General Plastics typically uses multiple pour-in-place processes when filling nuclear packaging impact limiters or over packs with LAST-A-FOAM® FR-3700 series of material.

It may be necessary to conduct two or three pour increments to fill a cavity of just a few cubic feet in some units, while other larger units demand more than a dozen pour increments of 500 lbs. per pour to fill more than 450 ft³ for a single unit.

The advantages of this multiple-pour process are that it controls the exothermic heat, reduces the internal pressures produced throughout the foam expansion and limits density variation throughout the filled unit. This process results in knit lines or pour layer boundaries between the layers of foam.

A frequently asked question of this process is whether the overall compression strength properties of the entire polyurethane foam structure are compromised by these boundary layers within a limiter or over pack.

Experimental Conditions

General Plastics reviewed the compression strength data between multiple samples of FR-3700 series foam tested at various densities that exhibited a knit line as a result of multiple pours. This data was contrasted against that of a homogeneous sample with no knit line.

To produce knit lines between fully cured layers of foam, preparation of foam samples was conducted in 13”x13” boxes in multiple pours.

See photo #1 for a box pour exhibiting three pour increments, with two knit lines created by the foam-to-foam pour boundary line. The homogeneous sample was also established in a 13” x 13” box. Samples were cut from both the homogeneous block and the multi-layered blocks. The blue dotted line is positioned next to the knit line.

Prior to testing, all samples were conditioned for at least 40 hours at 70 +/- 5°F and 50 +/- 5% Relative Humidity. Samples were tested as free samples, with no lateral limitations or features to restrict the movement of the foam.

Testing of the five samples for each density and configuration was conducted at 15% strain, and the maximum compressive strength recorded up to 10% strain. Densities of 5, 10, 18, & 30 lbs./ft.³ were evaluated.

Photo #1: Box pour with three pour increments. Image Credit: General Plastics Manufacturing Company

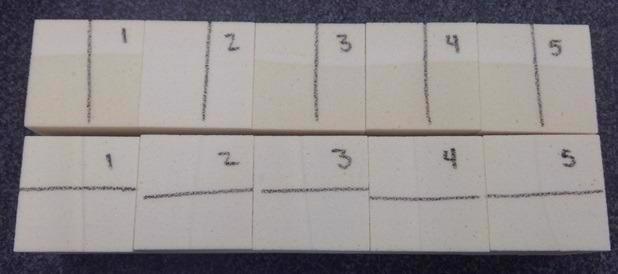

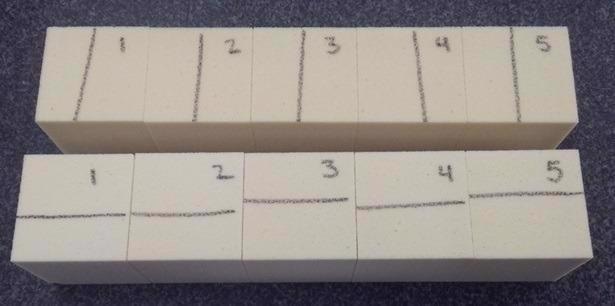

Photo #2: Parallel and Perpendicular specimens, pre-test. Image Credit: General Plastics Manufacturing Company

Photo #3: Specimens with knit line at 45°, pre-test. Image Credit: General Plastics Manufacturing Company

Photo #4: Homogeneous foam, no knit line, pre-test. Black marker indicates direction of foam rise. Image Credit: General Plastics Manufacturing Company

Compression testing was conducted on samples with knit lines aligned parallel, perpendicular, and at 45o to the load’s direction. Additional samples were produced that contained no knit lines and were also tested perpendicular and parallel to the direction of foam rise.

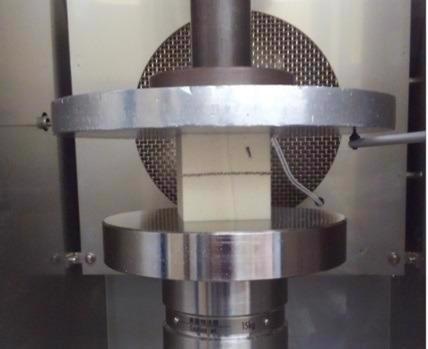

Density tests were carried out in accordance with ASTM D-1622, using a digital caliper and scale. A Shimadzu AG-X Plus 100 kN Universal Testing Machine was used to follow ASTM D-1621 for compressive strength testing. See Photo #5.

Photo #5: Typical compression test setup. Image Credit: General Plastics Manufacturing Company

Data

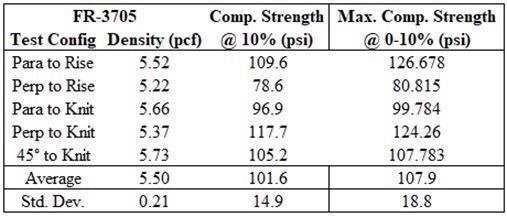

The results for each configuration and foam density are shown in Tables 1-4.

