Precision and safety go hand in hand when operating in hazardous environments. Facilities handling flammable gases, volatile solvents, or combustible dusts require analytical equipment that delivers precise results while meeting rigorous safety standards to prevent fire or explosion.

This article outlines what constitutes a hazardous location, explains its classification systems, and highlights key considerations for installing Raman analyzers in these environments for safe, real-time process monitoring.

What is a Hazardous Location?

A hazardous location is any area where flammable gases, vapours, dust, or fibers are present in amounts that could trigger a fire or explosion. These environments are common in oil and gas, petrochemical processing, and pharmaceutical industries.

Hazards arise when flammable substances combine with oxygen and a potential ignition source. Measurement devices must be designed and certified for safe operation in such settings.

Understanding Hazardous Location Classifications

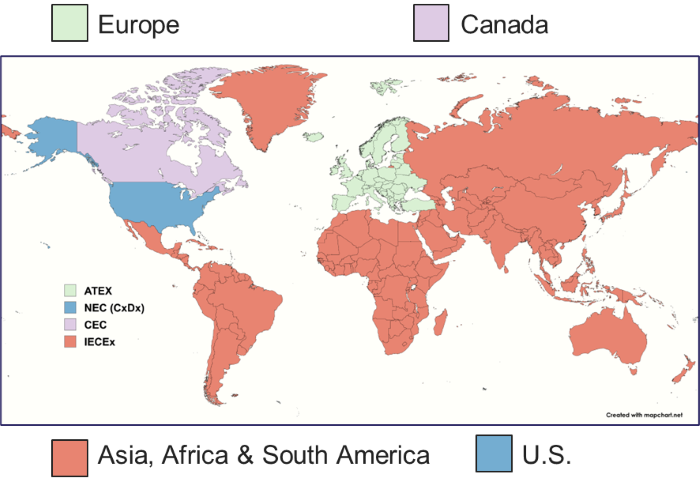

Hazardous areas are strictly regulated to prevent electrical or mechanical equipment from igniting flammable materials. International classification systems define the type and level of risk, specifying which instruments are safe to use and what certifications they must carry.

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

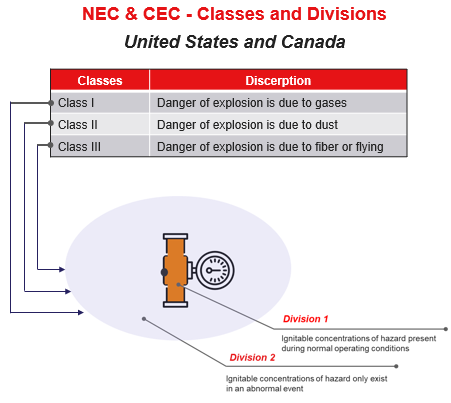

NEC / CEC (North America)

The United States and Canada classify hazardous environments using the Class/Division system, which is defined by the National Electrical Code (NEC) and Canadian Electrical Code (CEC).

- Classes

- Class I: Areas where flammable gases or vapors are present in the air in quantities sufficient to form explosive or ignitable mixtures.

- Class II: Areas where combustible dust is present.

- Class III: Areas where ignitable fibers or flyings are present.

- Divisions

- Division 1: Hazards are present during normal operating conditions.

- Division 2: Hazards are present only under abnormal conditions.

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

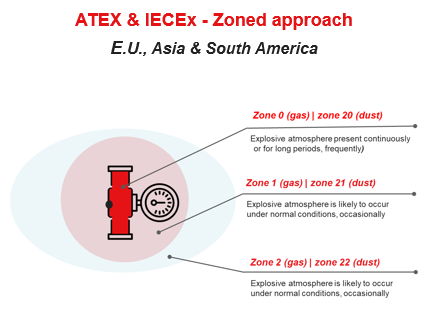

ATEX (Europe)

ATEX (from the French ATmosphères EXplosibles) is the European Union directive governing equipment designed for use in explosive atmospheres. ATEX has a zone system based on the probability and duration of exposure to explosive gases or dusts.

- Zone 0 (gas), Zone 20 (dust): Explosive atmosphere is present continuously or for extended periods.

- Zone 1 (gas), Zone 21 (dust): Likely to be present under regular conditions.

- Zone 2 (gas), Zone 22 (dust): Unlikely to occur, and if it does, only for a short period.

IECEx (International)

IECEx is the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres. It provides globally harmonised certification, ensuring manufacturers and end-users can safely operate in hazardous areas.

IECEx:

- Uses the same classification system as ATEX (Zone 0, 1, 2 for gases; Zone 20, 21, 22 for dusts).

- Based on IEC standards (e.g., IEC 60079) to ensure global uniformity.

- Streamlines the deployment of certified equipment across various countries, reducing the need for regional re-testing or re-certification.

