Three key areas exist when discussing marine markets:

- Marine Naval Forces

- Merchant fleets

- Cruise lines

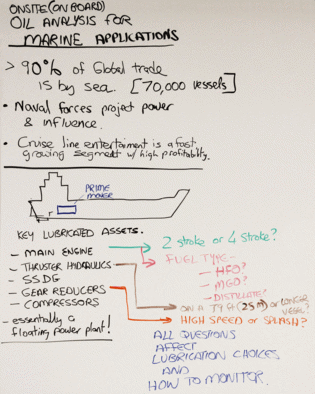

It is vital to remember that this large industry utilizes constant on-site oil analysis to ensure equipment uptime. Ninety percent of worldwide trade is by sea, with around 70,000 vessels transporting goods around the globe.

Naval forces are used by countries to show influence and power. Reliability is crucial, so on board oil analysis is commonly employed. The cruise line entertainment industry is a quickly growing part of the marine market with high profitability, so reliability is important for success.

There is a prime mover in every marine application, which is the main engine, but there are other important lubricated assets on board too. There are thruster hydraulics, gear reducers, backup generators for power, and compressors for air, so it is essentially a floating power plant.

As there are a large number of different lubricated assets, there are numerous different lubricants on board. Types of fuel, engine designs, and types of fluids per regulatory compliance all complicate the monitoring task and so monitoring should be performed on a regular basis.

Ask the Expert: Marine On-site Oil Analysis

Major Challenges

When it comes to the marine market there are three key challenges. The first is overcapacity in shipping with more vessels out on the seas than goods in supply. Merchant lines are managing different approaches in order to reduce costs because of that. A number of those approaches have a negative effect on the reliability of the equipment, which is why on-site oil analysis is crucial, especially with regard to slow steaming issues.

The second key issue is the new sulfur regulation which will be in place in 2020. All the fuels that are generally heavy fuel oils and high sulfur fuels, are changing from 3.5% down to 0.5%. There will be some huge investments made to ensure compliance as a result of that requirement.

There are many challenges relating to fuel quality assurance. There are already existing sulfur emission control areas around the US, Europe, and some areas in China. Ships must now switch from high sulfur fuel to low sulfur fuel when they go into port. It is also important to match the engine lubricant when that switch happens, particularly on two-stroke engines, from a high base number to a low base number.

Lastly, there is the US VGP or Vessel General Permit compliance, which was issued in 2013. This states that any vessel longer than 25 meters or 79 feet must have some compliance where any oils which come in contact with water must be biodegradable; the requirement for rotating equipment to have EAL, environmentally aware lubricants, or biodegradable lubricants is especially tight.

These major issues affect the industry, and mean it is more complicated than ever. Today, on board monitoring is crucial to navigate through these processes.

Fuels and Engines

Two-stroke power is most common in cargo ships. Typically, these engines are built to have a reliable, long life. They are fairly simple to manage overall, but on the larger two-stroke engines, there are two different lubrication systems. There is a once-through cylinder lubrication system, where the compression happens.

As it is the first response and is a neutralizer for those sulfuric acids which are produced when high sulfur fuel is burned, the base number (BN) of the oil is absolutely vital. The system oil itself is the second lubrication system. Essentially, the system oil is separated from the cylinder area and is similar to a traditional four-stroke engine oil application.

There are four-stroke applications which run high sulfurous fuels. In this instance a TPE or trunk piston engine oil is utilized, which has the right additive package to manage those high sulfur fuels, or a regular four-stroke lower base number. Everybody will be moving towards a more conventional system oil or TPE type of environment due to the industry switching from a high sulfur to a low sulfur option.

For the VGP permit requirements, these EAL or biodegradable fluids, require switch out for many of the rotating equipment like hydraulic systems and thrusters which come in contact with water. These water insoluble, or water soluble PAG's/ EAL style vegetable oil based lubricants present must be managed. If they are not managed carefully, they will not possess the same life expectancy.

