Sponsored by Element SixReviewed by Emily MageeNov 4 2022

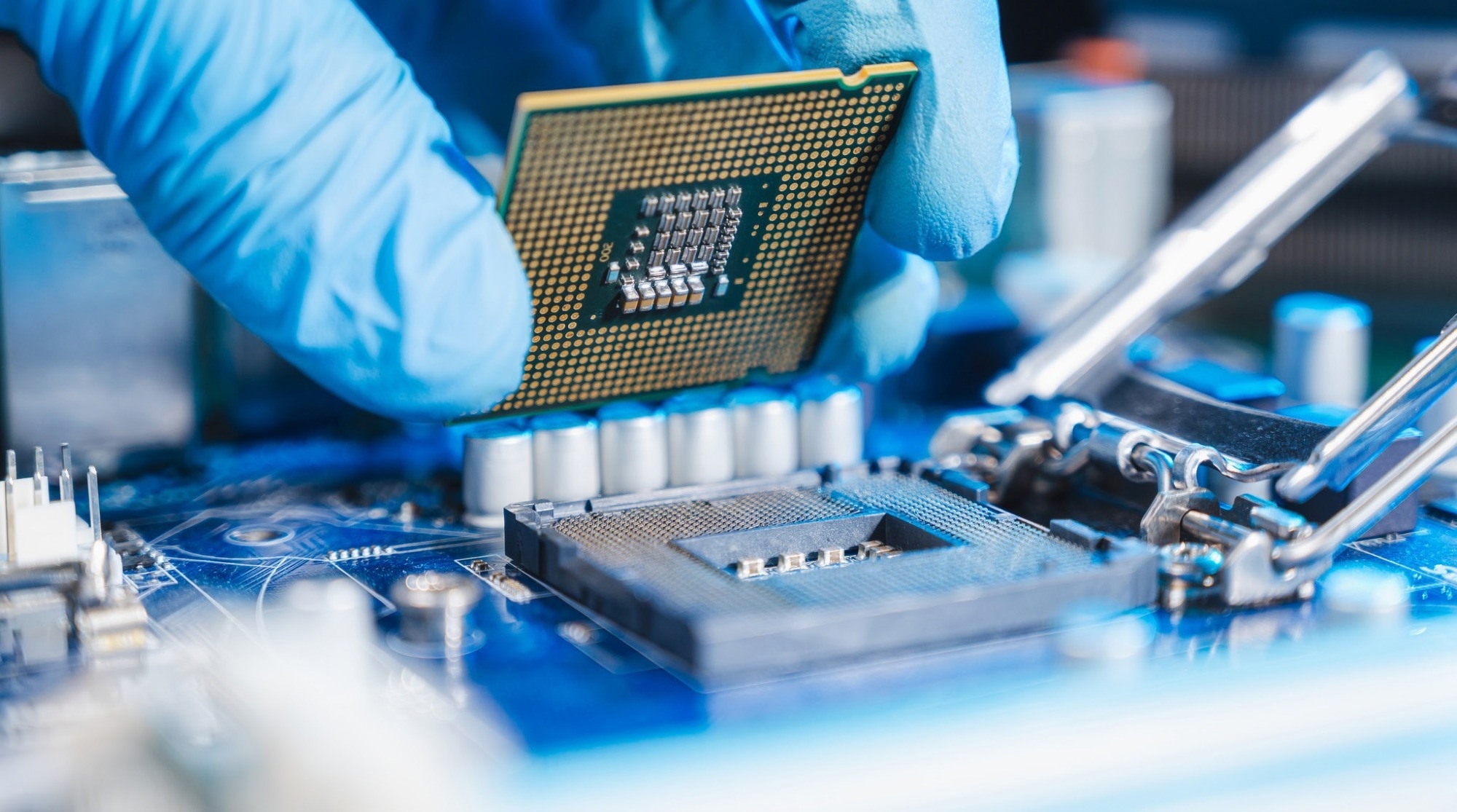

Progress toward revealing highly effective heat management solutions for semiconductors using diamonds is accelerating, thanks to a long-standing research partnership between the University of Bristol and Element Six.

For several decades, Element Six has had a successful working collaboration with the University of Bristol.

