Sponsored by TOFWERKReviewed by Emily MageeJun 21 2022

The accurate measurement of airborne molecular contaminants (AMCs) is critical for establishing effective process controls for semiconductor manufacturers. The effects of foreign molecular contaminants become increasingly detrimental to wafer production yields as node technologies continue to advance, increasing in complexity and reducing in size.

Carla Frege, Felipe Lopez-Hilfiker, Ben Bensaoula, Liang Zhu TOFWERK, Switzerland. Image Credit: TOFWERK

Manufacturers of both small and large node technologies alike are being forced, by growing concerns related to material supply chains, to pursue improvements in the monitoring of AMCs, in order to implement effective preventive maintenance schedules that ensure optimum wafer yields and reduce downtime.

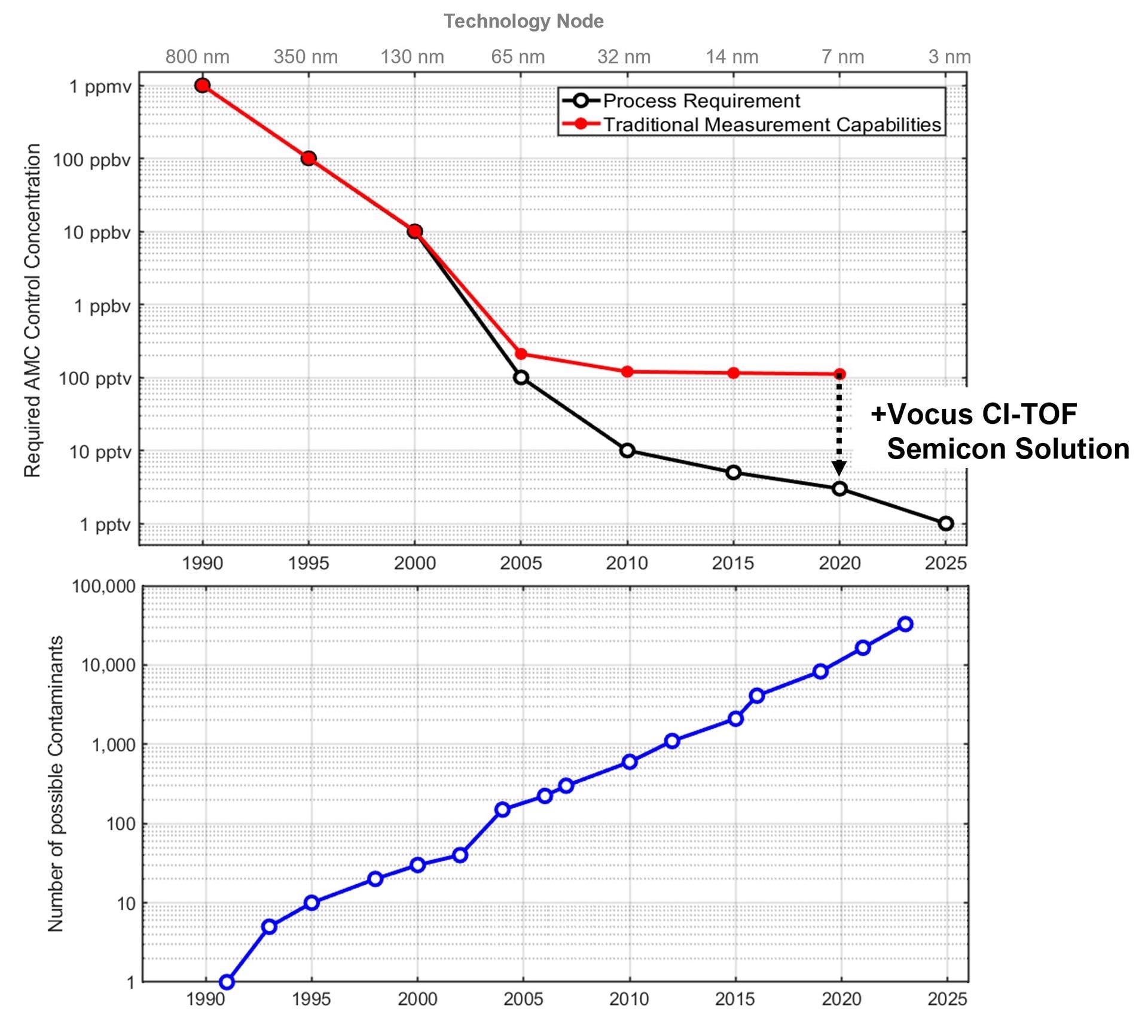

There are emerging demands for higher performance analytical instruments that report AMC concentrations, along with the advancement of production processes and machines. Contaminants at parts-per-trillion volume (pptv) concentrations need to be inventoried in order to ensure stringent control over the macro and micro manufacturing environment. An ultra-fast instrument response is required to both provide alarm at early-stage AMC incidents and increase the sample throughput.

Micro contamination attributed to the ambient air quality comprised of both external (make-up air) and internal (e.g., tools, chemicals, workers, material coatings) sources impacts the semiconductor manufacturing processes1. AMC complexity is increased by cross-contamination between ambient, process and storage environments.

Even though many sources can be identified; many are still difficult to understand and their impact on semiconductor fabrication (fab) remains largely unknown. For contaminants at single-digit pptv sensitivity, the availability of real-time, comprehensive measurements has not been widely implemented nor is readily available. The Vocus CI-TOF, for this reason, shows promise as a powerful tool in the laboratory environment.

The most important AMC categories are reviewed here, including their impact on fab, and AMC monitoring is demonstrated under different scenarios with the Vocus CI-TOF.

Figure 1. Upper – Changes in technology have drastically reduced required AMC control concentrations across time. The capabilities of traditional AMC measurement techniques have not kept pace. The Vocus CI-TOF closes this gap. Lower – The number of AMC contaminants is increasing as the industry reduces feature size. Image Credit: TOFWERK

Airborne Molecular Contaminants

Airborne molecular contaminant is the generic name given to any substance in the form of a gas or aerosol that compromises the manufacturing process. The International Roadmap for Devices and Systems (IRDS) introduced definitions for AMC categories in 2007: molecular bases, molecular acids, dopants, refractories, and condensables. In their 2017 edition, ten years later, it was recognized that, as more contaminants were discovered that did not fall into any of these categories, this approach was not sufficient.

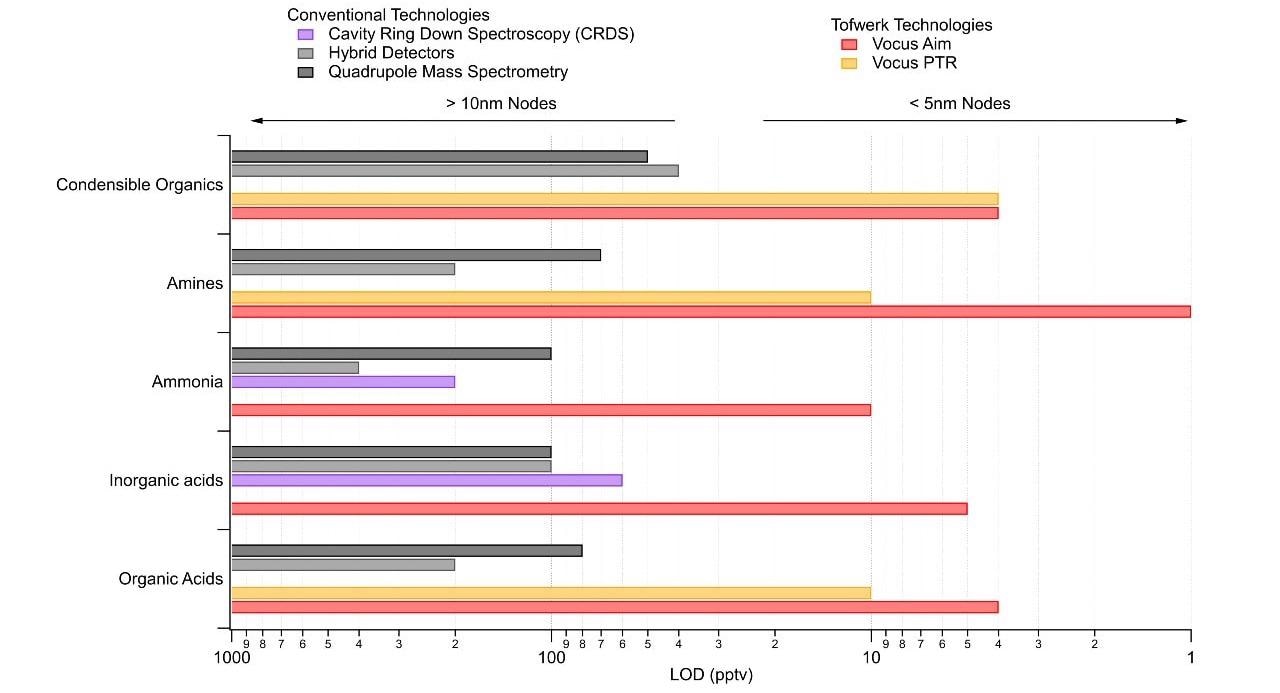

Currently, technologies that are used for AMC detection are limited either by poor compound coverage and/or duty cycle. Despite being used less frequently, chromatographic techniques persist even with their high maintenance costs and their 30-minute temporal resolution. Other online methods measure compounds based on the extinction of their specific wavelength, such as cavity ring-down spectroscopy (CRDS), which therefore limits the performance to measuring just one, or a couple of compounds, and reporting every few minutes. As we can therefore see, the majority of currently-available and deployed technologies are restricted to measuring only one AMC category.

A state-of-the-art solution for AMC monitoring, the Vocus CI-TOF combines all your measuring needs into one instrument: semiconductor manufacturers can measure several AMC categories in real-time and simultaneously with single-digit pptv detection limits.

The full mass spectra acquisition of Vocus improves retrospective analysis when new target compounds become of interest. The Vocus CI-TOF is ideal for monitoring the most complex and demanding AMC environments, guaranteeing constant and precise air quality measurements that are applicable to a variety of fab processes.

Figure 2. Comparison of Vocus CI-TOF and other technologies used for AMC monitoring. Image Credit: TOFWERK

Molecular Acids (MAs)

A problem arises for semiconductor manufacturers in the form of the influence that acids have on wafer yields. Inorganic acids are particularly relevant here, as they contribute to foreign deposition on wafer surfaces; they corrode metallic lines and pads, as well as hazing lithography masks, and deteriorating HEPA filters.

The degradation of HEPA filters can lead to a number of unsatisfactory results and issues, including the generation of unwanted boron species and insufficient sanitization, amongst other effects that are detrimental to production instruments, manufacturing processes, and final products.

Given that solutions offering real-time, comprehensive measurement of inorganic and organic acids with single-digit pptv sensitivity are not currently widely implemented or available, the full effects of trace acid concentrations in the fab remain uncertain.

As is listed in the International Technology Roadmap for Semiconductors (ITRS) 2017 report, current state-of-the-art methods for acid detection offer only limited sensitivity (>100 pptv), whilst for most fab areas practicing 5 nm processes or better <5 pptV presence of total inorganic acids are required.

The Vocus CI-TOF provides precision MA monitoring with single-digit pptv LODs, greatly outperforming currently deployed techniques.

Molecular Bases (MBs)

A special category is composed by AMC compounds, ammonia, amines, and amides. Rapid acid-base reactions result from the basic property of these compounds, forming small salt particulates that deposit unwanted material on various fab surfaces. In addition, persistent fab contamination risk arises because ammonia exhibits a strong affinity for metal surfaces such as copper.

Although ammonia remains the dominant base, the deterioration of lithographic performance and uneven etching can be caused by various amines and amides can also be observed in fab processes,

Therefore, to understand their full impact on the manufacturing process and elect the most efficient abatement strategy, reporting individual bases is required.

It has been demonstrated by measurements with the Vocus CI-TOF that generally MBs persist on FOUP surface materials longer than acids. The formation of new particulates - a process known as nucleation that can occur in the fab – is caused by reactions between MBs and MAs at extremely low concentrations. The simultaneous monitoring of both MBs and MAs is critical for this reason.

Trace levels of Mas and MBs are registered in seconds by the Vocus CI-TOF, allowing manufacturers to elect the most efficient protocols to optimize FOUP cleaning.

Volatile Organic Compounds (VOCs) and Molecular Condensables (MCs)

Plasticizers, phosphates, antioxidants, siloxanes, and VOCs are all included in this AMC category. Salt formation on wafer surfaces, a process known as hazing is contributed to by the presence of VOCs.

The hydrolysis of acetic acid derived from methyl ether acetate (PGMEA), for instance, has been recorded to cause hazing. It has also been demonstrated, on the other hand, that refractive organosilicons change the light scattering properties of optical lenses when they deposit during the lithographic process1. Even in the most challenging conditions, the use of the Vocus CI-TOF for measuring these AMCs has been shown to elicit high accuracy and sensitivity.

AMC Detection Use Cases

In the different areas of the fab, the strategic placement of the Vocus CI-TOF allows for the effective monitoring of environmental conditions in order to minimize production failures associated with contamination and improve control. The Vocus CI-TOF provides results in real-time (seconds) thanks to its high sensitivity and ultra-fast time response while maintaining high throughput to reduce queue times between processes.

These characteristics favor a diversity of fab applications, including AMC control at the process and tool level, FOUP research and development, FOUP monitoring, air chemical conditioning, forensic failure identification and remediation, material optimization, exhaust monitoring, leak detection, quality control and establishing AMC baselines.

Cleanroom Monitoring

For environmentally sensitive materials (microelectronics) and processes (wafer fabrication), cleanroom design aims to maximize production yields4. Cleanrooms are classified based on the number and size of particles allowed per volume of air, due to the need for a high degree of cleanliness when manufacturing semiconductors. In order to meet stringent classification standards and ensure a high production yield, measuring airborne particle precursors becomes critical.

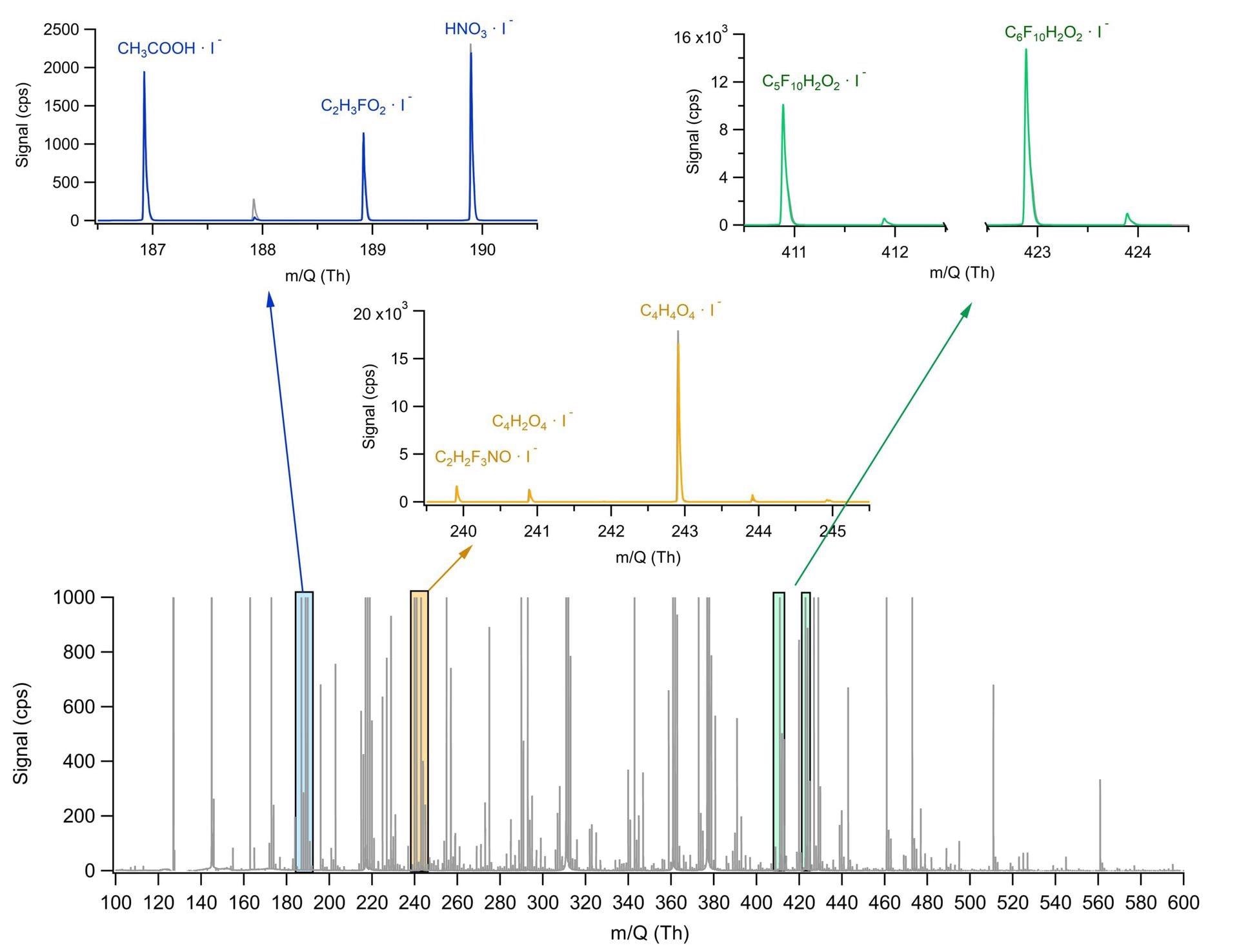

A diversity of sources can result in cleanroom contamination, including ventilation systems, people, and material off gassing. Many compounds are still detected with the Vocus CI-TOF even in the most pristine cleanroom environment. Figure 3 displays an example of Vocus CI-TOF measurements in an ISO 6 cleanroom.

A wide variety of compounds of different AMC categories, including inorganic acids, fluorinated compounds, and VOCs (with several PFAS) were sampled simultaneously.

Figure 3. Example mass spectrum from a cleanroom ISO 6. Several compounds are monitored simultaneously, independent of their AMC category or mass. Low mass molecules (blue), medium mass molecules (yellow) and high mass molecules (green). Image Credit: TOFWERK

