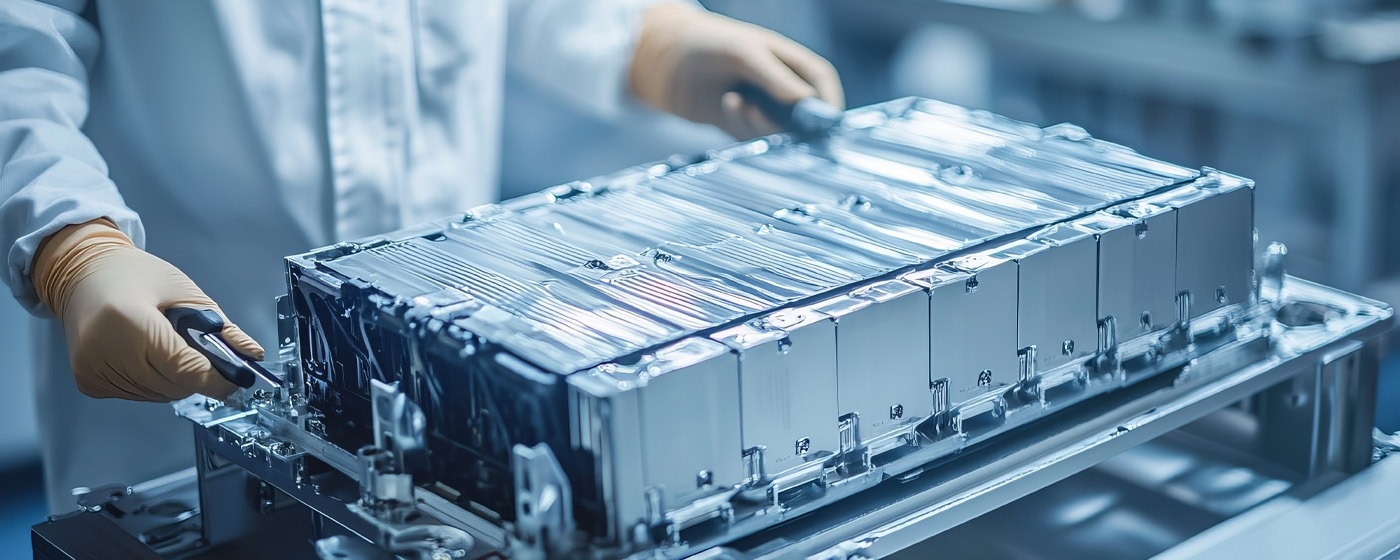

Extreme testing is an essential challenge in the race to develop improved batteries. But how can you ensure consistent results when conditions stretch cooling systems and instrumentation to their limits? One solution is ABB’s physics-based flow measuring technology called the CoriolisMaster.

Image Credit: ABB Measurement & Analytics

The Science of Battery Aging

Modern battery systems are marvels of chemical engineering, but they are also susceptible to a very human issue: aging. Over time, energy storage capacity and power output deteriorate. This process is influenced by a variety of factors, some as unpredictable as the end-user's driving behavior and others as testable as the temperature stress a battery endures.

In the lab, batteries are put through arduous temperature cycles using powerful cooling compressors to simulate real-world circumstances. These systems circulate cooling liquid through battery packs with temperatures ranging from -40 °C to +100 °C. Consistency is crucial in this high-stakes simulation, with exact and real-time knowledge of coolant concentration needed.

Precision in Harsh Environments

Test engineers rely on precise and steady measurement methods to obtain reliable data, even when vibration, pressure swings, or aggressive cooling agents are present. Here, ABB's CoriolisMaster FCB430/450 meters shine.

These Coriolis flowmeters, with a specially programmed concentration table for coolant fluids, provide precise real-time data on coolant concentration. This guarantees that tests are both reproducible and relevant.

The sensor's ability to directly monitor mass flow, density, temperature, and concentration without requiring pressure or temperature compensation makes it a dependable companion in difficult R&D situations.

How It Works: Newton At the Heart of Measurement

The CoriolisMaster's functionality is based on Newton's second law: force equals mass times acceleration. Fluid-filled vibrating tubes produce a quantifiable twist when mass flow is present in Coriolis meters.

This twist reveals what we need to know without being influenced by gravity. No lengthy straight pipe runs are necessary before or after the meter. There are no moving parts or additional sensors. Just a compact, robust design that provides reliable data.

A Coolant Meter with an Engineer’s Mindset

ABB's CoriolisMaster is accurate and designed for field conditions.

Features include:

- A double-tube design, which reduces vibration and manages entrained gas efficiently.

- Low power consumption and stainless-steel construction to provide long-term durability.

- Modular I/O with Modbus and dual pulse outputs to offer flexibility during integration.

Diagnostics, verification, and built-in error messaging simplify troubleshooting if something goes wrong, even through glass using sensitive buttons and intuitive menus.

Smarter Measurement with Enhanced Coriolis Control (ECC)

What makes the CoriolisMaster even more appealing for battery cooling applications is Enhanced Coriolis Control (ECC), ABB's predictive algorithm technology that keeps the meter's oscillation frequency in the sweet spot.

This adaptive technology offers:

- Faster density measurement (1 second vs. 20 seconds)

- Stable results even with gas bubble injection

- Reduced energy consumption during operation

ECC provides peace of mind and improved results in test benches with frequent heat swings and flow changes.

Maintenance Made Easy

Keeping your equipment operational should not feel like a challenge. With ABB's SensorApplicationMemory, all critical data remains with the sensor, allowing for seamless electronics replacement and quick commissioning.

Guided verification, pass/fail diagnostics, and QR code checklists help speed support. Longer calibration intervals and condition-based maintenance result in fewer interruptions and a lower overall cost of ownership.

Conclusion: Ready for the Real World.

Whether users are cycling batteries in a lab or running cooling systems in the field, measurement precision is essential.

Even little fluctuations in coolant content in battery testing might skew data or impair test reproducibility. ABB's CoriolisMaster provides high-precision measurement without operational difficulties.

When pushing the limits of what batteries can accomplish, the instrumentation must be a step ahead.

This information has been sourced, reviewed, and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.