Ensuring that gas leaks from the United States’ natural gas networks are monitored, managed and addressed in a timely manner has been historically challenging. The network’s pipelines travel through a varied range of terrains, including cities and towns of varying sizes.

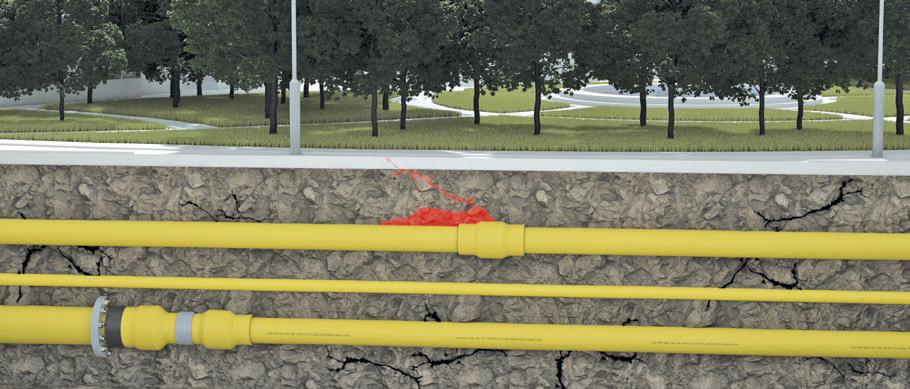

Gas leaks from underground pipelines can remain hidden from insensitive technology and create dangerous conditions under a city street. Image Credit: ABB Measurement & Analytics

Advanced technological developments from ABB are helping to address this issue, facilitating the rapid and accurate tracing and quantification of leaks, empowering operators to develop targeted, optimized and effective leak repair strategies.

Natural gas remains a commonly used energy source for US-based residential, commercial and industrial consumers. Natural gas currently accounts for approximately 40% of the country’s energy mix, 60% of which is still dependent on fossil fuels.

Natural gas transportation is achieved via pipeline networks that span many thousands of miles, with large-scale distribution lines transporting the gas close to cities and areas where it is needed most.

The American Petroleum Institute1 states that a combination of these main gas lines and the smaller service lines that transport gas directly to homes and businesses account for most of the country’s 2.4-million-mile underground pipeline system.

The size and extent of these large, wide-ranging networks mean that their structural integrity can be impacted by a number of factors, with gas leaks an inevitable and frequently encountered issue.

Leaking gas pipelines in towns and cities can occur at any point in the network, including pipelines under buildings and streets. There are a number of potential causes of these leaks, including:

- Accidents during excavations resulting in a pipeline becoming ruptured, nicked or punctured

- Heavy materials or equipment being placed over buried pipelines

- Water main leaks that weaken pavements and roadways

- The accumulation of excess snow and ice on gas pipes, meters and gas appliance exhaust and combustion air vents

- Explosions or fires close to a pipeline

- Too much or too little pressure in the gas system

- Equipment corrosion or outright failure

- Natural disasters, including hurricanes, floods or earthquakes

Implications of Gas Leaks

Gas leaks are a serious issue with potentially catastrophic environmental, safety and cost implications.

Safety Implications

Gas leaks have the potential to cause serious injuries and even fatalities in many cases. A gas line explosion in Samut Prakan, Thailand, in October 2020 killed three people and injured 28. The explosion occurred on a natural gas line that was owned by the state-owned oil and gas company PTT PCL.3

Gas leaks also frequently pose a wider risk in local communities, with incidents such as the Buncefield gas storage facility explosion in the UK in 2005 and the San Bruno pipeline explosion in the USA in 2010 illustrating the danger that the escape of explosive gases can have on the public.

Environmental Implications

The Environmental Defence Fund (EDF)2 recently found that the operations by the U.S. oil and gas industry emit approximately 13 million metric tons per year – a total that is almost 60% more than the US Environmental Protection Agency (EPA) currently estimates.

Gas pipeline leaks are a major contributor to this figure. Methane is a potent greenhouse gas with a 100-year global warming potential that is between 28 and 34 times higher than that of carbon dioxide.

Methane has been highlighted as one of the primary drivers behind Earth’s growing climate crisis, with organizations and governments around the world working to target and lower emissions.

As gas pipelines are a key source of emissions, the US introduced ‘Protecting our Infrastructure of Pipelines and Enhancing Safety Act’ (PIPES 2020). This legislation requires oil and gas operators to implement routine leak detection and repair programs to ensure the integrity of their gas distribution networks.

The legislation specifically instructs operators to implement programs that can identify and categorize leaks with the potential to pose a risk to human life or the environment. Programs are also required to identify any risk of explosion or other hazards.

Cost Implications

Leaking pipelines also cause billions of dollars of lost revenue annually, in terms of both direct product loss and the cost and time implications involved in replacing this.

Tracking Leaks

Gas transportation infrastructure in the US is aging – a key challenge in maintaining its efficient operation. For example, more than half of New York’s gas mains were installed prior to 1960,3 and these are manufactured from corrosion-prone unprotected cast iron.

Gas leaks can result in a significant risk to life and significant environmental and financial implications. To safeguard the public and minimize any environmental risks, city gas distribution networks must be subject to stringent leak detection and monitoring on an ongoing basis.

Disadvantages of Traditional Leak Detection Methods

Gas leak detection systems are essential in ensuring that the source of a leak is detected promptly when this occurs, but traditional methods tend to be slow, inaccurate and insensitive.