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

Source: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

| System |

Region/

Origin |

Classification

Approach |

Hazard Zones/

Levels |

Equipment Groups/

Categories |

Key Notes |

| NEC / CEC |

North America

(U.S. / Canada) |

Class / Division system |

- Class I: Gases/Vapors

- Class 2: Dust

- Class 3: Fibers/Flyings

- Division 1:

Normal operation

- Division 2: Abnormal conditions

|

Not grouped

like ATEX/IECEx |

Widely used in the U.S. and Canada; based on presence likelihood and material type |

| ATEX |

European Union |

Zone system |

- Zone 0 (gas), 20 (dust): Continuous presence

- Zone 1 (gas), 21 (dust): Likely during normal operation

- Zone 2 (gas), 22 (dust): Unlikely or short duration

|

- Group I: Mining

- Group II: Industry

|

EU Directive (2014/34/EU); legal requirement in EU countries |

| IECEx |

International (Global) |

Zone system (same as ATEX) |

- Zone 0, 1, 2 (Gases)

- Zone 20, 21, 22 (Dusts)

|

Same as ATEX (follows

IEC 60079 standards) |

Globally harmonized; facilitates

multi-country equipment certification |

Common Challenges with Analytical Instruments in Hazardous Process Monitoring

There are several challenges in monitoring hazardous environments due to the unique conditions involved.

- Ignition risk: Sparks or elevated surface temperatures may initiate combustion.

- Limited accessibility: Equipment is frequently installed in hard-to-reach zones, complicating routine maintenance.

- Environmental extremes: Vibration, dust, humidity, and high or low temperatures can affect sensitive tools.

As a result, it’s essential to choose instruments that are robust and compliant with safety regulations.

Why Raman Spectroscopy is Ideal for Process Monitoring in Hazardous Environments

Raman spectroscopy enables non-destructive, real-time evaluation of chemical composition without requiring sample transport or preparation. This method is especially well-suited for process monitoring in hazardous applications due to the ability to:

- Analyze gases, liquids, and solids directly in-line.

- Operate through sight glasses or flow cells.

- Provide immediate feedback for process control or safety decisions.

The new generation of Raman analyzers is compact and durable, requires no calibration, and requires minimal preventive maintenance. Additionally, sampling optics are specifically engineered to endure corrosive environments, high temperatures, and elevated pressures.

With certified equipment and proper installation, Raman analyzers can help optimize production, enhance safety, and minimize downtime even in the most demanding industrial settings.

Key Considerations When Selecting Raman Analyzers for Hazardous Areas

The following requirements and features must be considered when choosing Raman analyzers for hazardous environments:

- Certification for ATEX/IECEX Zone 0 or 20, Class I, II, or III with Div 1, indicating that the analyzer is engineered for safe operation.

- Inherent safety and optical radiation protection.

- Compliance with T-rating standards via low surface temperature and thermal stability.

- Remote control and diagnostics to reduce the need for physical access

- No calibration and minimal preventive maintenance for hard-to-reach hazardous environments.

- Durable probes/optics built to endure elevated temperature, pressure, and corrosive environments.

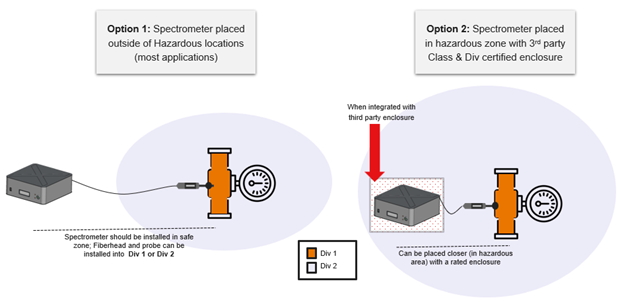

Typical Raman Analyzer Installation for Process Monitoring in Hazardous Environments

The base spectrometer, often containing the laser, detector, computer, and most electronics, is deployed in a non-hazardous (safe) area whenever possible.

When base spectrometers must be placed in hazardous areas, they are typically housed in explosion-proof enclosures equipped with purge systems.

A fiber optic cable with a sampling probe, connected to the base spectrometer via an intrinsically safe circuit, is then utilized for hazardous process monitoring.

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

The system is integrated into facility safety protocols, such as emergency shutoff and pressure relief measures.

Key Takeaways

Precise classification and the right certified equipment are vital in hazardous environments, where even a spark can trigger disaster.

Approved by ATEX, IECEx, NEC, or CEC, Raman analyzers can combine robust design and remote sampling to operate safely under these conditions. Offering rapid, reliable monitoring without the need to move samples, they provide a safer, more efficient way to track chemical processes where it matters most.

Ready to See How it Works?

Accurate natural gas measurements are crucial in any environment. The following application note explains how Raman spectroscopy, combined with chemometric modelling, provides a powerful solution. Read it here.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy.

For more information on this source, please visit Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy.