In this interview, AZoMaterials speaks with Dr. Stuart Robertson, Senior Electron Microscopist at the Materials Characterization Centre, about how plasma FIB technology is enhancing research into photovoltaic materials and cathodoluminescence imaging.

Can you please introduce yourself and your role at the Materials Characterization Centre?

My name is Dr. Stuart Robertson, and I’m a Senior Electron Microscopist at the Materials Characterization Centre. We're a multi-user facility that works across a wide range of disciplines, from sports science to photonics.

One of our main research focuses is currently on photovoltaic materials, especially cadmium telluride solar cells. We also host a national facility for high-resolution cathodoluminescence, where we’re combining plasma FIB and TEM capabilities to enable cutting-edge characterization.

Image Credit: Shutterstock.com/MAXSHOT.PL

What drove your team to invest in a plasma FIB system, and how has it impacted your research?

Initially, the PFIB was brought in for large-area steel analysis. As interest in photovoltaic materials grew, we started using the system for that as well. One of the biggest advantages has been the ability to collect large-area datasets, giving us much more statistically significant results than conventional 20-micron samples.

Also, plasma FIBs produce much lower ion beam damage than traditional gallium systems, which has been crucial for speeding up cathodoluminescence analysis. In many cases, it’s the only practical way for us to prepare certain samples.

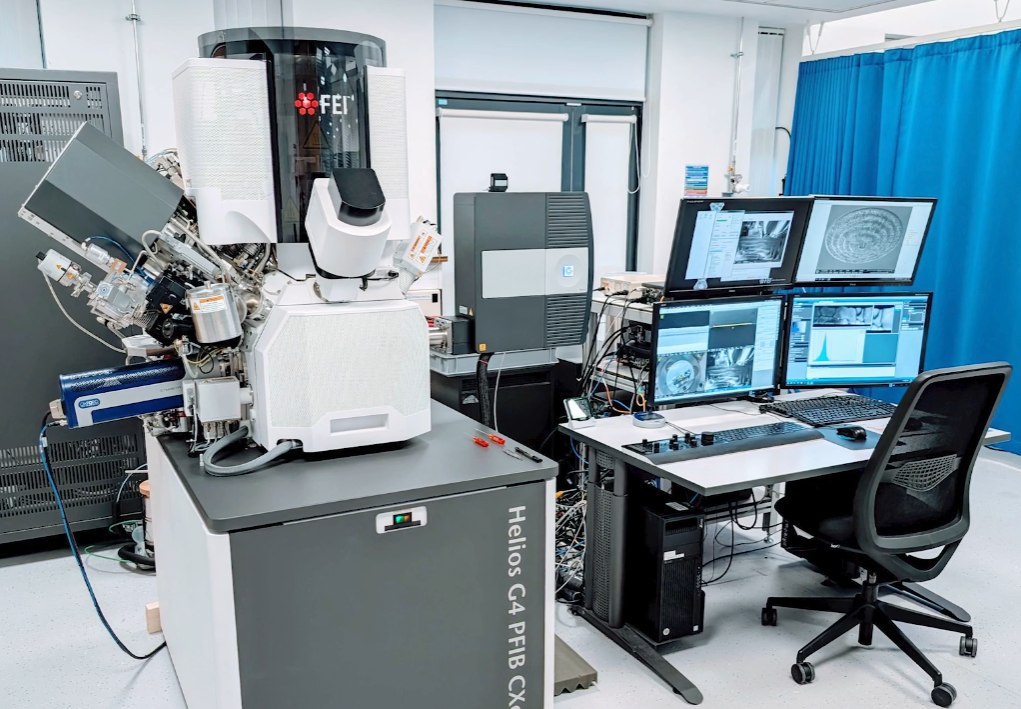

Thermo Scientific's Helios PFIB System at the Loughborough Materials Characterization Centre. Image Credit: Dr. Stuart Robertson

You work with a wide range of materials. How does the plasma FIB accommodate that variety?

The key benefit for us is the ability to cut large volumes of material. That’s really important when you want to correlate data from different modalities, like optical microscopy or micro-CT. The PFIB allows us to remove significant sections of material and then pinpoint features of interest. That flexibility has enabled correlative workflows we couldn’t achieve before.

Despite using a previous-generation system (the Helios G4), your team seems quite satisfied. Why is that?

Although it’s a slightly older model and only runs a single gas (xenon), it still performs very well for many materials. Xenon is actually quite effective for a broad range of applications.

Beyond that, the scripting capabilities have been extremely helpful. We’ve used them to automate in-situ thermal heating experiments, capturing aligned image sets and stitching data together automatically. That would’ve been a very manual, time-consuming process before. So even though it’s not the latest generation, the system still enables complex experiments with ease.

Have there been any recent projects where the plasma FIB made a unique impact?

Yes, our cathodoluminescence work has really benefited. The low-damage preparation enabled by the xenon ion beam means we can acquire datasets much faster and with better signal integrity. This applies to both SEM-based CL and to preparing high-quality TEM specimens. The improved efficiency has made a big difference in how quickly we can produce publishable or usable data.

What trends or talks have caught your eye at MMC 2025?

I’ve been really impressed with the work people are doing on low-dose analysis of perovskite solar cells. That’s a technology we’re keen to explore further ourselves.

Another exciting area is the integration of TEM and SEM workflows - especially in-situ capabilities - which I think will open up a lot of new research opportunities. I also found the new EBSD detectors with direct electron detection from Thermo quite exciting.

How would you describe your collaboration with Thermo Fisher Scientific?

It’s been excellent. Configuring the FIB system with cathodoluminescence was quite a technical challenge, but Thermo supported us from specification through to installation and commissioning. We’re now working with them on sample applications to showcase what the system can do. Their support has really helped us push forward with new methods and collaborations.

What excites you most about the future of plasma FIB technology in your field?

What excites me is the potential to combine low-damage sample prep with more advanced, correlative imaging techniques. As materials get more complex, especially in photovoltaics and nanotechnology, the ability to analyze them comprehensively, without damaging them, becomes increasingly important. Plasma FIB is central to that capability. I’m looking forward to seeing more developments in automation and multi-modal workflows that will continue to expand what we can do with these systems.

About Dr. Stuart Robertson

Dr. Stuart Robertson is the Senior Electron Microscopist at the Materials Characterisation Centre, Loughborough University. He specializes in advanced electron microscopy techniques, with a focus on cathodoluminescence and FIB-based sample preparation. His expertise spans photovoltaic materials, nanostructured materials, and correlative imaging.

Dr. Robertson earned his Ph.D. in Physics from the University of Nottingham, where he developed a strong foundation in scanning probe microscopy and nanoscale materials characterization. At Loughborough, he leads efforts in expanding the use of plasma FIB and high-resolution CL for multidisciplinary research. He is also actively involved in national collaborations, advancing methodologies for low-damage analysis in emerging materials systems.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.