To begin, could you briefly explain what Fiber-Reinforced Polymer (FRP) composites are, and why their visual quality is often tied so closely to structural expectations in end-use applications?

Fiber-Reinforced Polymer (FRP) composites are engineered materials composed of a polymer matrix reinforced with fibers – most commonly glass or carbon. These materials offer a high strength-to-weight ratio, corrosion resistance, and design flexibility, making them suitable for everything from pedestrian bridges to chemical plant structures.

FRP can be manufactured using a variety of manufacturing methods. For our discussion today, I’ll focus on FRP manufactured using the pultrusion process, as it is the most common method for manufacturing structural parts and the basis for ASTM D4385, Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products, which is a key resource for structural engineers and field inspectors.

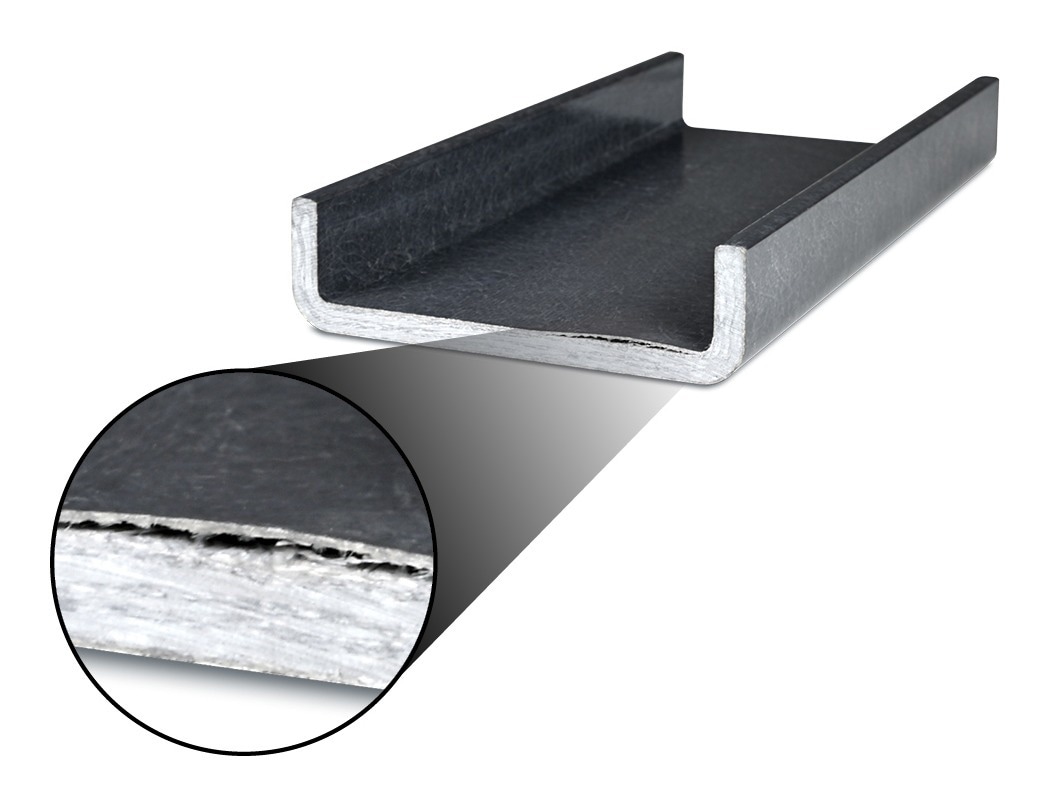

Strongwell pultruded FRP. Image Credit: Strongwell Corporation

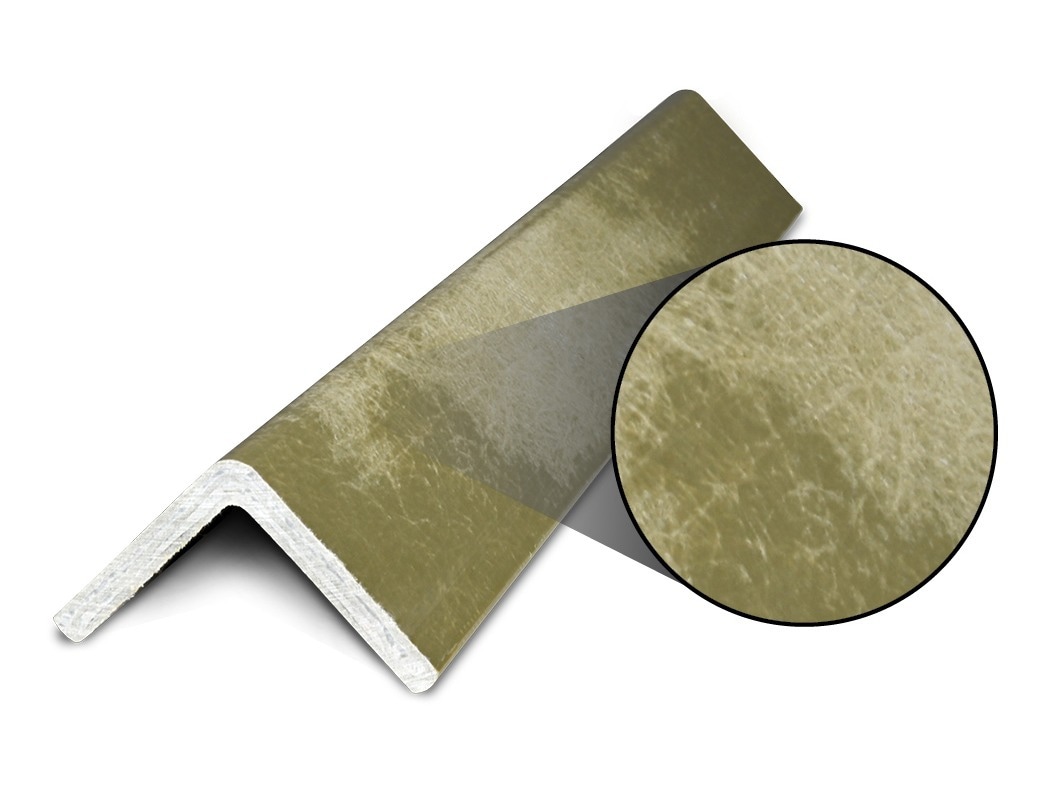

Strongwell pultruded FRP. Image Credit: Strongwell Corporation

In end-use applications, visual appearance often serves as a first line of defense when considering structural quality. Engineers and inspectors intuitively associate a smooth, uniform surface with proper wet-out, fiber alignment, and resin distribution. When a part looks flawed, it can often indicate inconsistencies in the manufacturing process that may affect load-bearing capacity or long-term durability.

Your recent flyer highlights three specific visual defects—resin-starved areas, dry fibers, and delaminations—as indicators of compromised structural integrity. Can you walk us through how each of these defects forms during production?

While many defects can compromise structural performance, we recently highlighted three recurring issues we frequently encounter in substandard material – especially from less experienced pultruders. These problems often show up in the field and are all tied to poor manufacturing practices. Here's a closer look at each one:

- Delamination: This occurs when the reinforcing fibers are not fully saturated with resin. It's typically caused by improper heat settings, inadequate wet-out of the fibers, or poor resin chemistry. The result is separation within the layers, which can significantly weaken structural integrity.

