In this interview, industry experts Janam Pandya and Tom Dearing discuss how Raman spectroscopy and chemometric modeling are transforming fuel and lubricant quality monitoring by enabling accurate, repeatable, and real-time analysis directly within refinery processes.

To get started, can you explain why accurate, refined fuel property analysis is so important in refinery operations?

Janam Pandya: Refineries operate under extremely regulated conditions, and blended fuels must meet strict quality and compliance standards set by ASTM-certified test methods. Accurate fuel property analysis is essential to ensure that products meet these specifications.

Additionally, refinery profit margins are tight, so maintaining tighter specifications helps optimize blending efficiency and minimize waste. Transitioning from offline laboratory testing to continuous in-line quality control enables faster decision-making, enhanced oversight, and real-time process optimization.

This shift reduces delays, prevents off-spec production, and enhances overall operational efficiency.

What are some of the main challenges with conventional quality control workflows in refineries?

Janam Pandya: Traditional quality control in refineries often depends on offline laboratory testing. Samples are collected manually and transported to a quality control lab where instruments such as gas chromatographs, knock engines, and vapor pressure analyzers are used to determine key fuel properties. This workflow introduces several limitations.

First, offline testing is inherently time-consuming. Each sample may take hours to analyze, which delays feedback to the process line. During that time, the process continues to run, potentially producing off-spec material that must later be reprocessed or discarded.

Second, manual sampling increases the risk of contamination, measurement error, and inconsistencies between batches. Third, the instruments used in these analyses require significant maintenance, calibration, and consumables such as carrier gases. These costs add up quickly.

Another major challenge is data continuity. Offline results are often reviewed after production decisions have already been made, meaning adjustments to blending or refining parameters come too late to prevent losses. Without direct in-line feedback, operators are essentially making decisions based on historical rather than real-time data.

In the current refining environment, where margins are narrow and efficiency is critical, these limitations highlight the growing need for continuous, automated monitoring methods.

How does Raman spectroscopy work for in-line fuel monitoring?

Janam Pandya: Raman spectroscopy measures the vibrational energy of molecules to provide a unique spectral fingerprint of a substance. In an in-line configuration, a laser is directed through an optical fiber into the process stream. When the light interacts with the hydrocarbons in the fuel, a small fraction of it scatters at different wavelengths.

This scattered light, known as Raman scattered light, carries information about the molecular bonds present in the sample. The light then travels back through the fiber to the spectrometer, which interprets it as a Raman spectrum.

Each component of a fuel blend, such as aromatics, olefins, paraffins, and additives, has distinct vibrational modes, allowing Raman spectroscopy to detect compositional differences in real time. Using chemometric models, these spectra are transformed into quantitative data for specific properties like octane number, vapor pressure, or sulfur concentration.

The beauty of in-line Raman is that it requires no sample preparation, no consumables, and no carrier gases. Measurements are direct, non-destructive, and can be made in seconds. This makes it ideal for continuous process control, providing engineers with immediate data to make adjustments and maintain fuel quality without interrupting production.

What advantages does the MarqMetrix all-in-one Process Raman Analyzer offer?

Janam Pandya: The MarqMetrix all-in-one Process Raman Analyzer is extremely compact, about the size of a laptop, and can be mounted near the process stream or in an analyzer shack. It comes factory-calibrated, requires minimal yearly maintenance, and operates with a simple one-button interface. It also integrates seamlessly with process control systems via Modbus or OPC protocols.

With its robust BallProbe technology, Hastelloy construction, and sapphire optical interfaces, the system withstands harsh conditions, including pressures up to 6,000 PSI and temperatures ranging from -250 °C to +300 °C. It’s also ATEX and IECEx certified for hazardous environments, ensuring both safety and reliability.

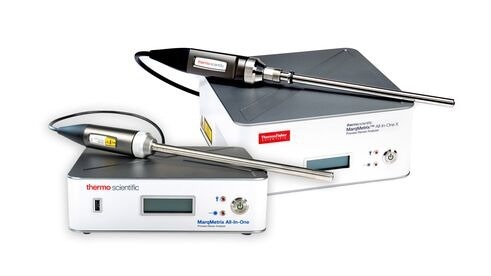

Thermo Scientific™ MarqMetrix™ All-in-One Process Raman Analyzer and MarqMetrix™ All-in-One X Process Raman Analyzer (for hazardous locations). Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

How does chemometrics enhance Raman spectroscopy for process monitoring?

Tom Dearing: Chemometrics is the mathematical foundation that bridges raw spectral data and actionable information. Essentially, it combines statistical and machine learning techniques to extract meaningful chemical property values from complex spectra. The process begins by collecting spectra alongside reference ASTM data that represent known fuel properties.

These datasets are used to build predictive models, which can then estimate properties like octane number, flash point, or viscosity based purely on Raman spectra.

