Vanessa Gutierrez, Senior Researcher in Mechanical Recycling Group at AIMPLAS

A recyclability assessment consists of a standard procedure (protocol), performed on a plastic component (flexible or rigid packaging, automotive or EEE part), to validate the compatibility of an innovative material (e.g., functional barrier, adhesive, printing, etc.) with a given recycling stream.

In the medium to long term, the proven compatibility of these materials will help meet the objectives of the current and future European Directives and Regulation, and ensure good-quality recycled materials, reducing pollution from plastic waste and avoiding less sustainable end-of-life options (incineration and landfill). RecyClass recognizes AIMPLAS for performing the recyclability evaluation of flexible products (PE and PP films) and automotive and EEE products (PP and ABS components), as well as for evaluating the recyclability of PE films through APR and the recyclability of PET trays through Petcore.

The Protocols

The main protocols for conducting recyclability assessments have been developed by Plastics Recyclers Europe (RecyClass Recyclability Protocol) and PETCORE, targeting the European market, and the Association of Plastic Recyclers (APR Critical Guidance), targeting the American market. Currently, these organizations are collaborating on the harmonization of their protocols to facilitate companies' ability to receive multiple recognitions for the execution of one of them.

When performing a recyclability evaluation, several considerations must be taken into account, such as:

- Materials to be evaluated

- Procedure to follow

- Technical and scientific approach of recyclability assessments

1. Materials to Be Evaluated

Two materials are described in the protocols for the recyclability assessment:

- The Innovation material

- Control material

The Innovation material is any material or feature contained in the plastic product, incorporated to improve performance, and usually its effect on recyclability is unknown. Some of these elements are the following:

- Coatings, co-extrusions and laminates (coatings, barriers and adhesives), aluminized and other unspecified products

- Rigid fasteners for film containers, such as valves and closures

- Mineral fillers and other additives that alter the density of the part

- Tags and labels

- Inks and pigments, including direct, reverse, laminated, and other printing technologies

- Compatibilizers and other unspecified additives

Figure 1. Flakes obtained during the pre-treatment phase. Image Credit: AIMPLAS

Some of these materials have already been previously validated and approved as compatible in specific recycling streams and are included in the design guides for recycling of the respective organizations; therefore, it is not necessary to evaluate them through these protocols. However, materials that have not yet been validated, that are above the concentrations evaluated, or that are in combination with other elements, must be subjected to these evaluations.

The Control material is a reference plastic with verified recyclability, and it’s used to comparatively evaluate the performance of the Innovation materials. The control can be of diverse types, but in general, the control should have the same critical technical specifications with respect to MFI and density as the base of the Innovation material. On the other hand, virgin resins can be used as controls (reprocessed) only when the innovation to be evaluated is also presented in the form of granules or resin, or their use is approved by the respective organization.

2. Procedure to Follow

Before requesting and conducting a recyclability assessment, an official procedure must be followed, either when opting for the RecyClass route or the APR route. The main steps are as follows:

Step 1: Contact and request from the respective organization body (RecyClass or APR). In this first stage, the technical teams of the organizations will review the application, verifying that the Innovation material is suitable for a homologation/recognition process. In this step, they will also indicate any variation of the protocol to be used and will define, together with the interested party, the Control material to be used.

Step 2: Contact the accredited laboratory. With the instructions provided by RecyClass or APR, the interested party can contact an accredited laboratory to proceed with the evaluation, supplying the necessary materials.

Step 3: Execution of the protocol. The laboratory conducts the recyclability assessment at pilot plant scale, and generates a complete report to share with the body selected for approval.

Image Credit: AIMPLAS

Step 4: Review of the results. The respective agency evaluates the results and meets with the interested party. Depending on the results, these are then reviewed by a Technical Committee, which will decide the final result of the homologation, and the following possible cases may be found:

- RecyClass: Full Compatibility, Limited Compatibility or Low Compatibility

- APR: Preferred, according to APR Design Guide, Detrimental to Recycling or Renders Package, Non-Recyclable Packaging

3. Technical and Scientific Approach to Recyclability Assessments

Recyclability assessments simulate the basic steps conducted in conventional recycling facilities and their subsequent transformation into final products. These are divided into three main stages: pre-treatment, extrusion, and conversion. Each one is described below.

-

- Pretreatment. It mainly includes crushing and washing operations, which are carried out on the materials already separated into specific streams (flexible PE and PP, rigid HDPE and PP, PET, PS, ABS). In this phase, it’s verified, among other things, that there is a complete separation by flotation, the color of the washing water and the presence of particles, the homogeneous size of the flakes after crushing, that they have easy flow, and that the bulk density is adequate.

The main reason for evaluating the behavior of pretreatment is to ensure that Innovation materials behave like conventional materials in standard recycling streams.

-

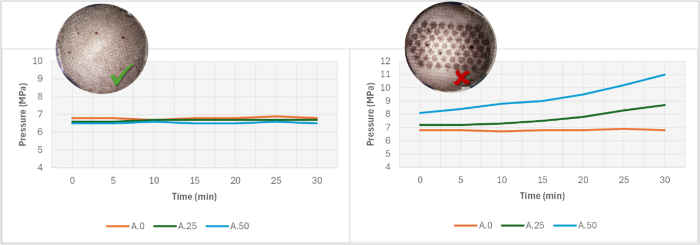

- Extrusion. In the extrusion phase, two mixtures of Innovation and Control materials are prepared (25, 50, or 100%, depending on organization requirements), filtered and pelletized, and compared with the Control material to ensure processability, process stability, and pellet quality. Aspects such as accumulation in the extrusion die (die build-up), that the pellets have a homogeneous appearance, with low yellowing compared to the control, the stability of the process: increase in torque and pressure (saturation of filters), as well as the physical properties of the pellets obtained, are monitored and tested.

Figure 2. Comparison of processing behavior during pellet production. Left: Good (stable pressure, clean filter); Right: Poor (pressure rise, filter clogging). Image Credit: AIMPLAS

-

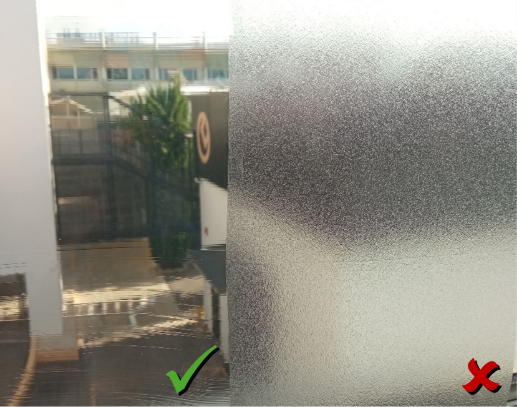

- Conversion. In the conversion phase, innovation blends are processed and compared to the control to verify the effect on a final product, with respect to processability, process stability, and product performance. The following aspects are supervised: process stability: torque and pressure, stability of films or sheets, general appearance (gels, specks, holes, melt fracture, line breaks, accumulation of residues in nozzle and/or tooling, etc.), as well as the appearance and mechanical performance of the products obtained.

Figure 3. Qualitative evaluation of a PO film. Left: Good (low gels, low haze); Right: Poor (remarkably high gels, high haze). Image Credit: AIMPLAS

Final Remarks

It is worth noting that the primary purpose of recyclability assessments is to verify the recyclability of novel and innovative materials within a standard recycling stream.

The APR, RecyClass, and Petcore’s protocols, as well as other existing protocols, verify the effect of these materials/structures in a controlled scenario, considering a scenario equivalent to a post-industrial recycling process or in a closed loop.

If such materials have a low or no effect on the quality of the evaluated stream, they will also have a low or no effect on a post-consumer recycling stream. Ensuring the recyclability of the product will enable it to meet the EU's directive targets.

This information has been sourced, reviewed and adapted from materials provided by AIMPLAS.

For more information on this source, please visit AIMPLAS.