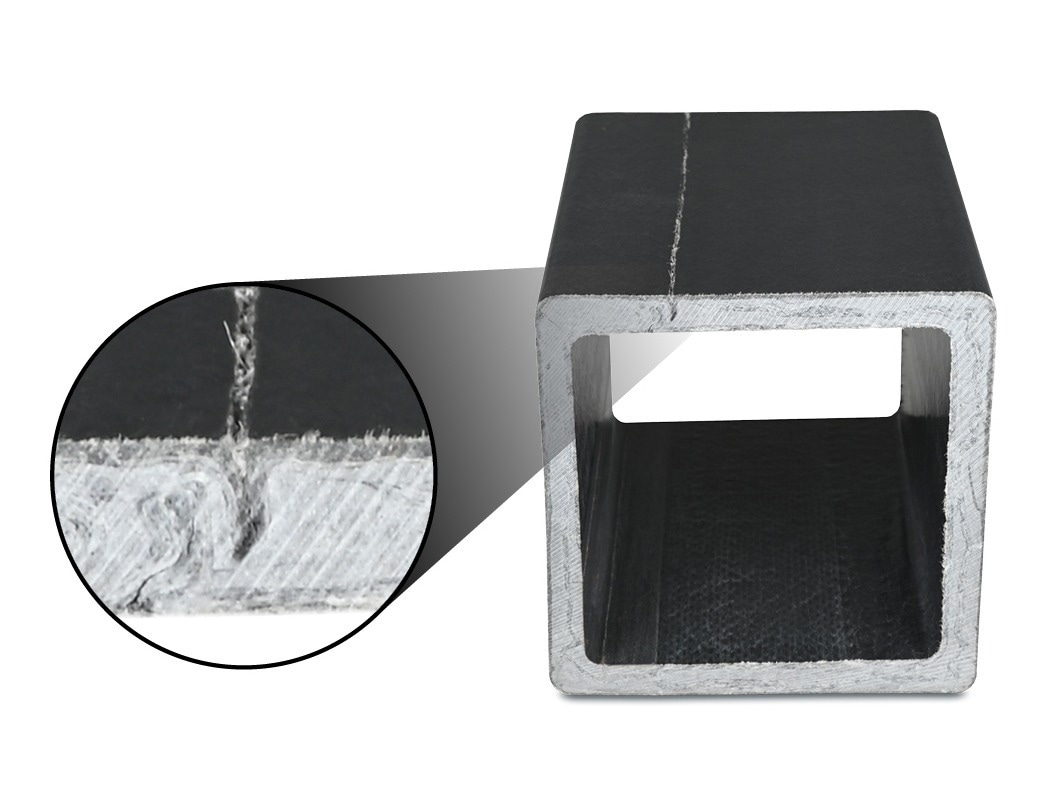

A close-up of visual defects with delamination. Image Credit: Strongwell Corporation

- Discoloration Caused by Under-Curing: Under-cured parts often show visible discoloration and can indicate that the manufacturing process was rushed or conducted at too low a temperature. It may also stem from an incorrect resin mix ratio. These parts haven’t fully cured, which compromises both their appearance and performance.

A close-up of visual defects with discoloration. Image Credit: Strongwell Corporation

- Cracks: Cracks formed during manufacturing usually result from excessive pressure as the material is pulled through the die or from improper reinforcement layout. These stress points can lead to early failure under load or over time.

A close-up of visual defects with cracks visible. Image Credit: Strongwell Corporation

Why are these defects particularly dangerous in field applications? Are there specific failure modes or structural risks associated with each one that engineers should be aware of?

An “ugly” FRP part is more than just a cosmetic issue – it’s often a red flag for serious structural concerns.

Delamination significantly reduces a part’s load-bearing capacity. In critical applications like columns or beams, this can lead to premature buckling or even structural failure.

Under-cured parts are equally problematic. They may warp or degrade inconsistently over time, especially when exposed to heat or repeated load cycles, making long-term performance unpredictable.

Cracks compromise reliability by creating localized stress concentrations that tend to grow under fatigue. These failures often occur without warning.

The bottom line: visible defects are warning signs that shouldn't be ignored. You can't reliably predict how much performance has been lost, and there's no easy way to test for it after the fact. If a part looks compromised, it probably is.

The flyer makes reference to ASTM D4385. How does this standard serve as a reference point for evaluating visual defects, and what role does it play in quality assurance for FRP manufacturers?

ASTM D4385 provides terminology and visual inspection guidance for pultruded FRP. It defines acceptability criteria based on a defect that could lead to a structural failure or not.

For manufacturers like Strongwell, D4385 supports a broader Quality Assurance (QA) program, helping to ensure consistency in how visual cues are interpreted during inspections. For inspectors, it helps to offer consistent guidance on areas of concern in performance vs. those that are simply aesthetic.

In practice, how often are visual inspections alone sufficient to catch these defects before installation? Are there nondestructive evaluation methods or emerging technologies that can assist manufacturers or inspectors in identifying deeper structural issues?

Visual inspections are sufficient as a first line of defense. However, to further check parts for defects such as delaminations, cracks, or improper wet-out, a quick tap test is widely used. With this method, a change in sound indicates a non-destructive defect. Other methods, such as ultrasound or infrared detection, are also used in some instances.