Once developed, these models are implemented on the instrument for real-time prediction. As the process runs, the instrument continuously collects new spectra, applies the chemometric models, and outputs live values for key properties.

This combination of Raman spectroscopy and chemometrics allows refiners to monitor composition changes instantaneously and make informed decisions with confidence.

What results did you observe in real-world refinery testing with the MarqMetrix all-in-one Process Raman Analyzer?

Tom Dearing: We collected around 300 refinery samples across gasoline, diesel, and jet fuels and built approximately 15 predictive models. The models for properties like API gravity, RON, MON, RVP, cetane, and flash point showed excellent correlation with ASTM reference methods.

For example, RON and MON models demonstrated strong linearity and repeatability. We also found the system could distinguish between premium and regular gasolines, as well as between jet and diesel fuels, highlighting the analyzer’s precision. The standard deviations in repeatability tests were very small, confirming consistent accuracy and reliability.

Can you describe how this technique performs when applied to base oils and lubricants?

Tom Dearing: We extended our evaluation to base oils from both API Group II and Group III to determine whether Raman spectroscopy could effectively predict lubricant properties. The spectra for these samples showed clear differences in molecular structure, which enabled precise modeling of viscosity at 40 °C and 100 °C, simulated distillation points (IBP, T50), pour point, Noack volatility, and aromatic content.

The resulting models demonstrated excellent correlation with ASTM D86 reference data, and repeatability was outstanding, with deviations often within a single degree Fahrenheit.

These findings indicate that Raman spectroscopy can provide the same level of insight into lubricant base oils as it does for fuels, allowing manufacturers to track quality parameters continuously without interrupting production.

How are these chemometric models used in real-time refinery operations?

Tom Dearing: Once the chemometric models are validated, they are embedded within the MarqMetrix all-in-one Process Raman Analyzer to enable real-time prediction and process feedback.

Our software packages enable seamless model deployment: Spexware handles calibration data collection, while Runspex runs directly on the instrument to perform continuous property predictions such as octane number or viscosity.

The software automates acquisition, analysis, and reporting, with results instantly viewable by operators. Data can be exported through standard communication protocols such as Modbus or OPC-UA, or as text files for integration with LIMS systems.

This connection between measurement and control ensures that refineries maintain consistent product quality and make immediate, data-driven adjustments during operation.

How much maintenance or calibration does the MarqMetrix all-in-one Process Raman Analyzer require?

Janam Pandya: The instrument is factory-calibrated and does not require recalibration once installed. Routine maintenance is minimal, typically consisting of an annual performance check to verify the function of the detector, laser, and optics. Occasionally, fiber-optic connections might need cleaning, but that’s about it. The system is designed for long-term reliability and minimal operator intervention.

How durable are the optical probes used for in-line measurements?

Janam Pandya: The probes are built to withstand the demanding conditions of refinery environments. They are constructed from corrosion-resistant materials, such as Hastelloy, and feature a sapphire optical window that withstands extreme pressure and temperature.

The spherical sapphire tip is particularly important because it naturally sheds buildup as the process fluid moves past it, keeping the optical surface clean. This self-cleaning behavior means that, in most applications, probes can remain in service for extended periods without manual cleaning. Only in cases involving very viscous or particulate-laden fluids would occasional inspection be necessary.

What would you highlight as the main takeaway from your work with Process Raman spectroscopy?

Janam Pandya: Our results demonstrate that Process Raman spectroscopy can deliver precise, repeatable measurements that align closely with ASTM reference methods. The ability to measure multiple properties simultaneously, without sample preparation or consumables, provides a practical way to bring laboratory-level accuracy directly to the process line.

This technology supports real-time decision-making, faster optimization, and consistent product quality, which are all essential in refinery and lubricant production.

Tom Dearing: I would add that the repeatability and robustness we observed give real confidence in the numbers produced by the instrument. The correlation between Raman predictions and ASTM results was excellent, and the measurements remained stable over time. These strengths show that Raman spectroscopy is a reliable and efficient solution for continuous fuel and lubricant quality monitoring.

Want to learn more? Watch the full webinar on this topic

About Thomas Dearing

Dr. Dearing holds a Ph.D. in Chemometrics from the University of Hull and completed postdoctoral research at the University of Washington. He now works at Thermo Fisher Scientific as the Chemometrics Product Manager, advancing analytical methodologies and data-driven approaches within the organization.

About Janam Pandya

Dr. Pandya has worked at Thermo Fisher Scientific’s Boston, MA office since 2022, where he focuses on expanding the use of Raman spectroscopy for real-time process monitoring. He partners with major customers across biopharma, pharmaceuticals, polymers, food, clean energy, and other sectors to support the successful adoption of Process Raman Analyzers as PAT solutions.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy.

For more information on this source, please visit Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.