It is often necessary for technicians to walk around the area being inspected in a methodical manner, employing handheld detectors which must be calibrated once on site – a process that can take up to 45 minutes.

These systems only test the air every few seconds, meaning that the technician must traverse the suspected leak site extremely slowly. They must also enter test results manually into reporting systems, extending the time required to complete the process.

Newer, more advanced systems are available, however. These systems have the potential to revolutionize the rapid and accurate detection and identification of gas leaks.

Next Generation Gas Leak Detection Systems

A number of gas leak detection solutions offering significantly improved performance over traditional methods have been developed thanks to recent advances in sensing, analytics and mobile technology.

One example solution is the ABB Ability advanced gas detection platform. ABB Ability was developed using the innovative LGR-ICOS™ technology and represents the current evolution of tunable diode laser spectroscopy.

The system is more than 1,000 times as sensitive as many legacy sensors, allowing operators to accurately detect gas leaks even hundreds of feet from their source.

The ABB Ability platform forms the foundation of several robust gas leak detection systems, including:

- MobileGuard™ - A high speed vehicle-based mobile gas leak detection system

- MicroGuard™ - A highly portable gas leak detection system

- HoverGuard™ - An extremely portable UAV-based gas leak detection system

- EverGuard™ - A robust always-on stationary gas leak emissions monitoring system

ABB’s natural gas leak detection platform. Image Credit: ABB Measurement & Analytics

MobileGuard™

ABB’s MobileGuard™ is a vehicle-mounted system that has been developed to facilitate accurate natural gas leak detection from roadways. It employs a combination of an LGR-ICOS™ analyzer and an ultrasonic anemometer to measure windspeed alongside a GNSS antenna designed to measure location.

Once it has recorded this data, the MobileGuard™ system leverages the power of advanced algorithms to combine this with gas concentration measurements to locate, map and quantify the size of pipeline leaks.

MobileGuard™ is able to achieve this accurate measurement and localization from a moving vehicle, even when this is far from the emission source.

By acquiring several measurements a second, the system is able to conduct accurate leak surveys while driving at speeds of up to 55 mph. This speed and accuracy allow surveyors to cover between 10 and 25 times more land area per minute than can be covered using conventional methods.

The analyzer is able to measure methane and ethane concentrations, meaning that it can differentiate between pipeline gas and naturally occurring methane. It is therefore unlikely to return a false positive result.

The MobileGuard™ system performs data analysis locally in order to present the user with geospatial maps of the full range of measured parameters in real-time. It is also possible to securely relay data and analyses to cloud storage for easy sharing and additional analysis.

MobileGuard™ ready to perform natural gas survey with a technician pinpointing gas leak with MicroGuard™. Image Credit: ABB Measurement & Analytics

MicroGuard™

MicroGuard™ utilizes the ultrasensitive detector technology employed in the MobileGuard™ system that is specifically optimized for walking surveys.

The system is comprised of an LGR-ICOS™ gas analyzer, backpack and a ruggedized tablet that features a Global Navigation Satellite System (GNNS). The system also features proprietary software and a custom-designed sample wand.

Using the MicroGuard™ system, walking surveyors are able to accurately and easily pinpoint natural gas leaks within a matter of minutes. The system’s software generates comprehensive digital survey reports, which can be shared instantly.

HoverGuard™

The HoverGuard™ system is an advanced UAV-based gas leak detection system. This flying drone-based system is able to sample the air five times per second, offering advantages over other techniques, including improved speed, accuracy and rapid data collection.

This solution also combines an anemometer and Global Navigation Satellite System (GNSS) sensor to collect data on wind speed and position, enabling the precise location of a leak to be determined.

This data is collated with information from advanced mapping software to produce comprehensive reports on leak locations. Data can be shared via the cloud or directly, meaning that reports are readily available to enable pipeline operators to develop robust find-and-fix strategies.

Image Credit: ABB Measurement & Analytics

EverGuard™

The EverGuard™ system offers ongoing, ultrasensitive monitoring of natural gas emissions. It has been ideally designed to be installed close to high-risk areas such as schools, hospitals and areas where there are large public gatherings.

The system is comprised of ABB’s highly regarded microportable multi-gas analyzer (GLA131 Series), installed in a weatherproof NEMA 4X enclosure.

This enclosure can be linked to a number of optional modules, including a GNSS receiver, weather station, solar panel, uninterruptible power supply, cellular transmitter, Wi-Fi router or multi-inlet sampling manifold.

With a diverse array of customization options available, the EverGuard™ system is able to meet the most demanding requirements of virtually any application involving the continuous monitoring of natural gas leaks.

The system can employ secure wireless communication and internet connectivity to enable local and remote communication, allowing users to remotely and immediately access vital data. This ensures full transparency and is designed to meet all relevant compliance requirements.

Continuous Improvement

The advent of digitalization has revolutionized the practices and technologies surrounding natural gas leak detection, facilitating exponential improvements in cost, sensitivity, accuracy and speed.

The ABB Ability platform and its family of solutions represent a vital toolkit in the ongoing fight against potentially dangerous gas leaks.

While it is impossible to eliminate gas leaks entirely, organizations must employ the most accurate, up-to-date and reliable gas leak detection technology to address gas leaks as quickly and safely as possible.

References

- API | Where are the Pipelines?

- New Study Finds U.S. Oil and Gas Methane Emissions Are 60 Percent Higher Than EPA Reports | Environmental Defense Fund (edf.org)

- Caution Ahead (nycfuture.org)

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.