Most manufacturers periodically perform simple deflection tests to validate their manufacturing standards, and customers can request certificates of conformance or test data as part of their order requirements. Once parts are received in the field, installers should be familiar with what a good part looks like and keep an eye out for any anomalies. While both basic and advanced inspection tools are available, these are typically only used when a visual defect warrants deeper investigation.

Simple deflection test. Image Credit: Strongwell Corporation

Simple deflection test. Image Credit: Strongwell Corporation

From your perspective, why do these defects still find their way into the field, especially from lower-cost suppliers? Is this more often due to manufacturing oversight, cost-cutting, or misinterpretation of quality standards?

Strongwell’s reputation in the industry is built, at least in part, on our rigorous quality standards. Every part we produce goes through first article inspection and ongoing testing to ensure consistency and performance. Our ISO 9001 certification reflects the strict processes, quality checks, and audit requirements we follow throughout manufacturing.

Unfortunately, not all manufacturers operate at the same level. In some cases, a lack of properly trained personnel – or a poor understanding of resin chemistry, processing techniques, or quality standards – leads to inconsistent and subpar production. This is a key reason we continue to see substandard pultruded parts entering the market.

What are the long-term consequences, both structural and financial, when these types of visual defects go unnoticed until after installation in major infrastructure projects?

Structurally, hidden weaknesses like delaminations or cracks can lead to failure under normal loads – and in some cases, catastrophic collapse. Financially, the costs of repairs, replacements, legal claims, and project delays can quickly outweigh any short-term savings from choosing an inferior supplier. Reputationally, trust is lost – not only in the manufacturer but also in the installer who approved the flawed material.

These are just a few of the reasons why Strongwell remains deeply involved in shaping industry-wide test standards, protocols, and procedures. As the recognized global leader in pultrusion and pultruded FRP, we’re committed to ensuring that no substandard parts, regardless of the manufacturer, make it into the field.

Looking at the industry more broadly, what role do you see education and outreach campaigns like “When Visual Defects Mean Structural Risk” playing in shifting perceptions around FRP inspection and quality control?

Generally speaking, pultruded FRP has earned a strong reputation as a reliable alternative to steel, aluminum, wood, or concrete across a wide range of applications. In traditional construction, materials like these are subject to quality reviews by on-site inspectors and are expected to meet the performance standards defined by the engineer during the design phase. FRP should be held to that same level of scrutiny – and any material that doesn't meet the standard should be rejected.

At Strongwell, we’re committed to reinforcing the importance of proactive quality control and continuing to push for consistent, industry-wide standards that protect both performance and trust.

Given your experience, how can specifiers, engineers, and procurement teams better protect themselves from accepting FRP components with high structural risk hidden behind visual imperfections?

To avoid costly surprises, specifiers, engineers, and procurement teams need to look beyond price when selecting FRP materials. This may involve specifying minimum mechanical properties and acceptable visual appearance, referencing standards like ASTM D4385, and requiring that all delivered parts comply. It could also mean auditing a manufacturer’s quality assurance processes or requesting third-party documentation of their quality standards.

Our goal is to raise awareness that not all FRP is created equal—and to encourage buyers to make more informed, standards-driven decisions.

Do you foresee any changes or tightening of standards like ASTM D4385 in the near future, as more attention is drawn to the structural implications of visual defects in FRP products?

I believe the current standards for visual defects are well-designed and effective. What’s really needed is greater awareness and consistent compliance with those standards across all FRP manufacturers – and for customers to actively demand that compliance.

About Bhyrav Mutnuri

Bhyrav Mutnuri is the Director of Research and Development at Strongwell, overseeing all of the company’s R&D initiatives. His work spans new product development, quality assurance, and testing.

Mutnuri holds a Bachelor of Technology in Mechanical Engineering from Jawaharlal Nehru Technological University and a Master of Science in Mechanical Engineering from West Virginia University. He brings extensive experience in the composites industry, with a focus on pultrusion manufacturing, mechanical testing, and material characterization.

He is also an active member of several industry and standards committees, contributing to the advancement of best practices within the composites field. Mutnuri is based at Strongwell’s corporate headquarters in Bristol, Virginia.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.