The lithium-ion battery (LiB) industry is projected to grow as countries transition to electric vehicles to achieve carbon neutrality, alongside increasing demand for devices such as smartphones and tablets. The technology used for coating current collectors significantly influences battery performance during LiB manufacturing.

Image Credit: Alexander56891/Shutterstock.com

When producing LiB electrodes, active materials are mixed with binders and solvents, then applied to current collectors, dried, and compressed to enhance packing density. Thicker coatings generally boost battery capacity but may hinder rate characteristics, while thinner coatings enhance rate performance but decrease overall capacity.

To improve the volumetric energy density of LiBs, it is essential to enhance the filling properties of positive and negative electrode materials and to elevate electrode density.

Assessing the density of these electrode materials is essential for enhancing battery features and achieving optimal performance. To meet manufacturing process requirements, density measurements must continuously track changes in powder samples from low to high pressures.

This article demonstrates the evaluation of the bulk density of graphite powder, utilized as an anode material, using the AGX-V2 precision universal testing apparatus.

Test Configuration

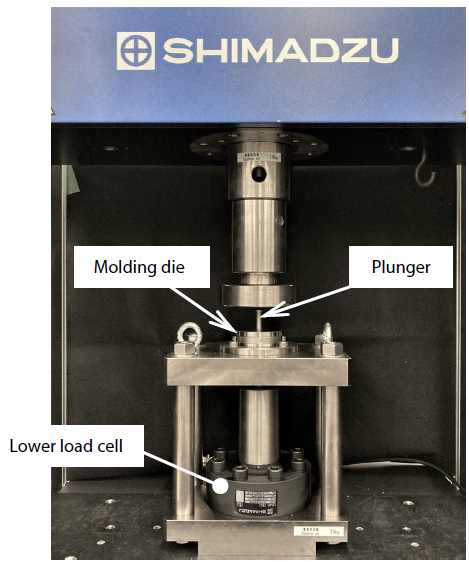

Table 1 outlines the conditions for testing conducted with the AGX-V2 precision universal testing apparatus featuring a powder-forming device.

In powder compression testing, the applied force is distributed to the inner walls of the die. To manage this, the test force is monitored at the upper and lower sections. The total applied force is calculated from the average readings of the upper and lower load cells. Even if the mass of the powder and the applied force are equivalent, variations in die diameter can lead to differing pressure distributions on the walls, potentially affecting test outcomes.

The testing involved samples weighing 1 g, utilizing a 1/2 inch diameter molding die, with a maximum force of 50 kN applied to the upper load cell.

Table 1. Test Configuration and Test Conditions Using the Precision Universal Testing Machine. Source: Shimadzu Scientific Instruments

| . |

. |

| Testing Machine |

AGX-100kNV2 |

| Upper Load Cell |

100 kN |

| Lower Load Cell |

100 kN |

| Test Jig |

Powder forming test device (molding die diameter 1/2 inch) |

| Software |

TRAPEZIUMX™-V (single) |

| Test Speed |

5 mm/min |

| Target Value |

Up to a test force of 50 kN in the upper load cell |

| Sample |

Four types of graphite powder (A, B, C, and D) with different particle sizes |

| Sample Mass |

Weighed to 1 g ± 0.005 g |

Fig. 2 illustrates the test setup. The TRAPEZIUMX-V's deflection correction feature was used to adjust measurements for any deformation occurring in the jig and load cell during crosshead movement.

Fig. 1. Precision Universal Testing Machine AGX™-V2. Image Credit: Shimadzu Scientific Instruments