Image Credit: Element Six

To better comprehend the features of natural diamonds to artificially imitate them through the application of heat and pressure (HPHT) to graphite, De Beers established a covert project with the School of Physics in the 1950s, led by Sir Charles Frank. Sir Charles Frank is renowned for examining dislocations in diamond and contributing to many areas of solid-state physics.

Then, Andrew Lang, CBE, carried on with this work. The new chemical vapor deposition (CVD) method, pioneered by Element Six, was first supported by a collaboration with Professor Mike Ashfield in the late 1990s. This method is now opening up new opportunities in several applications, from high power density electronics to water treatment and quantum devices.

Element Six is now working with Martin Kuball, a professor of physics at the University of Bristol, to explore new avenues for characterizing and using diamond’s thermal conductivity.

Kuball’s research as the director of the Centre for Device Thermography and Reliability (CDTR) concentrates on the thermal management of electronics systems, especially the interface of diamond with semiconductor materials like gallium nitride (GaN) and gallium oxide (Ga2O3).

The partnership has resulted in the creation and improvement of CVD diamond thermal solutions, enabling the ever-increasing power density necessary to satisfy the tremendous demand for new technologies. High-bandwidth video calls, download and streaming services for many media types, and data transmission from CubeSats are a few examples.

The Challenge

Every electronics sector has seen a steady trend toward greater power density—the desire for more from smaller. While faster battery charging in electric vehicles asks for better power densities, the demand for low-cost data for video chats and streaming services necessitates larger bandwidth in base stations and satellites.

For efficient and dependable operation at power densities above a few kW/cm2, semiconductors require innovative thermal management technologies.

Around 50% of all electronic system failures are attributed to temperature, and a semiconductor device’s efficiency and junction temperature are directly correlated. Around 2–3 W of energy must be consumed for active cooling for every watt of energy lost in heat, which often increases system weight, size, and cost.

A high-powered radio frequency (RF) base station typically loses between 30 and 40% of its energy through heat. The efficiency of silicon power electronics, frequently used in automobiles, homes, and electric grids, can reach as high as 94%, but any improvement in performance above this point is extremely beneficial.

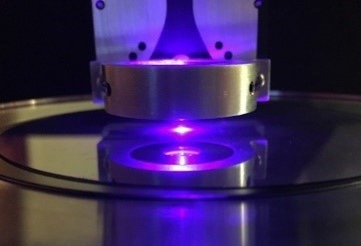

Optical based characterization of diamond materials using transient thermoreflectance (TTR). Image Credit: Element Six

Wide bandgap semiconductors have enabled the next generation of wireless architecture (5G and beyond), which has enhanced data communication speeds significantly above the present 4G.

Image Credit: Element Six

The Opportunity

With its exceptionally low density, high strength, radiation hardness, and high thermal conductivity (>2000 W/mK, more than five times higher than metals like copper and ten times better than ceramic equivalents), synthetic diamond offers game-changing heat dissipation.

The CDTR at The University of Bristol concentrates on thermal and thermo-mechanical modeling in electronics, locating and understanding the sources of heat loss in systems to improve thermal management.

According to the researchers, the loss can be measured and localized to a micrometer level using optical and Raman spectroscopy. Professor Kuball’s team can now use this information to integrate diamond thermal management with semiconductors primarily through the collaboration with Element Six and the University of Bristol’s experience in characterizing diamonds.

Element Six has assisted the University with R&D over the years, providing innovative materials, financing for PhDs and postdocs, funding for doctorate training, and cooperative involvement in EU, UK, and US DARPA development programs.

A University of Bristol spin-off firm, TherMap Solutions, offers rapid and simple data collecting solutions to examine thermal management for semiconductor materials, devices, and their packaging. In 2019, Element Six assisted Professor Kuball in establishing this company.

Thanks to a shared journey spanning over 50 years, Element Six and the University of Bristol have spent the last two decades leveraging mutual talent and expertise to better understand some of the fundamentals of plasma chemistry, helping the design of CVD diamond recipes. Today the market opening work with Kuball’s team is focused on understanding and applying the diamond developed through those recipes to deliver improved efficiency in the semiconductor industry.

Dr. Daniel Twitchen, Chief Technologist, Element Six

The Solution

Through this partnership with The University of Bristol, Element Six has enhanced its CVD diamond over the past ten years to produce wafers that can be sliced and processed to create sturdy, lightweight heat spreaders, resulting in lower operating temperatures and better performance.

Junction temperatures can be lowered by up to 40 °C with precise heat loss analysis, and device efficiencies can increase by 10% or more.

Diamond’s remarkable characteristics truly come into play in highly-powered electronics. Unlocking this potential has required a thorough understanding of making the contact between the semiconductor material and the diamond heat spreader as efficient as feasible at high power densities.

This is precisely where Professor Kuball’s experience as an applied physicist—including his trailblazing work on GaN laser diodes at Brown University—has been a huge asset.

Professor Kuball’s analysis made it possible to identify problems within the thermal barrier between the device wafer and diamond when Element Six originally pioneered the use of diamond for cooling GaN devices. The company could then greatly enhance its initial procedure.

At high power, thermal conductivity challenges increase significantly. What might work as a material solution in a lower powered device, such as a regular GaN laser diode, will not prove as effective in an RF device operating at extremely high voltage or, in the case of satellites, in extreme temperature cycles. This performance also needs to be sustained over time.

Martin Kuball, Professor, University of Bristol

The US defense industry has benefited significantly from this collaboration between academic and industrial researchers. Using diamond to address issues in high-powered military RF radar and data applications, Element Six and The University of Bristol have collaborated on several DARPA initiatives, including the Thermal Management Technologies program.

The use of electronics in Nano Satellites, or CubeSats, which are currently being investigated for Low Earth Orbit communication networks, is another area in which technological advancements demonstrate significant promise.

Thanks to the diamond’s dependability, effectiveness, and excellent radiation resistance, Element Six’s Diafilm™ TM220 offers the benefit of decreased weight and improved life for these small yet sophisticated devices.

Element Six’s Diafilm™ TM220. Image Credit: Element Six

To learn more, visit: www.e6cvd.com

Next Steps

According to Professor Kuball, diamond’s opportunity and challenge in the future will remain in its integration with other materials, such as silicon carbide (SiC), gallium oxide, and gallium nitride.

As part of a $22 million research funding program called the Chairs in Emerging Technologies, the Royal Academy of Engineering has awarded support to Professor Kuball, one of only eight UK academics to do so.

Kuball seeks to create a new class of semiconductor power electronic devices employing ultra-wide bandgap materials, including gallium oxide, boron nitride (BN), and aluminum nitride, for his project, “Ultrawide bandgap developing power electronics for a low carbon economy” (AIN).

These new gadgets will be small, incredibly adaptable, and, most importantly, more energy-efficient.

Although working with materials like gallium oxide poses many new hurdles, a super junction extremely effective when paired with diamond could be created to enable very high voltage electronics.

These challenges should be addressed through continual improvements in the characterization and optimization of the interface between new materials and diamond thermal management technologies, with continued knowledge exchange and assistance from Element Six.

Further research into diamond metal integration, which will lead to new advancements in the packaging of these semiconductor device technologies, is now funded by the EU’s Horizon 2020 program and is being conducted at the University of Bristol.

Recently, Element Six introduced its newest thermal grade, Diafilm™ TM220, offering the highest thermal performance and can be integrated into existing electronics through designed metallization and attachment schemes. This brings a step-change performance in lifetime and efficiency, resulting in a lower size and weight at a competitive cost.

Image Credit: Element Six

Image Credit: Element Six

Product Detail: Diafilm™ TM220

The world’s first diamond thermal solution, Diafilm™ TM220, was introduced in September 2019 and is designed to provide thermal conductivity of more than 2200 W/mK. Since TM220 is thermally isotropic, heat is distributed equally effectively through the material and in a planar direction.

Low dielectric permittivity, optical clarity, electrical insulation, low density, and chemical inertness are further characteristics that make it the ideal material for pushing the limits of advanced thermal management.

Further Reading

- New Diafilm TM220 from Element Six Offers Thermal Conductivity in Excess of 2200W/mK - 2019, Electronics Cooling

- CVD Diamond - Integrating a Superior Thermal Material-T Obeloer & B Bolliger, 2014, Electronics Cooling

This information has been sourced, reviewed and adapted from materials provided by Element Six.

For more information on this source, please visit Element Six.