Material Outgassing

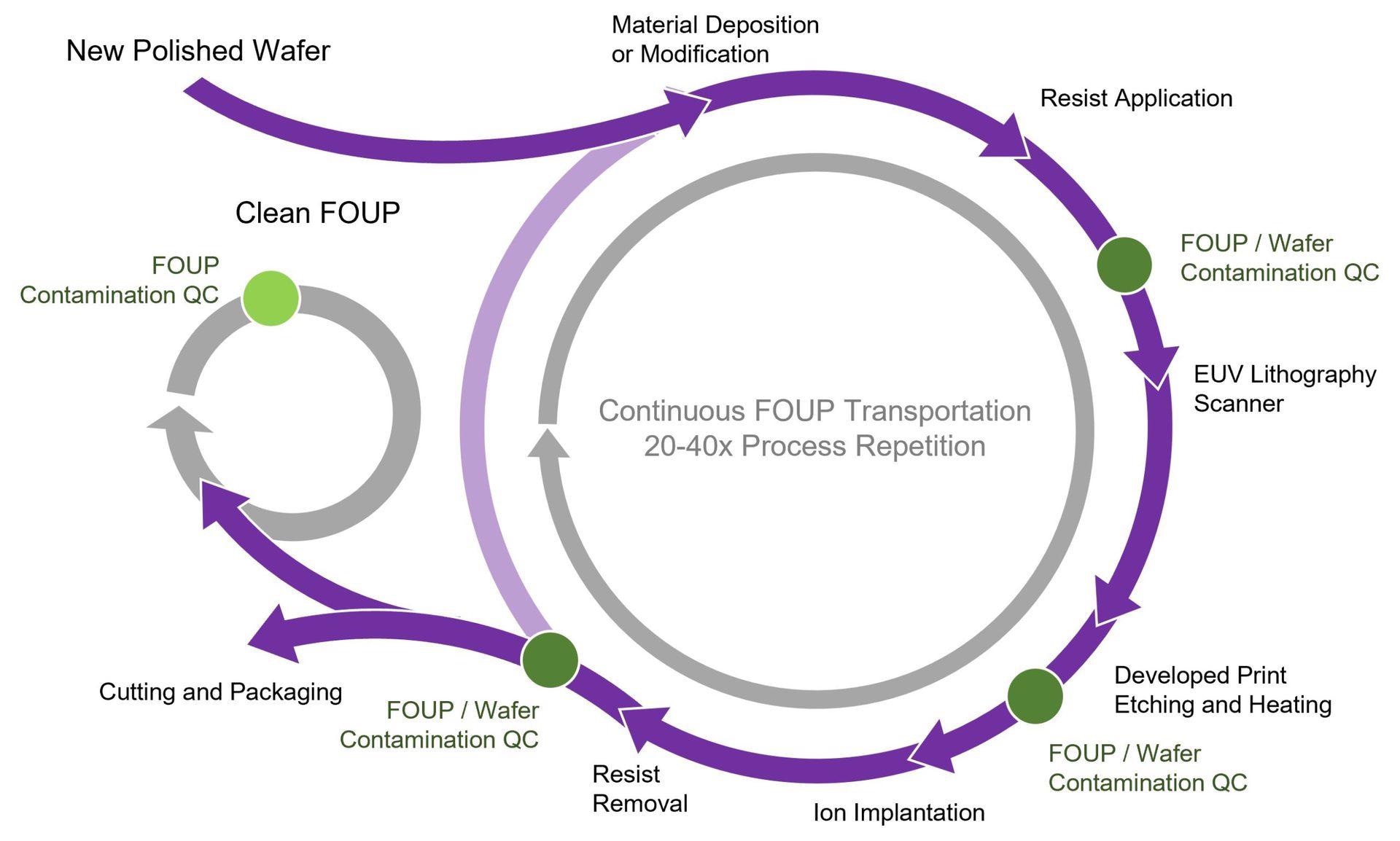

One of the most common outgassing sources in the fab environment are the front opening unified pods; known as FOUPs. FOUPs are used to transfer wafers from one process to the next to reduce contamination risk. It has been shown by studies that cross contamination can occur when outgassed AMCs from contaminated wafers remain in a FOUP. This then contaminates the next batch of clean wafers2,3. The greatest potential for cross contamination is presented by wafer transport by FOUP between the many areas of a fab.

The Vocus CI-TOF was used to perform replications for both MA and MB FOUP. Trace levels of AMCs were observed after more than 10 hours of continuous flushing in both instances, which demonstrates the long residence time of some compounds and the importance of their traceability.

Image Credit: TOFWERK

Fast, high-precision FOUP screening is demonstrated by the results from this simulation using the robust Vocus CI-TOF technology. Precise detection of trace AMCs is provided by the integration of the Vocus CI-TOF in FOUP-by-FOUP or batch wafer processing. Semiconductor producers will benefit significantly from this development: both from improved production yields but also reduced queue times, which can be attributed to rapid analysis with the Vocus CI-TOF.

An innovative and robust real-time analyzer, the Vocus CI-TOF is a vital component of any fab pursuing optimal performance. The Vocus CI-TOF uses industry-leading sensitivity and minimal operational overheads to offer comprehensive detection for a diversity of AMC categories. The utility of the Vocus CI-TOF has benefits for producers both real-time troubleshooting and retrospect evaluation.

Acknowledgments

Produced from materials originally authored by Carla Frege, Felipe Lopez-Hilfiker, Ben Bensaoula, Liang Zhu from

TOFWERK, Switzerland.

References

- Den et al. 2020. Doi: 10.1149/2162-8777/aba080

- Nguyen et al. 2013. Doi.org/10.1016/j.mee.2012.04.008

- Jeong et al. 2019. Doi. 10.1109/ASMC.2019.8791794

- Den et.al. 2006. Doi 10.1149/1.2147286

This information has been sourced, reviewed and adapted from materials provided by TOFWERK.

For more information on this source, please visit TOFWERK.