What counts as a smooth surface depends on context. A material considered smooth in one industry may appear rough in another, as the definition varies with sector and application.

Smooth has its own distinct meaning in metrology. When we evaluate the texture of a material with general devices, it can appear relatively smooth. However, observing it under a microscope can dramatically change its topology.

What Does a Smooth Surface Mean?

Wavelength is a central concept in optics, the study of light. It allows scientists to probe materials on scales far smaller than the eye can see, and provides the basis for defining what is smooth in metrology. If the roughness of a material is much less than the wavelength of visible light, we can term it optically or metrologically smooth.

Figure 1. Example of the topography of a smooth surface. Image Credit: Sensofar Metrology

But why is smoothness so important for metrology and optics, in both modern and future technologies?

Why is Smoothness the Key to Our Future?

Performance is dependent on the analysis and production of exceptionally smooth surfaces in optics and semiconductors, among other technologies. Surface quality can determine performance in lenses, chips, and integrated circuits.

As such, surface control has a far-reaching impact, determining efficiency, safety, and dependability in industries ranging from consumer electronics to aircraft, automotive, medical implants, and renewable energy.

Understanding and characterizing these ultra-smooth surfaces as technologies combine and evolve is critical to the next wave of innovation.

How Could Metrology Help in the Next Technological Revolution?

Metrology is key here because it can solve many of the major problems in surface science by taking high-precision measurements. Recently introduced materials in research and industry demand highly accurate measurements of shape, roughness, bumpiness, flatness, and flaws.

In this context, metrology and imaging techniques are the primary methods for characterizing smooth surfaces. Interferometry remains the best for accuracy and reproducibility.

Interferometry: The Secret to Measuring the Smooth Surfaces

There are several methods using interferometry to measure smooth surfaces, although they differ in how they extract the interference pattern.

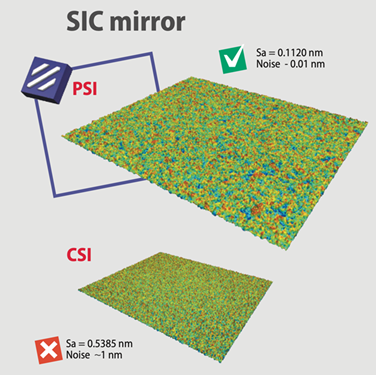

First, Coherence Scanning Interferometry (CSI) provides measurement noise or height resolution down to one nanometer. Another approach, Phase Shifting Interferometry (PSI), is better suited for measuring smooth surfaces with sub-angstrom vertical resolution.

Figure 2. PSI, ePSI, CSI. Description: Topographies of the same surface measured with interferometry techniques: PSI, ePSI and CSI. Image Credit: Sensofar Metrology

Alternatively, Extended Phase Shifting Interferometry (ePSI) combines the advantages of both CSI and PSI methods.

The best approach is dependent on the measurements and the material itself. However, the choice of 3D profilometer is the determining factor for the most precise approach to measure the features of a smooth surface.

The most important factors to look for in an interferometer are performance, which refers to the system's resolution in XY and Z dimensions as well as its accuracy and repeatability, its software, automation capabilities, and acquisition and analysis facilities; and finally, the profilometer's versatility, which indicates a system that can cover a variety of techniques.

Figure 3. SiC Wafer. Description: Flatness characterization of a SiC wafer using S neox. Image Credit: Sensofar Metrology

Sensofar provides an excellent optical profilometer for measuring exceedingly smooth surfaces, including techniques such as interferometry (PSI, CSI, and ePSI).

These methods play a pivotal role in driving forward the next technological leaps by enabling precise measurement of ultra-smooth surfaces.

This information has been sourced, reviewed, and adapted from materials provided by Sensofar.

For more information on this source, please visit Sensofar Metrology.