The Apreo ChemiSEM system delivers detailed characterization of Al-2024 alloys, offering efficient phase analysis and microstructural insights to optimize materials for aerospace, automotive, and battery applications.

Aluminum alloys, particularly AA2024, are widely used in aerospace and automotive for their strength and corrosion resistance. Understanding how the microstructure and composition of these metals change when subjected to different heat treatments is key for creating products with desired performance and longevity.

Thermo Scientific’s Apreo ChemiSEM system provides an all-in-one solution for comprehensive characterization, enabling the analysis of precipitates, dispersoid particles, and microstructural variations with unparalleled efficiency.1

Image Credit: Mario Hagen/Shutterstock.com

Problem: The Drive for More Effective Microstructural Analysis

Many high-performance industries demand lightweight materials with reliable strength and corrosion resistance. Al-2024 alloys, commonly used in structural components, truck wheels, gears, and aircraft parts, owe their enhanced properties to alloying elements like copper, magnesium, manganese, and iron.

These elements form various precipitates and intermetallic phases that change under different heat treatments, affecting the alloy's mechanical properties and performance.

Identifying and characterizing these microstructural variations offers deep insights into the product, yet traditional analysis methods are often time-consuming and less effective at capturing nanoscale details.1

Challenges: Dissecting the Limitation of Conventional Analysis Techniques

Traditional methods for analyzing Al-2024 alloys involve separate scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and electron backscatter diffraction (EBSD) techniques. These methods and the approach of using each individually carry specific constraints, including:

- Time-Consuming Process: Switching between different tools and workflows for imaging and chemical analysis is inefficient and prone to errors.

- Difficulty in Phase Identification: Identifying specific precipitates and the area fraction of each type is challenging using conventional EDS analysis, a technique sometimes regarded as less sensitive.1,2

- Nanoscale Characterization: Resolving and analyzing nanoscale features, such as dispersoids smaller than 25 nm, is difficult with SEM techniques used in isolation, often leading to incomplete data on material properties.3

For industries where precision and efficiency are vital, these challenges hinder the ability to make informed decisions regarding material selection, processing, and quality assurance.

Solution: Enter Apreo ChemiSEM – An Integrated Approach to Comprehensive Analysis

Thermo Scientific’s Apreo ChemiSEM system overcomes these challenges by combining high-resolution imaging with integrated chemical and structural analysis. For Al-2024 alloys, this means accurate and efficient characterization for a better understanding of microstructural changes. Apreo ChemiSEM addresses customer challenges through the following methods:

