Guangnan Meng, Product Manager for industrial microscopy and metrology at Olympus Americas Inc., talks to AZoM about 3D laser confocal scanning and how the new LEXT OLS5000 system has improved speed, performance, and reliability.

The Olympus LEXT OLS5000 3D laser confocal scanning microscope was launched recently. What has the industry feedback been like?

We have received very positive feedback from customers in various advanced manufacturing industries, including research scientists in nanomaterials engineering, process and failure analysis engineers in semiconductor manufacturing, biomedical engineers in healthcare, and mechanical engineers in additive manufacturing. After seeing the OLS5000 system demonstrations, customers are impressed with its single nanometer measurement capability and accuracy, faster acquisition and analysis speed, easy-to-use software interface and workflow, and the flexibility to fit wide and tall samples. We believe this system has elevated noncontact surface metrology measurements to the next level.

LEXT OLS5000

How has the 4K scanning technology and optics helped improve measurement performance and reliability?

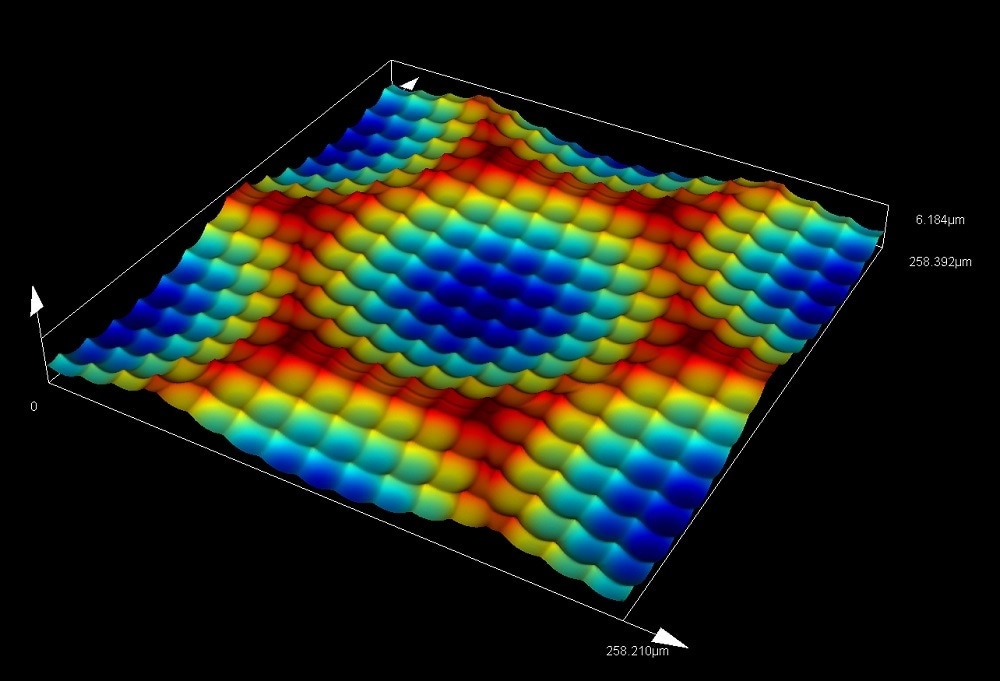

Olympus developed lenses specifically for surface metrology applications. Our dedicated LEXT objectives offer sharp vision to observe very fine topographical details. With new 4K scanning technology, the optical signals are reliably collected by the system with a high signal-to-noise ratio. These technologies help ensure that the OLS5000 microscope accurately measures 3D surfaces with high repeatability.

Is the microscope faster than previous models?

Yes. With completely redesigned hardware and software, the OLS5000 microscope has broken the bottleneck typically associated with laser confocal scanning microscopes, the data acquisition speed. Comparing the OLS5000 to its predecessor, the OLS4100 microscope, the new system is four times faster when data is acquired under the same conditions. The OLS5000 system is currently one of the fastest 3D laser confocal scanning microscopes on the market. In less than twenty seconds, the system can finish scanning a 100-micron vertical depth to collect accurate 3D surface data.

What sample size can be measured?

The OLS5000 microscope accommodates a range of sizes. With five standard frame configurations, the system can fit a sample as wide as 300 mm (12 inches) and as tall as 210 mm (8 inches). It is also possible to mount the microscope to a custom gantry to fit even larger and taller samples.

What lens features does the LEXT microscope have that ensure accurate measurements across the entire field of view?

We use dedicated LEXT objectives to measure surfaces accurately. Not only do these objectives have flat vision within the field of view distortion (minimal spherical aberration), they also are engineered at 405 nm. This means that vertical measurements are very accurate when using the system’s 405 nm laser to detect surface topography.

What applications have benefited the most from the new LEXT OLS5000 microscope?

As industry 4.0 and the internet of things become more common, surface and interface topographies are becoming even more vital for a lot of modern parts to perform correctly. A few examples of surfaces and interfaces that need to be examined include the surface automobile engines to optimize their performance and fuel economy, optical communication devices that rely on the interface to transmit light, and the surfaces of steel to help ensure efficient energy conversion and low signal amplification. Thanks to its minimal sample preparation process, faster data acquisition, and automated data analyzing features, the OLS5000 microscope can accurately measure fine surface topographies in a few minutes. This helps to improve the overall operational productivity and development efficiency of new nano-optic devices and enables companies to check the yield of manufactured parts. Improving productivity is always one of the main goals of any industrial innovation.

Do you have any case studies you’re particularly proud of?

We already have a few application notes on automotive parts and electronics. They are available to view on our website. With more and more systems being delivered to our customers, we believe we will find even more interesting applications for the OLS5000 microscope. Please stay tuned.

What does the future hold for non-contact 3D laser confocal scanning technology?

The future is promising and bright for noncontact 3D surface metrology. Laser confocal scanning microscopy is a reliable, noncontact technology to observe and measure fine surface topographies. With all the evolutionary and revolutionary progress going on in various manufacturing industries, we are expecting more applications for LEXT OLS5000 laser scanning confocal microscopes. We are excited to help change the world together with all these innovators and engineers.

Where can our readers learn more?

Our product webpage is the best resource. It contains technical information, show and tell videos, case studies, and application notes. Of course, nothing beats trying the system out yourself. Please fill out the online contact form, and we will be very happy to arrange a live demonstration.

About Guangnan Meng

Guangnan is a product manager of industrial microscopy and metrology in Olympus Americas Inc. He holds a Ph.D. in physics, and have years of experience in materials science, applied physics, analytical instruments and semiconductor industries.

This information has been sourced, reviewed and adapted from materials provided by Evident Corporation.

For more information on this source, please visit Evident Corporation.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.