The drive is to go towards higher synthetic, long-life applications for particular gearbox applications. Though this is more costly at the front end, they can achieve a much longer life if they are monitored extremely carefully.

Recommended Tests

A chart of recommended tests which should be utilized for marine condition monitoring applications and should be performed on a per month basis is detailed above. The major engines discussed are two-stroke and four-stroke, and it is crucial to be able to separate them as there are distinct differences in needs.

The key concern is the base number (BN) and viscosity for the two-stroke engine. That is how the fluid gets to the correct area of the cylinder so it is crucial to ensure that there is enough alkaline reserve there to neutralize any acids which are being generated. Base number in those ranges can be anywhere between 40 to 200 base numbers, which is a very high range.

It is suggested to monitor those numbers continually, both on the incoming lubricant if it is coming right out of the bunker, or if you have a blending on board system. When you have added waste engine oil or system oil as a package to bring up the base number, it should be monitored before it sprays on the cylinders. It is important to keep an eye on the base number once it comes off the cylinders and drips out on the residual drain.

If the number changes dramatically, it indicates the level of sulfurous fuels and the flow rates. Another test to perform is checking the scrape down oil, which is essentially the residual material. The ferrous content should be checked because it indicates the amount of corrosive wear which is generated if the alkaline reserve is incorrect or if there is an incorrect range of treat rate to the cylinders.

Ferrous density is crucial as it involves the large debris which may be popped out of the cylinder wall if excessive wear occurs. Yet, it is not sufficient on its own, and it is vital to observe the corrosive wear. Elemental spectroscopy is recommended in those instances, particularly for those which are corrosive.

The two results combined will indicate total iron content. The ferrous density and base number should be checked to look for any abnormal wear in the case of the system oil which is separate from the cylinder oil. Viscosity is at 40 to 100, (remember this is long life oil which will be kept in the system).

In this situation water content is critical, even though a lot of water can be accommodated. Elemental spectroscopy for elemental wear, additive packages and contaminants, is needed. In the case of regular four-stroke engine oil, ferrous density, base number, and viscosity are vital tests. In addition to elemental spectroscopy, water content is also suggested.

Due to the aforementioned sulfur cap, there will be more engines which are powered by natural gas, or LPG propane based ships. There may be a bigger requirement for total acid number in those situations, which is extremely similar to land-based natural gas compressors where TBN and TAN are necessary.

In the case of rotating equipment, especially thruster hydraulic situations, where mineral or EAL fluids are present, then viscosity, ferrous density, and water content should be tested. The EAL type fluids possess an extremely high capability for water. There can be between four and six percent water, which is up to 60,000 ppm of water. As it is held in solution this is not a problem for the application but it is necessary to be able to measure that and be able to control it.

Since it determines the level of oxidation if there is any hydrolysis or breakdown occurring, total acid number is also vital. Elemental spectroscopy is necessary to establish if there are any wear additives and contaminants present. Particle count is important to determine the overall debris in addition to how well the filters are doing.

For gear systems, since it's a critical point for any large ferrous wear, the recommendations are to measure ferrous density, in addition to viscosity as it is crucial for lube film strength. Water content and total acid number should be checked to observe the long life and oxidation issues.

In addition to particle count, elemental spectroscopy (particularly for pressurized gearboxes or transmission systems) establishes the filter efficiency. It is also crucial to establish any shaped morphology, and one can observe the size in the shape of the material to indicate if any abnormal wear is present.

Compressor systems are extremely similar to gear systems, where it is vital to assess water content, acid number, ferrous density, viscosity, and elemental spectroscopy. Depending on the type of compressor, particle count is optional.

In each of these circumstances for on board applications, the MiniLab Series is recommended. It can be customized to match your specific requirements and can perform all of the tests mentioned in this article.

TruVu 360 is also recommended. It assists in managing the data you analyze on board, and can immediately issue reports. For the merchant fleet concerned with the sulfur cap situation, it is suggested that you explore something for fuel quality assurance, especially when establishing the sulfur content.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.