When using a measurement microscope, users can measure the size and dimensions of sample features in both two and three dimensions, which is important for inspection, quality control (QC), failure analysis, and research and development (R&D). However, it is crucial to assess microscope performance, flexibility, and ease of use to choose the correct microscope for a task.

Today, measurements are usually made digitally, i.e., using a microscope with a camera and software that display images on a monitor, rather than via an eyepiece reticule. This has led to better repeatability and precision. Research teams can achieve faster, more reliable sample analysis by selecting the appropriate measurement microscope.

Why Use a Measurement Microscope?

Measurement microscopes are vital tools for analyzing the dimensions of features across a wide range of samples. They play a critical role in inspection, quality control (QC), failure analysis, and R&D in many different industries. Choosing the correct measurement microscope depends on a user’s specific needs, including the types of samples analyzed, the applications performed, optical performance, and camera resolution.

Modern measurement microscopes have digital capabilities and are composed of a camera, a monitor to display images, and software that allows users to precisely and automatically measure and analyze samples.

More information about how to choose the most appropriate measurement microscope is described below.

How to Select a Measurement Microscope

Sample Type, Size, and Features of Interest

Before selecting a measurement microscope, a user should understand the type of sample to be imaged and the features or structures to be analyzed. Depending on whether sample surfaces or internal features are to be measured, users may require a specific type of microscope. In addition, sample preparation is critical for measuring internal structures.

Surface features may protrude significantly above the surface and are often 3D, so it is advantageous to have a microscope with high resolution and a large depth of field. Sample preparation is generally not necessary.

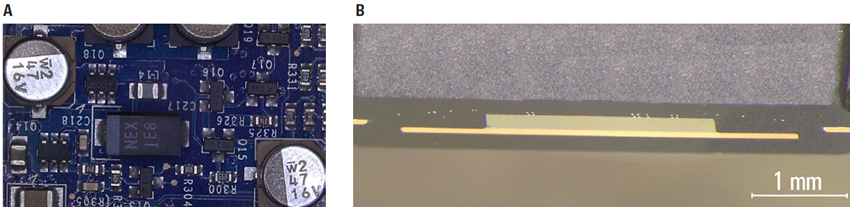

When analyzing internal structures, samples are typically opaque, so a cross-section must be prepared. Preparing the cross-section involves cutting, grinding, and polishing.1 Examples can be seen in electronics, such as printed circuit boards (PCBs) and assemblies (PCBAs), and integrated circuits (ICs) (Figure 1). A microscope with higher resolution is often needed because the internal structure can be small.

Figure 1. Shown here are examples where A) surface features on a PCB sample and B) internal structures in a cross-sectioned IC chip could be measured. Image Credit: Leica Microsystems GmbH

Applications

Measurement microscopes are required for a variety of applications, commonly including inspection, QC, failure analysis, and R&D.

Inspection and QC require reliable, accurate measurements to verify product dimensions, identify defects, and ensure consistency throughout the manufacturing process. It is essential for these processes, to have a microscope with the ability to quickly move from seeing an overview of sample regions to visualizing finer details reliably and precisely.

Failure analysis involves investigating the integrity of components and materials, as well as the causes of failures. A microscope can be used to analyze defects, cracks, or wear at both the microscopic and macroscopic scales.

R&D often investigates poorly understood or complex sample features or structures. This often takes place at the microscale during the development of new components and materials, or even new production processes. It is important that the microscope used for measuring is reliable, flexible, and accurate.

Performance

A measurement microscope’s performance determines how clearly it can resolve fine details and how precisely it can measure sample features or structures. Key factors for optimal performance include digital and optical resolution, correction of optical aberrations, and flatness (planarity).

Resolution

Resolution refers to a microscope's ability to distinguish fine details, such as the separation between two closely spaced thin lines or small points. Good resolution is essential for precise measurement tasks. The resolution of a measurement microscope depends on three key aspects: the numerical aperture (NA) of the optics, the lighting and contrast method used, and the digital camera pixel size.2,3 A larger NA value correlates with better resolution; higher magnification objective lenses generally have higher NA values. Resolution is also affected by the wavelength of light, but white light with an average wavelength of 550 nm is typically used.

Camera Pixel Size

In digital microscopy, the pixel size of the camera is crucial to resolution.2 The majority of digital microscope cameras have pixel sizes in the 1 to 5 μm range. At higher magnification values of more than two times zoom, the microscope system’s resolution is determined by the numerical aperture and light wavelength.

At lower magnification values (less than 2x zoom), the numerical aperture is usually small, and the resolution of camera sensors will start to fall short of the optical resolution (numerical aperture and light wavelength). The camera sensor will likely determine the microscope system resolution at low magnification. Smaller pixels enable higher image resolution on an electronic display, especially at lower magnification values.