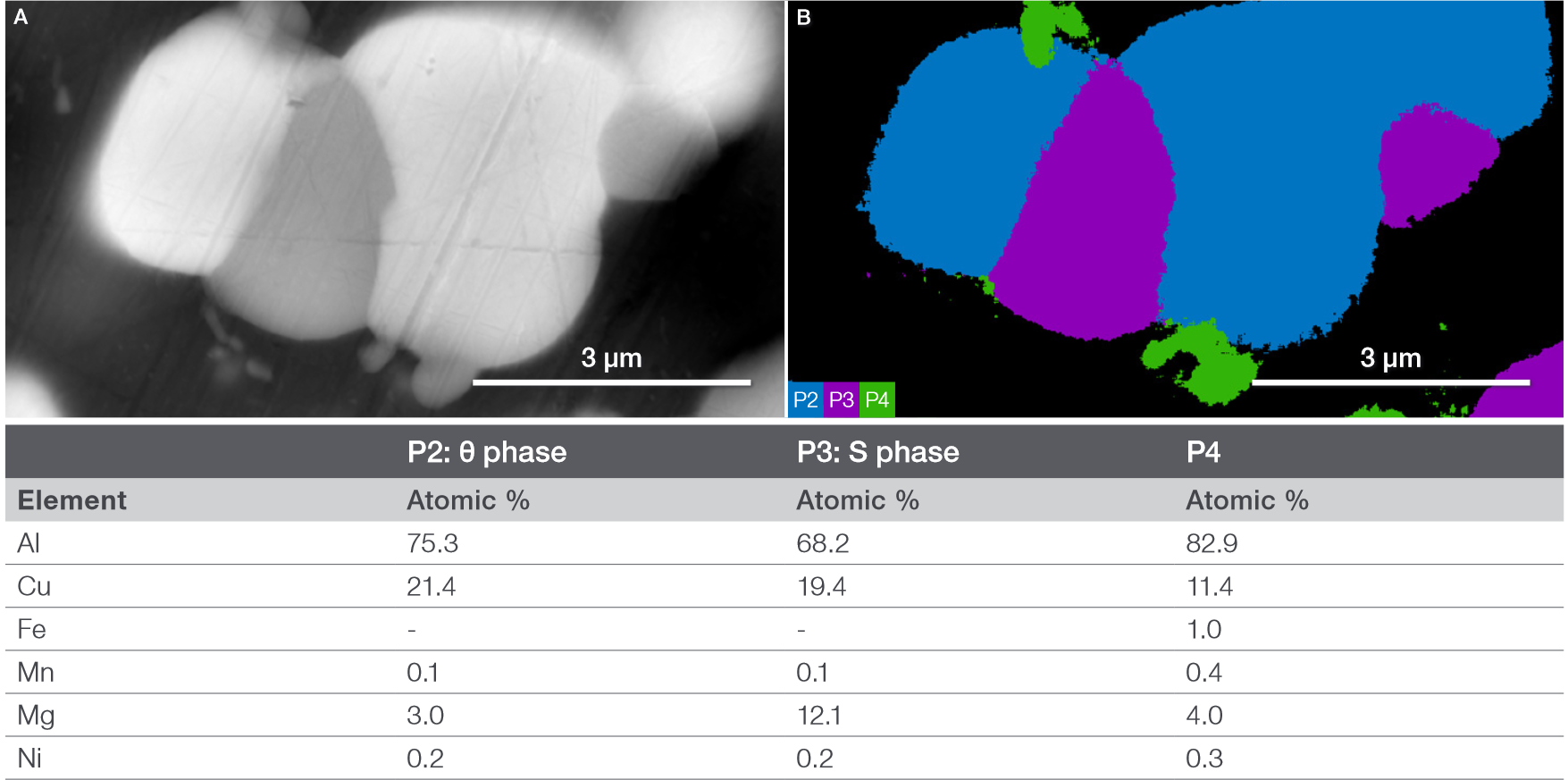

The Apreo ChemiSEM seamlessly combines imaging with elemental analysis through its innovative ChemiSEM Technology, which provides live quantitative mapping and phase identification. This integration allows for rapid and accurate analysis, helping users identify various precipitates and intermetallic particles in Al-2024 alloys.4

Its ChemiPhase functionality automates phase analysis, efficiently identifying all materials in the analyzed area.

Image Credit: Thermo Fisher Scientific

It recognizes all different phases, provides their spectrum, calculates their associated quantification, and determines the area fraction, providing a comprehensive understanding of possible compositional variations.1

