Electric cars (EVs) have become increasingly popular over the past decade. Their greater efficiency, sustainability, and cost savings make this popularity clear. However, batteries capable of creating these types of technologies require great performance, which can be achieved with metrology, with its strict quality and safety criteria.

Why Does Metrology Play a Crucial Role in EV Batteries?

When manufacturing batteries for EVs, precise control is required, as any defect or departure could jeopardize the battery's performance and safety.

Metrology is a key component in every process of building an EV battery. For example, material roughness might affect the coating process in electrode preparation, which must be regulated to ensure good adherence.

It is also applicable to battery construction itself, where the roughness of electrode sheets may be monitored to assure uniformity across cells and prevent flaws such as fractures or delamination.

Non-contact 3D optical techniques allow fast, precise, and non-destructive surface measurements throughout these critical quality control phases.

When combined with SensoPRO plugins, Sensofar profilers can provide automated and reproducible measurements of roughness, flatness, and thickness across battery layers, separators, and components.

By combining confocal microscopy, interferometry, and AI focus variation technologies, manufacturers can increase consistency, yield, and safety requirements in EV battery production.

How Can Metrology Improve the Life of Batteries?

Generally, industry would prefer to replace a dead battery rather than fix it. But restoring them is both less expensive and more environmentally friendly. Where this is true, metrology may be the solution to extending battery life and lowering costs across the board.

Sensofar's battery applications highlight the ways metrology can help EV battery manufacturing and repair. Real-world examples demonstrate how optical techniques can ensure both performance and safety.

One major approach to increasing battery life is measuring and characterizing the surface properties of battery components. Surface roughness, flatness, thickness, and morphology, as well as adhesion, conductivity, and capacity retention, can all impact battery performance.

Sensofar's non-contact 3D optical profilers generate high-resolution data on key parameters, ensuring consistent findings in new and refurbished batteries.

The most important characteristic in determining battery quality is surface roughness. A rough surface can impact the electrochemical activity of electrode layers, adhesion to other materials, contact resistance, and heat dissipation.

Sensofar's areal roughness analysis allows manufacturers to look beyond line profiles and obtain a complete, 3D perspective of electrode surfaces, helping to enhance performance and longevity.

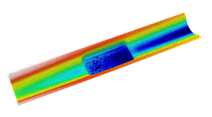

Figure 1. Flatness, description: Topography of System-in-Package (SiP) package flatness with high precision. Image Credit: Sensofar Metrology

Inspecting the roughness of the battery's constituent layers is also critical for improving performance and can result in greater longevity.

Packaging technology Systems in packages (SiP) combine numerous components into a single unit, saving space and simplifying wiring. 3D optical profilometers use interferometry techniques to detect SiP package flatness with great precision and repeatability.

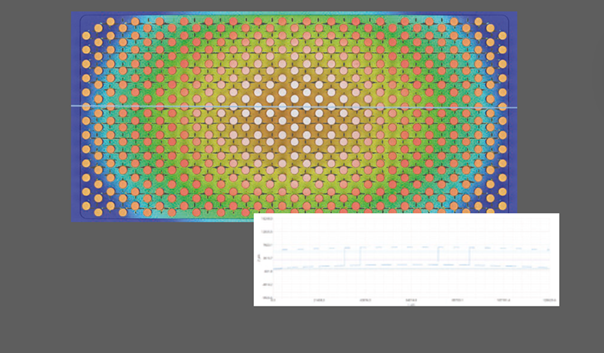

Figure 2. SiP, description: Topography of a heat sink surface, showing flatness deviations assessed with Fringe Projection to ensure efficient battery cooling. Image Credit: Sensofar Metrology

Another significant factor influencing battery performance is heat sink flatness, which affects efficiency. Sensofar uses Fringe Projection to quickly and accurately assess heat sink geometry, ensuring optimal assembly and cooling.

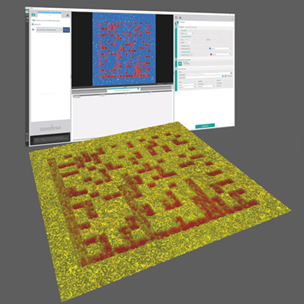

Figure 3. Barcode engraving, description: Topography using Fringe Projection to measure barcode engraving. Image Credit: Sensofar Metrology

Cell safety depends heavily on the battery separator, because it prevents direct contact between the two electrodes responsible for electron flow during battery operation.

Sensofar's optical areal metrology detects potential faults on porous membranes, ensuring continued separator quality in high-energy lithium-ion cells.

Figure 4. BGA, description: Optical characterization can assess the uniformity of BGA pin heights, which is crucial for connection reliability. Image Credit: Sensofar Metrology

Each of these aspects is critical for the quality and safety of all EV batteries. Repairing these issues (instead of replacing batteries) could make electric vehicles more durable and safe.

These are some examples of why metrology is essential for quality control and precise measurements of new and repaired EV batteries. By ensuring accuracy at every production stage, metrology helps lower costs, reduce manufacturing times, and avoid battery faults.

This information has been sourced, reviewed, and adapted from materials provided by Sensofar.

For more information on this source, please visit Sensofar Metrology.