Optical Quality and Aberrations

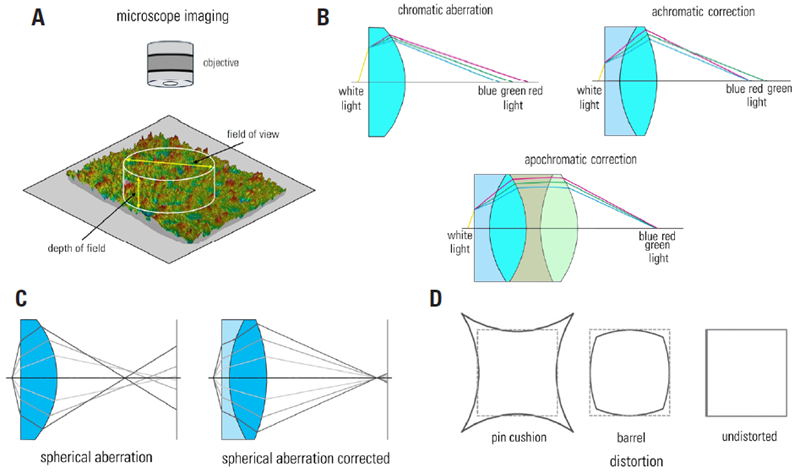

The microscope optics must be corrected for spherical or chromatic aberrations and planarity (Figure 2), which may impact the accuracy of the measurements.4 Aberrations can seriously distort the image, and planarity makes the image appear flat across the field of view. To achieve accurate measurements, aberration correction and planarity are crucial.

Within Leica's standards for correcting microscope objectives, there are both achromats and apochromats.5 Achromats have an achromatic correction where both the red and blue wavelengths of light (within white light) have an absolute value of focus of less than two times the depth of field (DOF) of the objective.6

Apochromats have an apochromatic correction where the red, green, and blue wavelengths of light have an absolute value of focus of less than one time of that of the DOF. The planarity (also called field flatness) for the field of view (FOV) of achromats and apochromats is up to 25 mm. Figure 2A shows the DOF and FOV of an objective, and Figure 2B shows the correction for chromatic aberration.

Figure 2. Some aberrations which must be corrected for optical microscope imaging: A) diagram showing the field of view (FOV) and depth of field (DOF) of a microscope objective imaging a sample; B) achromatic and apochromatic correction demonstrated with ray tracing of white light passing through lenses; C) spherical correction also clarified with ray tracing; and D) illustration explaining the distortion possible with optical lenses which also is corrected. Image Credit: Leica Microsystems GmbH

Choosing the Right Kind of Microscope

Stereo, Compound, or Digital Microscope

Measurement microscopes use either fixed (compound) or zoom (stereo) optics (Figure 3).7,8 Unlike conventional stereo and compound microscopes, digital microscopes do not have eyepieces, so the image is detected by an integrated camera and displayed on a monitor.9 Digital microscopes can use either fixed or zoom optics.

Both stereo microscopes and digital microscopes with zoom optics offer larger fields of view, but low resolution. Conversely, compound microscopes and digital microscopes with fixed optics offer higher resolution, but smaller fields of view. Today, most users use digital imaging and software to measure and analyze samples. A range of microscopes from Leica Microsystems, including stereo, compound, and digital microscopes, as well as digital microscope cameras and software, perform well as measurement microscopes.

Figure 3. A Leica A) stereo, B) compound, and C) digital microscope are shown above. Image Credit: Leica Microsystems GmbH

Important Factors to Consider

To decide what type of microscope should be used for a given task, there are some factors that should be considered beforehand:

- The type, size, and form (solid, liquid, etc.) of the sample that will be measured and analyzed, and any special considerations, such as environmental or electrical conditions needed for imaging, like temperature or humidity.

- Applications for which measurements are needed.

- The sizes of sample features that must be resolved for measurements.

- Any special illumination or contrast is required to see features clearly.10, 11, 12, 13

- Microscope setup and software for practical measurement, particularly if multiple measurements are required.

For many sample types and applications, whether inspection, QC, failure analysis, or R&D, the ease of use, flexibility, and versatility of the microscope are paramount. A user-friendly setup with customizable interfaces makes systems simpler, reducing the time required to learn the software and reducing measurement errors. Flexible, versatile, and easy-to-use measurement microscopes improve user comfort and efficiency while measuring, thereby enabling accurate, reliable data.

It is also important to consider how the microscope performs in regard to sample, positioning, illumination, and resolution. The resolution, contrast, and illumination should allow the sample of interest to be clearly visualized and easily resolved.