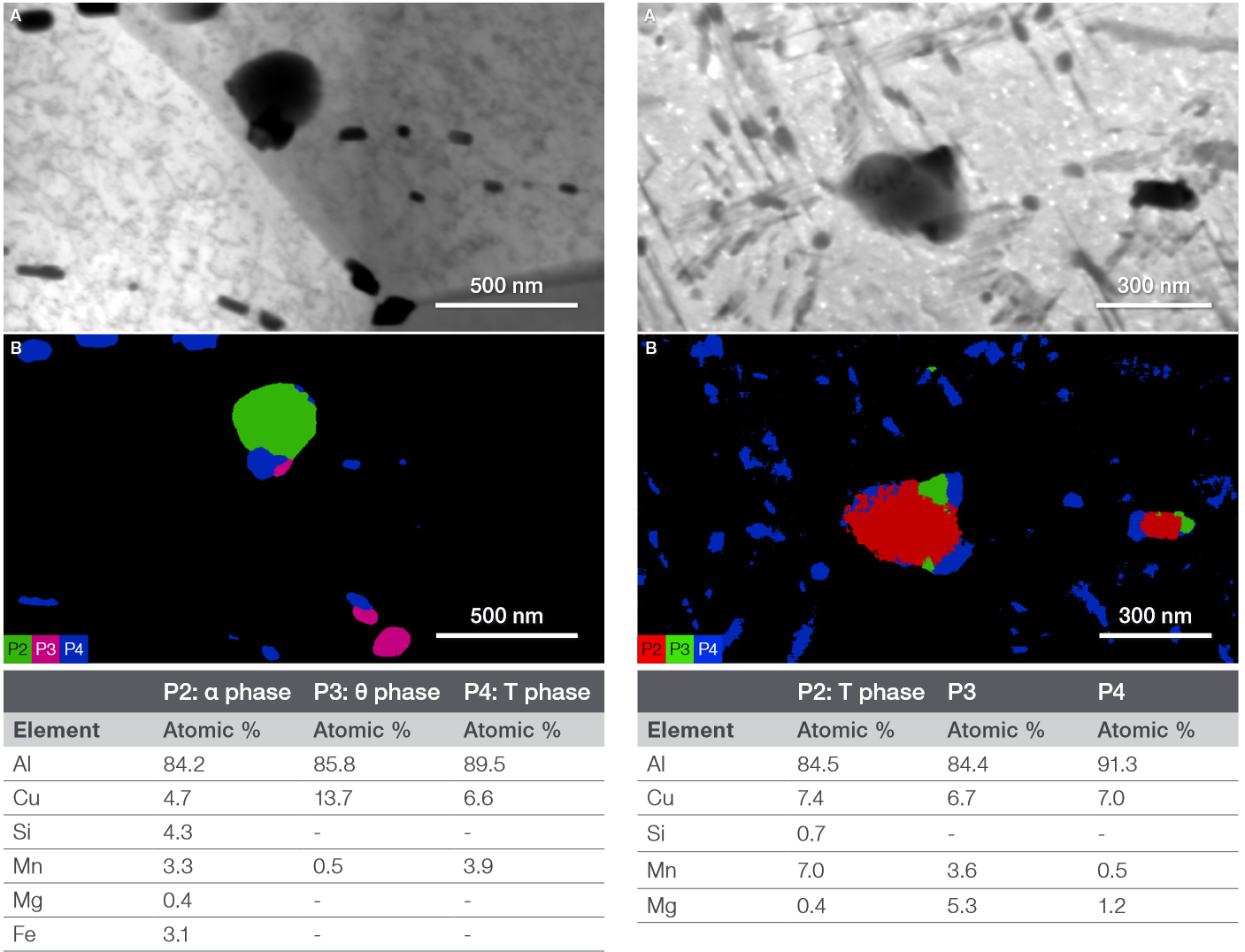

2. Advanced STEM-EDS for Nanoscale Characterization

The retractable STEM 3+ detector boosts nanoscale imaging capabilities, allowing users to analyze dispersoids and other features at the nanoscale. The STEM-EDS analysis provides detailed information on the type and distribution of particles.1

Image Credit: Thermo Fisher Scientific

In a recent study using the Apreo ChemiSEM, different types of precipitates and dispersoids, such as the θ-phase (Al2Cu) and S-phase (Al2CuMg), were identified across samples that underwent different heat treatments.

This information is key to understanding how heat treatments affect the alloy's microstructure, helping manufacturers improve their processes.1

