With its diverse portfolio of polymer testing and sensing equipment, Dynisco is bringing rheology to the masses.

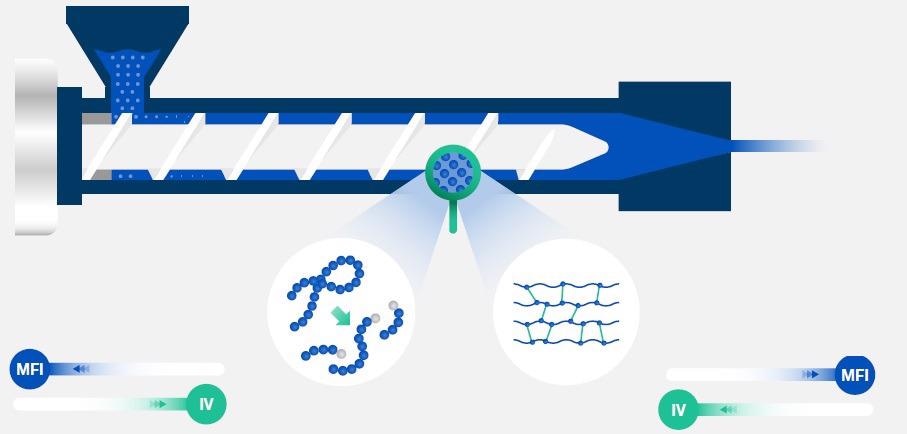

Rheology is the investigation of the flow and deformation behavior of materials when forces are directly applied to them. MFI and IV are sensitive to the thermomechanical degradation of polymers and, as a result, are critical parameters for quality control throughout the plastic extrusion process.

Image Credit: Dynisco

Rheological Measurements and the Plastic Extrusion Process

Polymer degradation has an immediate impact on the final plastic product and its properties. In the plastic extrusion process, increased temperatures, as a result of the melt processing, in combination with the time that polymers spend in the barrel, can influence the molecular weight of the extrudates.

The mechanical shear from the screw’s rotation, especially in cases of rapid extrusion, can lead to degradation and chain scission in polymer molecules.

Scission of long molecules, as a result of degradation, relates to an increase of MFI or a decrease in the overall IV level. On the other hand, degradation can also lead to cross-linking of decomposed polymers, which can lead to an increase in IV or a decrease in MFI.

Conducting rheological measurements of a compound before, during and after the melt processing is an effective way to identify if any thermomechanical degradation has taken place throughout the extrusion process

Image Credit: Dynisco

Why is it Important to Avoid Degradation and Keep Polymers in Specification?

Polymer degradation has an immediate impact on the characteristics of the final plastic product.

Changes in molecular weight impact short-term and long-term characteristics such as fatigue resistance, impact resistance and environmental stress cracking resistance.

As recycling standards state that corporations must incorporate a certain percentage of recycled content, it is vital to keep producers’ reprocessed scrap or the purchased recycled material as close as possible to their pure product’s specifications to preserve quality.

Also, the polymer is a “blind item.” Recyclers and manufacturers are not able to determine the polymers’ specifications just by visual inspection alone.

Image Credit: Dynisco

Verification of the rheological properties of polymers is critically important to minimize degradation during the recycling process and to ensure that the polymer does not degrade and negatively impact the quality of the product

Image Credit: Dynisco

It can offer companies access to precise information to validate and adjust their process as necessary to ensure the products they produce meet or exceed their specifications. This is critically important as plants typically process tens of thousands of pounds of material at a time.

Without access to real-time knowledge of the rheological properties of the materials, manufacturers could potentially produce subpar products without even realizing it and, consequently, waste time and money while sacrificing process consistency.

Dynisco’s range of polymer testing equipment, particularly both the Melt Flow Indexer and the ViscoIndicator Online Rheometer, offer access to some of the most accurate information on the market for measuring polymer rheology, pressure and temperature.

Dynisco Melt Flow Indexers

Melt flow indexers offer plastics processors and recyclers priceless information that either validates the specifications or characteristics of a polymer on a polymer datasheet or, in the case of recycled material, lets operators know the current MFI or IV of the recycled plastic.

The Dynisco LMI5500 melt flow indexer can measure the MFI and safely deduce the IV of PET or RPET without the need for hazardous chemicals.

This enables recyclers and processors to accurately determine the IV of their PET and make sure the material is up to the standard required for their application. Knowing the IV can help make crucial adjustments to the process to guarantee quality.

LMI5500 can also work with Dynisco’s ViscoIndicator Online Rheometer, which has the capacity to measure the IV and MFI of the polymer melt every 15 seconds, meaning processors can adjust the process parameters (percentage of regrind, resin drying or add additives) and make sure the end product is consistent in quality.

Image Credit: Dynisco

ViscoIndicator Online Rheometer

Introducing a Dynisco ViscoIndicator Online Rheometer to standard extruders facilitates complete lot-to-lot measurement of the production run while giving processors the ability to transmit an automatic signal to the blender or extruder for in-situ adjustment of the production line.

The ViscoIndicator was developed in a way that precisely replicates the standard testing condition of melt flow rate testing. The ViscoIndicator offers useful plastics information on melt flow index or viscosity values.

The most frequently used standards for melt flow rate testing are ASTM-D1238 and ISO 1133, which set the standard conditions such as temperature and weight for a distinct material.

This passes the challenges of melt flow rate simulation in an online rheometer onto an extruder since the processing temperature can vary from that of standard ASTM/ISO temperatures in a melt flow rate tester.

The ViscoIndicator can supply accurate and continuous real-time MFI readings related to extruded materials at the standard ASTM/ISO temperature, irrespective of the processing temperature, by taking into account the temperature dependency of the melt flow behavior of plastic materials.

It also means that processors working in any manufacturing or recycling industry are able to ensure quality on a consistent basis by modifying critical inputs of the process, such as:

- Adjustment percentage of virgin vs. recycled material

- Adding additives to maintain polymer specifications

- Transmitting control signals to adjust production parameters, such as screw speed and temperature, based on current rheology measurements

IoT Cloud Connect

Dynisco now manufactures products that can be combined with data science. Apply Dynisco IoT Cloud Connect’s™ insights today and make better decisions tomorrow. IoT Cloud Connect™, for example, offers a clearer view into processes and can help users discover new insights previously unnoticed.

Image Credit: Dynisco

All test samples can be viewed by phone, tablet or PC using the Dynisco IoT Cloud Connect™. This is where polymer data can be stored and compared using any device, production run, operator and global location. The aggregation of data offers clear insight into the process and helps users better understand and manage:

- Control strategies that modify the process to enhance material quality

- Environmental conditions that lead to variations in test or production process

- Material verification at each stage of the process using correlations

- Variations in the properties of plastic that impact product quality

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.