Scientists and engineers working on battery development or manufacturing know just how hard it can be to monitor, understand, and control the many factors that influence cell performance.

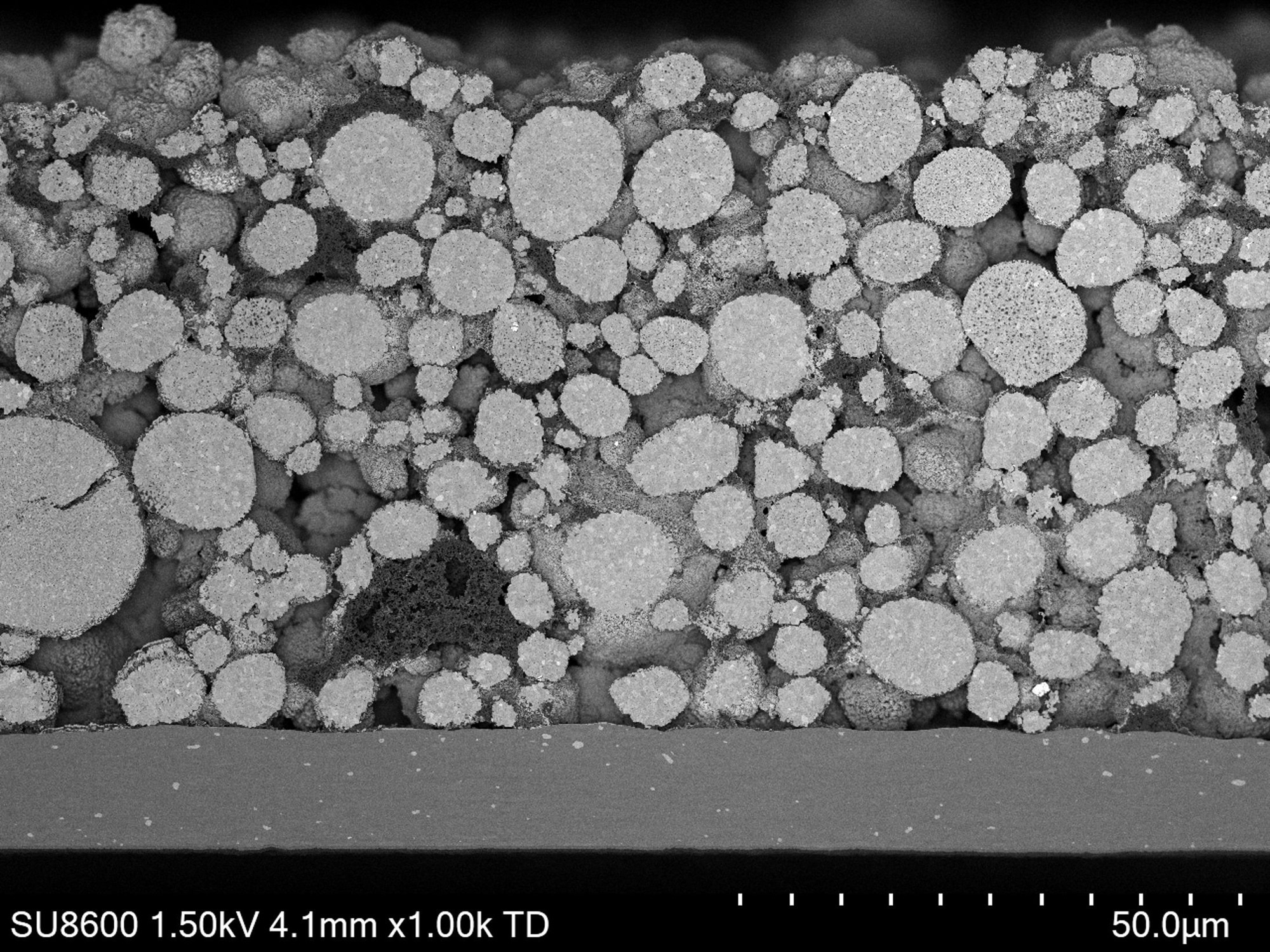

Image Credit: Hitachi High-Tech Europe

This whitepaper explores how advanced cross-sectional analysis of electrodes using SEM and broad ion beam (BIB) milling is helping researchers and manufacturers develop better batteries.

What you’ll learn:

- How to study and quantify critical electrode parameters such as coating thickness, particle size, SEI formation-tortuosity, binder distribution, and cracking

- Why Broad Ion Beam Milling is the ideal technique for electrode cross-sectioning

- How automation and AI are transforming image analysis and QC

- How to reliably study electrodes after formation or cycling using vacuum transfer

- Preparing ultra-wide cross-sections for improved statistical control

Download your copy now to get all the information you need to develop better batteries.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Europe.

For more information on this source, please visit Hitachi High-Tech Europe.