Multilayer films have long been used in food and drink packaging as they meet several specifications in terms of barrier characteristics, mechanical integrity, and functional properties.

Image Credit: Molecular Vista

In recent years, in addition to traditional techniques including coextrusion and lamination, nanotechnology has been applied to produce composite multilayer films with improved properties.

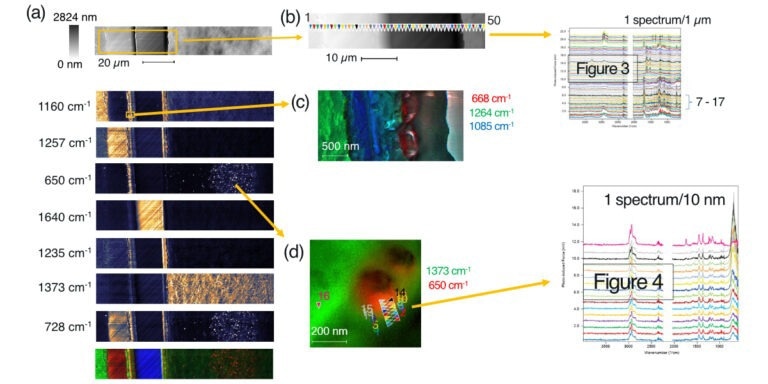

Traditionally, Fourier Transform Infrared Spectroscopy (FTIR) has been used to chemically analyze cross-sectioned samples of multilayer materials. More recently, more sophisticated IR methods (AFM-IR and O-PTIR) have been employed to address the diffraction limit of FTIR, which prevents the analysis of component layers thinner than approximately 5 µm.

O-PTIR offers a spatial resolution of around 0.5 µm, providing greater flexibility. However, it also falls short of the required spatial resolution for more advanced packaging materials that incorporate nanoparticles or ultrathin layers.1

Although AFM-IR (PTIR type) delivers improved spatial resolution, it presents challenges in sample preparation, as thin microtome cross-sectional samples must be placed on an IR-transparent substrate for analysis.2

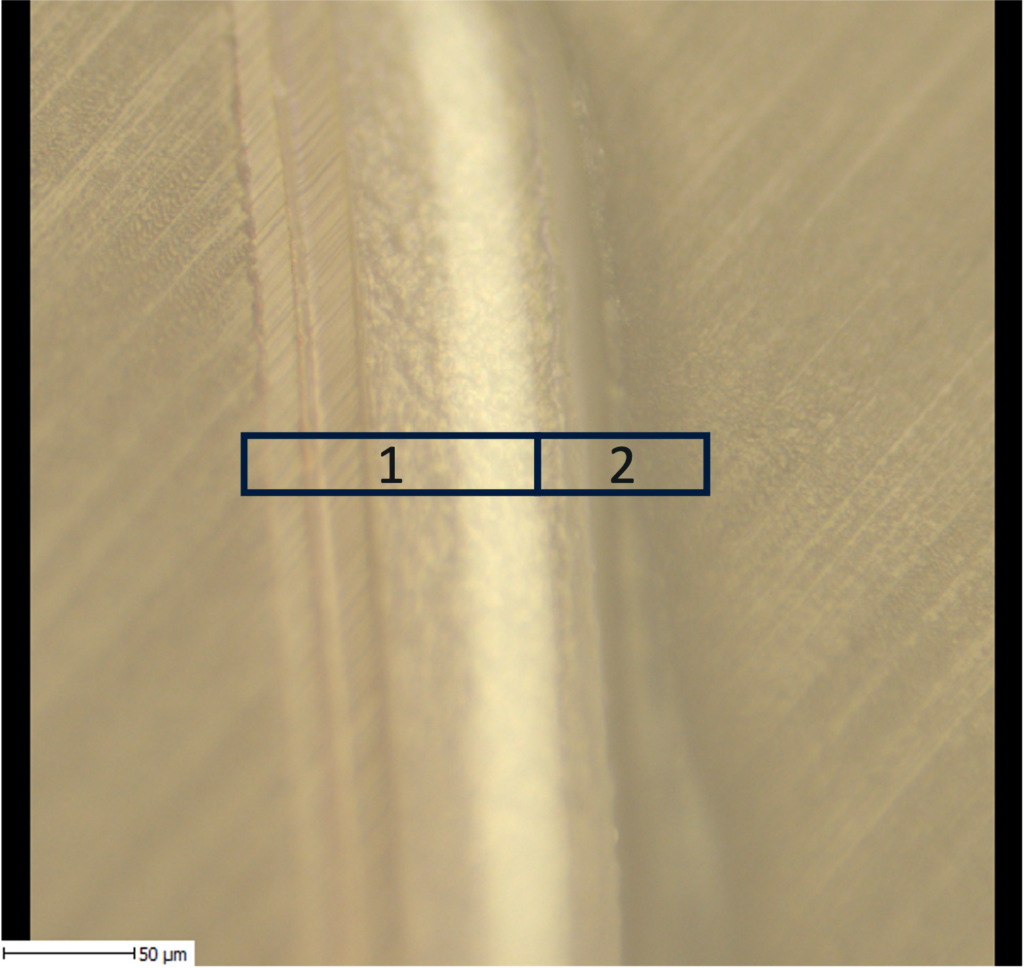

In this article, IR PiFM was used to analyze the cross-section of a packaging material utilized in microwave-compatible ready-to-eat rice products. The packaging material was cut, embedded in UV-curable resin, and microtomed to prepare a flat cross-section for analysis. Figure 1 displays the optical image of the embedded material, which has a thickness of approximately 125 µm.

Two measurements were required to cover the entire width of the material, as the scanner has a maximum range of 120 µm. The following discussion focuses on the results obtained in the larger area (region 1, 116 µm × 20 µm).

Figure 1. Optical view of the cross-sectioned sample. In order to analyze the full width of the sample, two separate measurements had to be made. In this note, we will focus on the results obtained in the region labeled 1, which measures 116 µm × 20 µm. Image Credit: Molecular Vista

Download the full PDF to keep reading

This information has been sourced, reviewed, and adapted from materials provided by Molecular Vista.

For more information on this source, please visit Molecular Vista.