Ultrasonic Extinction

Acoustic waves scatter when they interact with particles, depending on the wavelength-to-particle size ratio. When transmitting sound energy through a layer of suspension or emulsion, the loss of sound energy due to scattering is directly related to the size and concentration of the particles.

Ultrasonic Extinction differentiates between these effects by employing 31 frequencies and recording a sound attenuation spectrum. The slope of this spectrum indicates particle size, while the amplitude reflects the concentration of particles or droplets.

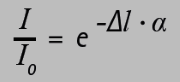

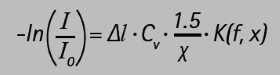

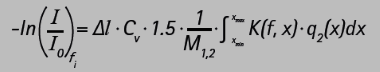

The calculation of particle size distribution and solid or droplet concentration is based on the Lambert-Beer Equation.

In straightforward cases involving monodisperse particles, the size (x) can be determined from the loss of sound intensity (I) relative to the initial intensity (I0) at a specified suspension-layer width (Δl), given the acoustic properties of the material (K(s)).

For systems with distributed particle sizes, this equation is applicable to each particle size class. By defining 31 particle size classes, measurements at 31 distinct frequencies (fi) are necessary to ascertain the size distribution (q2(x)). Given that the sum of all size fractions must total 100%, the concentration (CV) can also be calculated simultaneously.

OPUS

Designed as a robust probe devoid of fragile or moving components, OPUS conducts a comprehensive particle size and concentration analysis in under 90 seconds.

This system can function under demanding process conditions and typically requires no sampling or sample conditioning, such as dilution, deaeration, demagnetization, or regular calibration.

Source: Sympatec GmbH

| Specifications | Quality of measurement results |

| Principle |

Ultrasonic Extinction |

| Measuring range |

< 0.1 μm – 3,000 μm |

| Concentration |

1 – 70 Vol.-% |

| Pressure |

0 – 40 bar |

| Temperature |

-20 °C – 120 °C |

| pH-Value |

1 – 14 |

| Safety Class Rating |

IP65 & ATEX |

| Installations |

in-, on- & off-line |

| Repeatability |

s < 0.5 % |

| Comparability |

s < 5 % |

| Compliance |

ISO 20998-1/2 |

| Material |

Stainless steel 1.4571, 1.4539 (optionally), |

| Hastelloy C22 (optionally), SIGRADUR ®, |

| PTFE | FFKM | FKM |

Process Adaptation

OPUS can operate in full mass flow and is installed in various vessels, reactors, or pipelines of any diameter, utilizing dedicated process adaptors.

Source: Sympatec GmbH

| Adapters |

| AF-Adaters |

For the installation in vessels, reactors or pipes larger than 200 mm. |

| BP-Adapters |

By-Pass-Adapters are designed for the installation in medium size pipes from 25 mm - 50 mm. |

| FT-Adapters |

Small Flow-Through-Adpaters build the link between small pipes from 10 mm - 25 mm and also allow small off-line setup in order to run manual samples in the laboratory. |

MULIPLEXER and Pipe Sampler

Multiple sampling points are connected to a central sample management station for mineral or mining applications involving ore slurries. The MULTIPLEXER manages up to four individual sample streams and fully controls the sampling sequence.

Pneumatic actuators, safety screens, level sensors, and flushing and cleaning nozzles ensure seamless and uninterrupted 24/7 operation. In conjunction with the primary Sympatec Pipe Sampler, MULTIPLEXER, and OPUS provide a turnkey solution for all types of mineral processing and ore-dressing plants.

This information has been sourced, reviewed and adapted from materials provided by Sympatec GmbH.

For more information on this source, please visit Sympatec GmbH.