Written by Joe Nichols, General Plastics Manufacturing Company, Jeremy Milsten, General Plastics Manufacturing Company, and Geoff Veld. General Plastics Manufacturing Company

To ensure public health and safety in normal conditions and during accidents, radioactive material transportation packaging must be constructed from durable materials that meet regulatory requirements.

For nearly 55 years, General Plastics' LAST-A-FOAM® FR-3700 series rigid foam has been used to protect radioactive material containers from damage caused by collision and fire.

General Plastics is now conducting tests to better understand the long-term durability of the LAST-A-FOAM® technology.

This article examines data from samples manufactured 25 years ago as part of a long-term aging study that began in December 1999. The study also compares LAST-A-FOAM® to a range of wood species exposed to the weather.

Wood and polyurethane foams are used as impact limiters and overpacks for radioactive material packaging. These transportation packages are usually certified for decades of use, so materials must keep their physical attributes during the package's regular life span.

This study investigates the aging characteristics of LAST-A-FOAM® and several wood species, as well as their suitability for long-term use.

In December 1999, General Plastics initiated an ongoing investigation of LAST-A-FOAM® and numerous wood species exposed to external conditions. The following presents current findings following 25 years of exposure.

Exposed Storage

Unprotected samples were stored in a subterranean concrete vault with an open grate for the entire year, exposing them to Pacific Northwest weather, dust, dirt, insects, and plant debris (Figures 1, 2, and 3).

After 25 years, the specimens were transported indoors, briefly brushed to remove dirt, and conditioned at 70 ± 5 °F and 50 ± 5 % RH for 40 hours before testing.

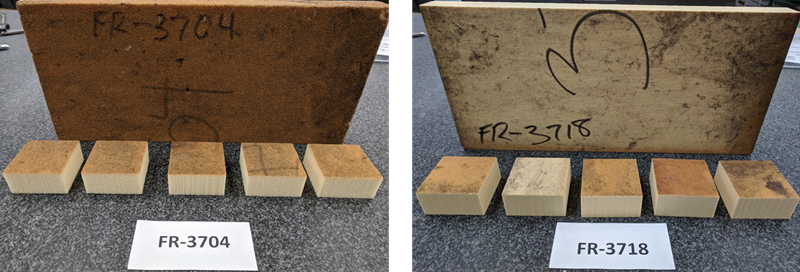

Wood samples revealed extensive degradation due to fungal and insect assault; none were appropriate for cutting test specimens. Foam samples were cut from 1.0" thickness and left "as-is" without cleaning.

Figure 1. Storage location and configuration. Image Credit: General Plastics Manufacturing

Figure 2. Exposed Wood Samples & Exposed Foam Samples. Image Credit: General Plastics Manufacturing

Figure 3. Exposed Wood Samples. Image Credit: General Plastics Manufacturing

Figure 4. Exposed Foam Samples. Image Credit: General Plastics Manufacturing

Data

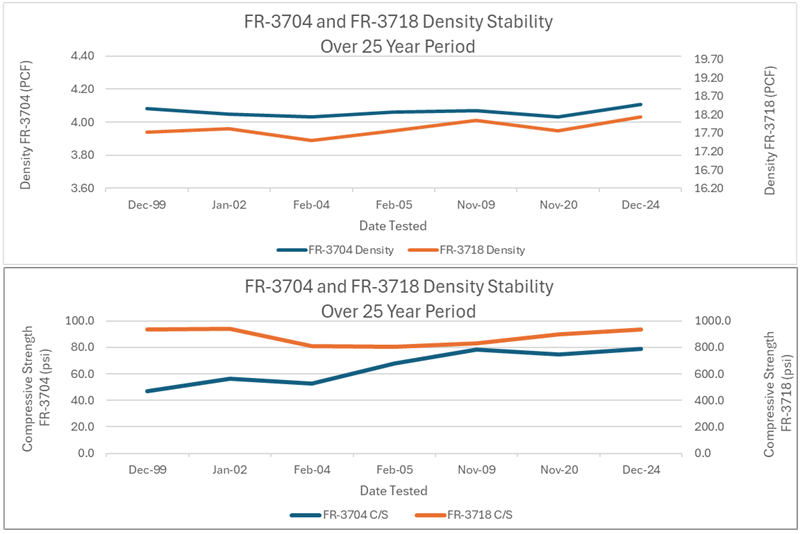

The foam specimens were evaluated parallel to the rise direction. The Shimadzu AG-X Plus 100 kN universal tester was used to assess density and compressive strength in accordance with ASTM D1622 and D1621.

Five samples were tested for each material and condition. The results (Table 1) reveal that density and compressive strength were within typical product variation, with no evidence of degradation due to age or exposure.

Table 1. LAST-A-FOAM® Test Samples and Testing Results. Source: General Plastics Manufacturing

| FR-3704, Exposed Storage |

| Date |

Density (PCF) |

C/S (psi) |

| Dec-99 |

4.08 |

46.9 |

| Jan-02 |

4.05 |

56.6 |

| Feb-04 |

4.03 |

52.9 |

| Feb-05 |

4.06 |

68.0 |

| Nov-09 |

4.07 |

78.3 |

| Nov-20 |

4.03 |

74.9 |

| Dec-24 |

4.11 |

78.9 |

| Average |

4.06 |

65.2 |

| Std. Dev. |

0.03 |

12.1 |

| FR-3718 Exposed Storage |

| Date |

Density (PCF) |

C/S (psi) |

| Dec-99 |

17.73 |

936.1 |

| Jan-02 |

17.82 |

940.7 |

| Feb-04 |

17.50 |

810.7 |

| Feb-05 |

17.77 |

806.3 |

| Nov-09 |

18.05 |

829.6 |

| Nov-20 |

17.77 |

900.4 |

| Dec-24 |

18.15 |

936.4 |

| Average |

17.83 |

880.0 |

| Std. Dev. |

0.20 |

57.6 |

Figure 5. Foam Density and Strength over 25 years. Image Credit: General Plastics Manufacturing

Discussion

These storage circumstances exposed samples to significantly harsher environments than foam would normally encounter inside an essentially hermetically sealed impact limiter.

After 20 years, neither the density nor the compression strength of the LAST-A-FOAM® material decreased significantly.

The FR-3704 appears to have gained strength in measurements taken after 2004, but we believe the test apparatus was upgraded, causing the apparent upward movement in strength. The FR-3704's strength has been largely consistent during the previous 20 years.

The FR-3718's greater testing loads appear to be less sensitive to test apparatus difficulties, and they have remained highly stable over the last 25 years. The exposed LAST-A-FOAM® products exhibited the expected yellowing of polyurethane products due to UV exposure.

The problem was limited to the surface alone.

The 21-year-old sliced specimens exhibited pristine material, as one would expect from newly created material. Any moss development discovered on the LAST-A-FOAM® material was maintained by the underlying organic matter of leaves, dust, and dirt rather than the foam substance.

The foam state was consistent with earlier independent fungal studies, which show that LAST-A-FOAM® products do not support fungal development. (See ASTM G21 and MILSTD-810G1 Method 508.7).

According to the 20-year update (copies available upon request), the wood samples showed varying instabilities in density and compression strengths after 20 years of exposure. As expected, and as documented in the 20-year study, none of the wood samples were in sufficient condition for testing.

As expressed in the graphical results, the foam is exceptionally resistant to rigorous environmental and biological exposure and performs more consistently than wood.

While darkening and soiling of the LAST-A-FOAM® exterior surfaces may occur, the material's closed-cell structure prevents environmental impacts from extending beyond the exposed surfaces. Upon investigation, all foam samples were found to be virgin material and had no adverse effect on mechanical performance.

Conclusion

LAST-A-FOAM® has proven reliable in applications requiring long-term material stability, both under sheltered and harsh exposed circumstances. Unlike wood, it does not decay or lose mechanical integrity, guaranteeing that radioactive materials are transported and stored safely throughout the package's approved life.

This information has been sourced, reviewed, and adapted from materials provided by General Plastics Manufacturing.

For more information on this source, please visit General Plastics Manufacturing.