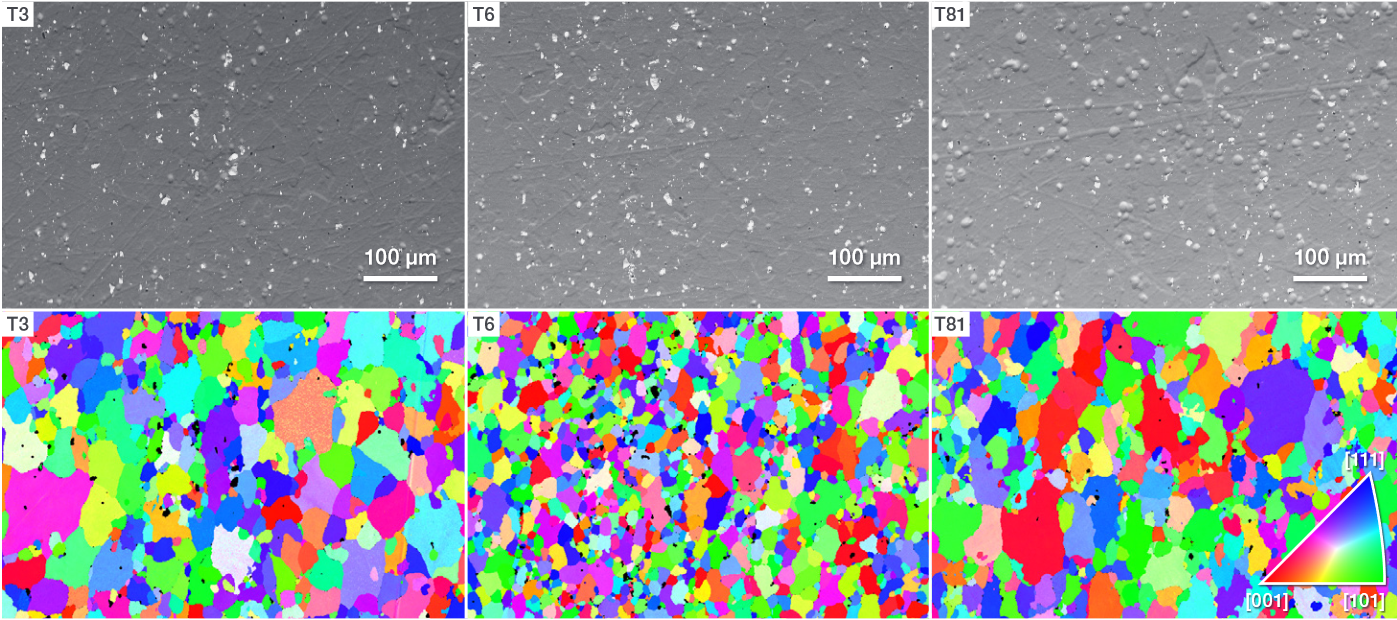

3. Electron Backscatter Diffraction (EBSD) with TruePix Detector

The Apreo ChemiSEM system's TruePix EBSD detector offers easy-to-access crystallographic information such as phase identification and distribution, grain sizes, orientation and boundaries, texture, and dislocations.

It allows scientists to correlate grain structure with EDS data, enhancing the understanding of how heat treatments influence the alloy’s microstructure. This feature is particularly valuable for optimizing heat treatment parameters in aerospace and automotive applications.1

For example, EBSD analysis on Al-2024 samples revealed significant grain size and orientation differences due to heat treatment variations.

Image Credit: Thermo Fisher Scientific

Samples that underwent heat treatment, cold rolling, and artificial aging exhibited large, relatively uniform grains. Samples that skipped the cold-rolling stage had smaller grains, influencing the alloy's mechanical properties.1

The Apreo ChemiSEM system is designed for multi-purpose labs, offering automated features like SFI, autofocus, and autostigmation.

These features eliminate manual alignments and augment imaging settings, making high-quality data accessible to all users, regardless of experience level. The system is always aligned and ready for imaging, ensuring efficient data collection with less hassles.4

Conclusion: Empowering Precision in Alloy Characterization for Industry Excellence

The Thermo Scientific Apreo ChemiSEM system offers a comprehensive solution for analyzing Al-2024 alloys. It enables efficient characterization of precipitates, dispersoid particles, and microstructural variations.

Integrating high-resolution imaging with advanced phase analysis, STEM-EDS, and EBSD capabilities provides a complete understanding of the effects of different heat treatments on alloy microstructure.

For aerospace, automotive, and battery manufacturing industries, where understanding material properties is crucial for product performance and safety, the Apreo ChemiSEM system stands out as a powerful tool.

It facilitates efficient, accurate analysis, providing a complete picture of the characterized materials and allowing users to optimize material selection, processing, and quality control.

Visit Thermo Fisher Scientific for more information on how the Apreo ChemiSEM system can benefit your research or production process.

References and Further Reading

- Scarpellini, Alice., et al. (2024). Comprehensive analysis of precipitates, dispersoids, and microstructure with SEM, STEM, EDS, and EBSD. Thermo Fisher Scientific. https://assets.thermofisher.com/TFS-Assets/MSD/Application-Notes/microstructural-characterization-aging-treated-aluminum-alloy-an0246-en.pdf

- Wolfgang, W. J. (2016). Chemical analysis techniques for failure analysis. Handbook of Materials Failure Analysis with Case Studies from the Aerospace and Automotive Industries.

- Österreicher, J.A., et al (2024). A systematic through-process rolling and extrusion study of four experimental high-strength Al-Mg-Si alloys. Results in Engineering, 23, pp.102384–102384. https://doi.org/10.1016/j.rineng.2024.102384.

- Thermo Scientific Apreo ChemiSEM System Datasheet, Thermo Scientific Apreo ChemiSEM System. https://assets.thermofisher.com/TFS-Assets/MSD/Datasheets/apreo-chemisem-system-ds0508-en.pdf.

- Bobel, A., et al. (2024). Microstructure and mechanical properties of a hypereutectic Al–Si–Cu alloy manufactured by laser powder bed fusion. Materials Science and Engineering A, 901, pp.146549–146549. https://doi.org/10.1016/j.msea.2024.146549.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions.