenge in developing materials that enable hydrogen production is preventing sunlight's positive and negative electric charges from recombining and neutralizing one another.

In their study, the researchers demonstrate that their material, Ni(OH)2/Co3O4/3C-SiC, with its layer of cubic silicon carbide, is more able to keep charges separate. This improves the efficiency of water splitting.

More Efficient Splitting of Water

Not all hydrogen produced today is "green". Instead, much of the hydrogen available on the market is described as "grey" hydrogen, made from natural gases or fossil fuels. Up to ten tons of carbon dioxide are released to produce one ton of "grey" hydrogen. This has a highly negative environmental effect and contributes to the greenhouse effect.

"Green" hydrogen gas can only be produced via renewable methods, such as with renewable solar electricity.

The LiU researchers' long-term objective is to power the photochemical reaction that creates “green” hydrogen using only solar energy.

The majority of materials currently in development have an efficiency of one to three percent, but 10 % efficiency is the goal if it is to become commercially viable.

Producing “green” hydrogen would become more cost-effective if the reaction were powered solely by solar energy, rather than relying on additional renewable electricity, as is the case with current technology.

Associate Professor and study lead Jianwu Sun says it could take the research team five to ten years to create materials that achieve the desired ten percent threshold.

Journal Reference:

Zeng, H., et al. (2025) Manipulating Electron Structure through Dual-Interface Engineering of 3C-SiC Photoanode for Enhanced Solar Water Splitting. Journal of the American Chemical Society. doi.org/10.1021/jacs.5c04005.