Fig. 2. View of a Test. Image Credit: Shimadzu Scientific Instruments

Test Results

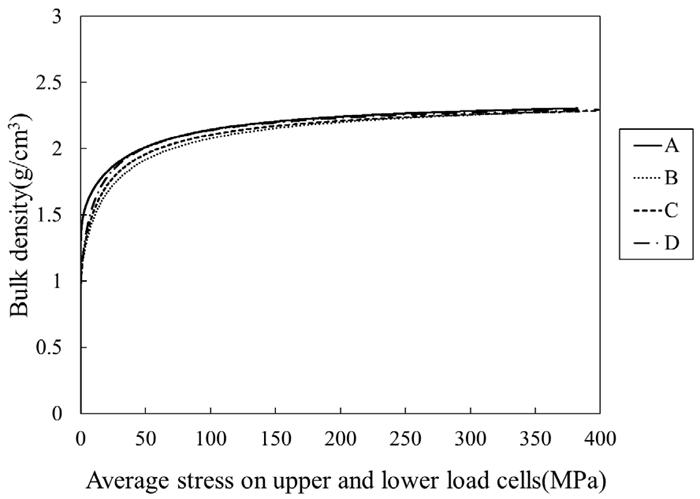

Fig. 3 presents the findings from the tests. It was noted that all samples achieved a bulk density of approximately 2.3 g/cm³ when the average stress of the upper and lower load cells was around 350 MPa.

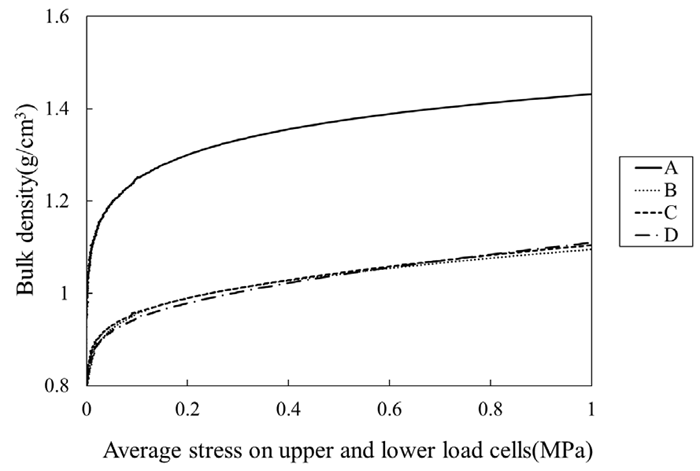

Fig. 4 displays the stress curves up to 1 MPa. Samples B, C, and D showed similar behaviors, while sample A demonstrated distinct characteristics.

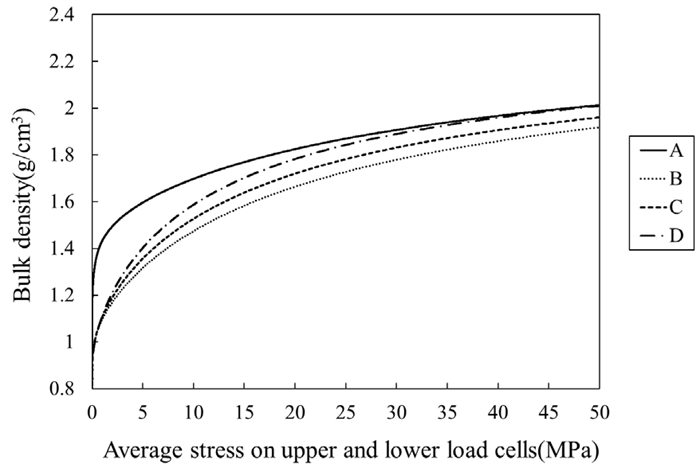

Fig. 5 illustrates the stress curves up to 50 MPa. At this load, the bulk densities were ranked as A = D > C > B.

Fig. 3. Test Results. Image Credit: Shimadzu Scientific Instruments

Fig. 4. Test Results (Curves up to 1 MPa). Image Credit: Shimadzu Scientific Instruments

Fig. 5. Test Results (Curves up to 50 MPa). Image Credit: Shimadzu Scientific Instruments

Conclusion

Utilizing the AGX-100kNV2, bulk density measurements were performed for four types of graphite powders with varying particle sizes. Each sample exhibited unique behavior based on the applied force. However, all samples displayed similar characteristics under high forces, reaching bulk densities close to 2.3 g/cm³.

The AGX-V2 facilitates bulk density measurements across a broad range of forces. This capability is expected to significantly improve battery performance, particularly in enhancing energy density.

Acknowledgments

Shimadzu would like to express its deep gratitude to Dainen Material Co., Ltd., for providing the samples.

This information has been sourced, reviewed and adapted from materials provided by Shimadzu Scientific Instruments.

For more information on this source, please visit Shimadzu Scientific Instruments.