Table #1: FR-3705. Source: General Plastics Manufacturing Company

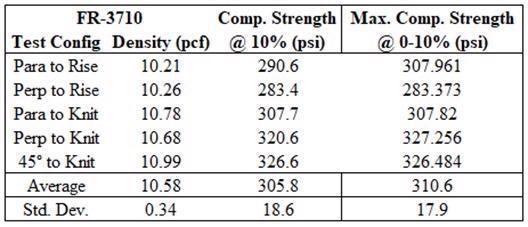

Table #2: FR-3710. Source: General Plastics Manufacturing Company

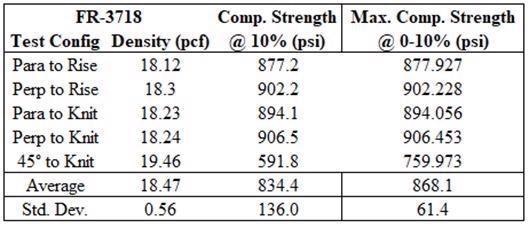

Table #3: FR-3718. Source: General Plastics Manufacturing Company

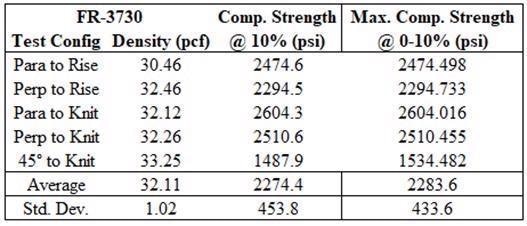

Table #4: FR-3730 Source: General Plastics Manufacturing Company

Discussion:

Knit lines oriented either perpendicular or parallel to the direction of force displayed no specific failure modes or considerable deviations from strengths witnessed in homogeneous foam samples.

For samples tested at 45° to the knit line, the FR-3705 and FR-3710 specimens only demonstrated deformation and did not display shear failures at the boundary layers. The maximum compression values were within the expected range of variation in contrast to the homogeneous foam samples tested in both parallel and perpendicular directions to the foam’s rise.

In contrast to the homogeneous foam samples of the same density, the FR-3710 demonstrated higher compression values.

See Photos #5 and #6.

Photo #5: Slight deformation at the knit line, but no shear failure. Image Credit: General Plastics Manufacturing Company

Photo #6: Slight deformation at the knit line, but no shear failure. Image Credit: General Plastics Manufacturing Company

Shearing at the boundary layers in the higher density foams tested with the load 45° to the knit line resulted in a drop in compressive strength. The FR-3718 encountered a 31.5% drop in strength at failure and the FR-3730 39.3%. See Photos #7 and #8.

Photo #7: FR-3718 after compression test. Shear at the boundary layer knit line. Image Credit: General Plastics Manufacturing Company

imilarly, the shear condition appears to be what would be anticipated with a conventional adhesive bond line. An adhesive can be stronger or weaker than the material it is bonding. As the density of the foam increases, it appears that the relative compressive strength starts to exceed the knit line’s strength. This is seen to occur between the density range of 10pcf and 18pcf.

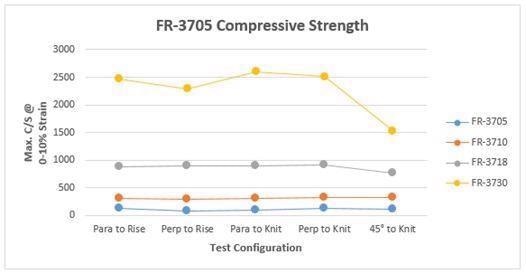

Graph #1 exhibits all test conditions for all densities of foam. It is clear to see that the tendency to shear at the 45° knit line relates to the higher density foam.

Graph #1. Image Credit: General Plastics Manufacturing Company

It is necessary to note that foam material poured in situ or foam blocks constructed and positioned into a transportation unit would be restrained within the container if an impact or crush were to occur, limiting the movement of the foam.

When installed in a transportation unit, this unconstrained condition of compression testing does not always represent the conditions. The intention of these tests is to review how the foam and its boundary layers act in the unconstrained condition.

Conclusion

The study demonstrates that incremental pours and the resulting knit lines perform in the same way that assembled units with bonded blocks are likely to act. Using incremental layers of LAST-A-FOAM® when pouring double-walled units, the limitations of the sidewalls would not permit the lateral or shearing movement of foam, should an impact approach a knit line at 45°.

Forces exerted perpendicular or parallel to a knit line would react in a similar fashion to an impact on homogeneous foam.

Pour-in-place nuclear packaging is comprised of multiple pours producing knit lines, leading to the relative dimensional stability and performance that comes with filling utilizing a single monolithic foam pour.

Discussion

Nuclear transportation packaging can experience several modes of compression or ‘crush’ stresses.

Whether these stresses are from rigorous 10 CFR 71.73 testing or as a result of an actual accident, in situ pouring affords designers the option and confidence of filling complex nuclear transportation packaging with LAST-A-FOAM® polyurethane foams. Thus, providing the knowledge the foam will offer the equivalent performance of that of a monolithic, homogeneous foam structure.

This information has been sourced, reviewed and adapted from materials provided by General Plastics Manufacturing.

For more information on this source, please visit General Plastics Manufacturing.