Multi-layered auto body coatings play two primary roles: the protection of the vehicle’s body from corrosion and the enhancement of a car’s aesthetic presentation. From an operational perspective, automotive painting is also the most expensive element of automobile assembly.

Researchers and industrial practitioners have expressed considerable interest and effort in better controlling and monitoring the painting process in order to improve the quality of coatings and their mass production. This has included consideration of factors such as layer thickness and chemical composition.

This article outlines the use of the Thermo Scientific™ Helios™ 5 Laser Plasma FIB in a novel approach to the high-throughput automated cross-sectioning of car paint coatings.

Paint quality was historically determined by analyzing paint coating samples embedded in polymer resin blocks. This time-consuming approach relies on the use of multi-step mechanical polishing to produce a cross-section of the paint on a steel body substrate. It is also difficult to produce the extremely smooth surfaces required for high-quality analysis via this method.

On the other hand, Gallium focused ion beam (FIB) milling can only reasonably produce cross-sections of samples that are 20 µm wide and deep. Paint layer thickness can be more than 100 µm thick, making also this method unsuitable for accessing paint samples.

Even xenon plasma FIB can struggle to create pristine cross-sections wider and deeper than a few hundred microns in a time-efficient manner, because it requires low-current polishing and the application of a thick protective layer before cross-sectioning takes place.

The Helios 5 Laser Plasma FIB features the robust combination of a fully integrated femtosecond laser, scanning electron microscope (SEM), and FIB.

Helios 5 Laser PFIB. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

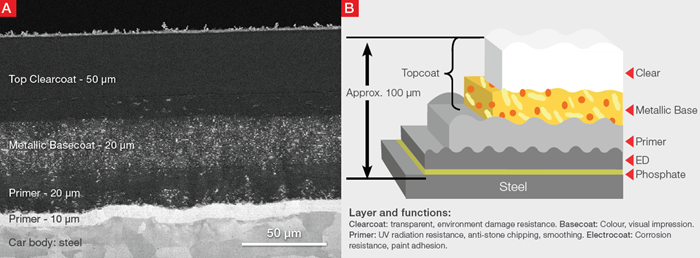

The instrument’s laser facilitates rapid, millimeter-scale material removal with no requirement for a protective layer. The different layers of the paint structure are shown in Figure 1.

Figure 1. A) SEM backscattered electron image of an auto body coating cross-section. B) Typical four-layer automotive paint structure. Schematic drawing is modified, with permission, from Akafuah, N, Poozesh, S, et al. Evolution of the Automotive Body Coating Process - A Review. Coatings, 6(2), 24. 2016. doi:10.3390/coatings6020024. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

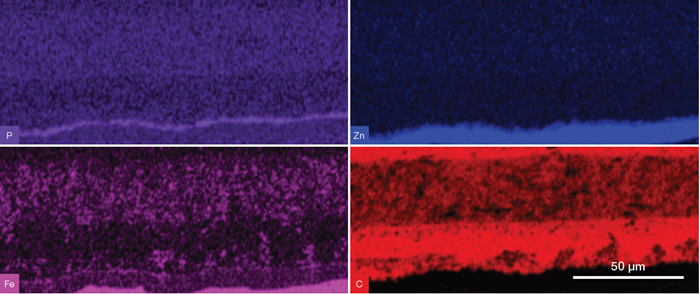

It also combines SEM and EDS (energy-dispersive X-ray spectroscopy), allowing its users to reveal the paint layers’ structural and chemical details. The EDS characterization of the layers in Figure 2 shows the distribution of phosphorus, zinc, iron, and carbon, originating respectively from the phosphate layer, the electrogalvanized coating, the steel substrate, and the primer.

It is worth noting that both cross-section preparation and imaging were performed using the Thermo Scientific Helios 5 Laser Plasma FIB. The cross-section was prepared using only the integrated in-chamber laser, without a PFIB clean up step. This demonstrates the high quality of femtosecond laser processing which enables the instrument to maintain high-throughput characterization.

Figure 2. EDS elemental maps clearly correlate to the paint structure shown in Figure 1. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

This powerful combination allows for rapid feedback as part of ongoing auto body coating quality control. EDS results also confirm that that cross-section chemical information is not changed by the in-chamber laser ablation process.

Acknowledgments

Produced from materials originally authored by Thermo Scientific.

Download Thermo Scientific's Automotive eBook

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions.