Wet film thickness (WFT) is the measurement of the thickness of a paint or coating immediately after application before it undergoes drying. A Wet Film Thickness Gauge is utilized to gauge this thickness, providing a cost-effective, swift, and straightforward method.

Image Credit: Paul N. Gardner Company, Inc.

These gauges are applicable across a broad range of wet film thicknesses, accommodating both thick protective and thin coil coatings, and can be employed on virtually any substrate.

Wet Film Thickness Gauges, also recognized as Wet Mil Gauges, WFT Gauges, Combs, Comb Gauges, Mil Gauges, Step Gauges, and Notched Gauges, are specifically designed to swiftly and effortlessly assess paint and coating thickness post-application but before curing.

They integrate a set of notches resembling the teeth of a comb. A Wet Film Thickness Gauge facilitates easy wet film thickness measurement for uncured coatings, such as paints, roof coatings, powder coatings, intumescent coatings, gel coats, wood coatings, and more.

The measurement of wet coating thickness, or wet film thickness, is crucial for the applicator to ensure compliance with the manufacturer's specifications.

The repercussions of applying excessive coating include extended drying time, solvent entrapment, cracking, sagging, and increased material costs.

On the contrary, applying insufficient thickness may necessitate additional coats, leading to premature coating failure, inadequate hiding, undesirable appearance, and various issues that can result in extended job completion times, potential claims against the applicator, and diminished profits.

Applicators should promptly measure wet film thickness right after applying the coating, before significant solvent evaporation, to ensure accurate measurements.

Delays, even slight ones, could lead to erroneously low readings due to solvent evaporation before measurements are taken.

Throughout the application process, multiple readings are advisable to verify consistent wet film thickness across all coated surfaces. Therefore, applicators primarily utilize WFT gauges rather than inspectors. Frequent monitoring of wet coating thickness is essential to uphold a consistent coating process in line with manufacturers' specifications.

This practice aids in controlling coating costs and application time, enhancing overall efficiency and profitability for the applicator.

Adjustments to spray gun speed, the number of passes, and spray tips can be made to achieve the desired coating amount, meeting specified wet film thickness and, ultimately, the specified dry film thickness, which can be gauged using a dry film thickness gauge.

Approximate dry film thickness can be predicted by measuring wet film thickness. The calculation involves using the solids-to-liquids ratio. For instance, in a coating with 80% solids and 20% liquid, as the coating dries, the liquid evaporates, leaving only the solids in the dry film.

If the wet film thickness is 100 µm, the dry film thickness will be 80 µm (100 µm x 80% = 80 µm). Dry film thickness (DFT) is the thickness after complete liquid evaporation, expressed as DFT = WFT x % solids. Conversely, the equation can be reversed to measure the applied WFT based on the DFT.

How to use a Wet Film Thickness Gauge

Video Credit: Paul N. Gardner Company, Inc.

How to Use

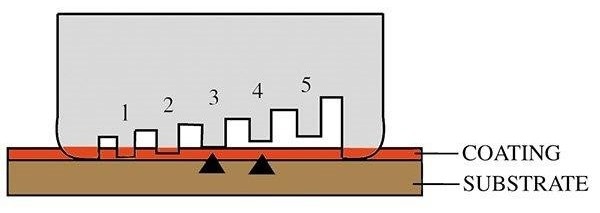

Using Wet Film Thickness Gauges is a straightforward process. These gauges feature notches (also called teeth) on their sides, aligned as references. The two outer notches, of equal size, rest on the substrate, serving as a zero reference.

The remaining notches on the same side are shorter and gauge the depth of the wet coating and its distance from the zero reference. These distances, measured in mils (0.001") or microns, signify the distance from the substrate surface. Below is a simple guide on how to use these gauges:

- Position the gauge on the wet coating at a 90° angle, perpendicular to the substrate

- Gently press it into the coating until contact is made with the substrate

- Withdraw the gauge and identify the deepest tooth with coating and the adjacent uncoated tooth

- The wet film thickness is between these two readings

- Immediately clean the gauge with a suitable solvent and dry it after use, or dispose of it properly

In the accompanying image, the gauge tooth labeled 3 mils has touched the wet coating, while the adjacent tooth marked 4 mils has not. This indicates a wet film thickness measurement between 3 and 4 mils.

Image Credit: Paul N. Gardner Company, Inc.

When measuring powder coatings, drag the gauge through the uncured powder coating to ensure adhesion to the gauge teeth. To summarize, Wet Film Thickness Gauges are:

- User-friendly

- Cost-effective tools for coating manufacturers and applicators to prevent claims arising from incorrect coating thickness application

- Economical enough to be disposable

- Customizable at a minimal cost

- Integral for achieving high-quality coating applications

Comply with the requirements of the following International Standards: ASTM D4414, ISO 2808-7B, BS 3900-C5 Method 7B, NF T30-125, NASI/NCSL Z540-1

This information has been sourced, reviewed and adapted from materials provided by Paul N. Gardner Company, Inc.

For more information on this source, please visit Paul N. Gardner Company, Inc.