Positioning the sample for taking measurements sometimes requires a stage with high-precision horizontal and vertical (x, y, and z) adjustments to ensure features and structures are measured precisely and reliably.

Microscope calibration is also crucial when taking measurements.14 Calibration should be performed with a reference or standard after the microscope is set up and checked regularly to ensure that reliable data is acquired and standards are complied with.

Examples of Measurement Microscopes

Leica measurement microscope solutions have been used previously in inspection, QC, failure analysis, and R&D settings, as outlined below.

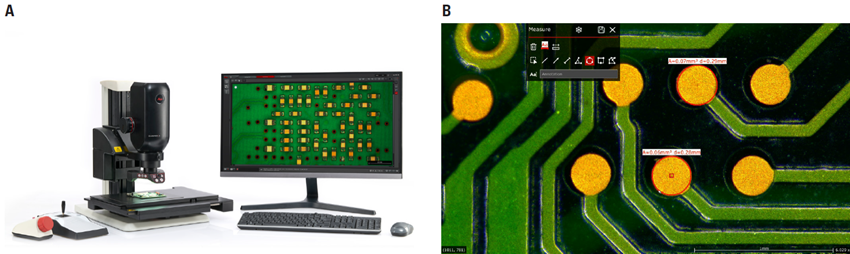

Basic 2D Measurements

If it is only required to take basic 2D measurements, such as the dimensions of a sample’s structures and features, angles between intersecting structures, the area of a geometrical shape, or the distance between given features or structures, a Leica microscope using the Enersight software is an optimal solution (Figure 4). Such a setup can be operated without a computer.

Figure 4. A) Leica measurement microscope with Enersight for basic 2D measurements and B) length and area measurements made on a PCB. Image Credit: Leica Microsystems GmbH

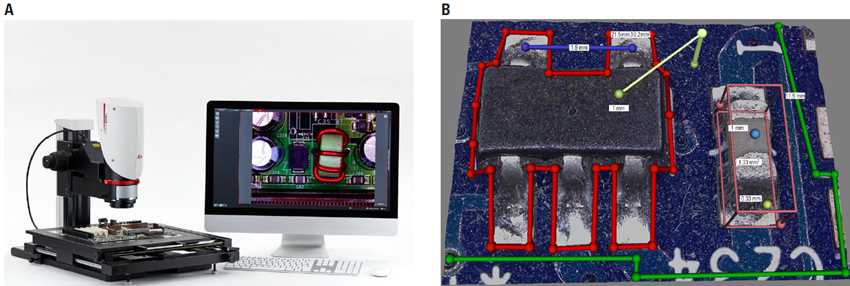

Advanced 3D Measurements

A Leica microscope with LAS X software is recommended for cases requiring advanced 3D measurements (Figure 5). Lateral and vertical dimensions can be measured, as can more advanced measurements. If an encoded motorized stage or column is used, height can also be measured.

Figure 5. A) Leica measurement microscope with LAS X for advanced 3D measurements and B) length, area, and height measurements made on components of a PCB. Image Credit: Leica Microsystems GmbH

Automated Measurements

In some instances, it is most practical to take automated measurements, so a Leica microscope with an automated optics, column, and stage setup, controlled by LAS X software, is a good option (Figure 6).

This automated solution streamlines sample measurement and analysis, minimizing user intervention and errors while improving the reproducibility of results and the efficiency of workflows. It is particularly beneficial in industrial and research applications that require high-throughput and repetitive analysis of complex samples, such as the metal alloy microstructure analysis of grains, phases, and inclusions.

Figure 6. A Leica measurement microscope with LAS X for automated measurements concerning the analysis of steel alloy. Image Credit: Leica Microsystems GmbH

Summary and Conclusions

Measurement microscopes are useful for analyzing a variety of samples within quality control, failure analysis, research and development, and other applications. Several factors must be considered when choosing a measurement microscope, including the types of samples to be analyzed, the microscope’s applications, and its system performance in terms of resolution and versatility, to ensure the appropriate system is selected.

Leica has a wide range of stereo, compound, and digital microscopes, which enable users to efficiently make precise measurements, such as distances, areas, angles, and heights, of sample features for a variety of applications and needs.

Acknowledgments

Produced using materials originally authored by David Barbero, James DeRose, and Nicholas Baker from Leica Microsystems.

References

- Barbero, D.R. and DeRose, J. (2023). Quality Control via Cross Sections of PCBs, PCBAs, ICs, and Batteries. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/applied/cross-section-analysis-for-electronics-manufacturing/.

- DeRose, J. and Doppler, M. (2023). Understanding Clearly the Magnification of Microscopy. Leica Microsystems. (online) Available at: https://www.leica-microsystems.com/science-lab/applied/understanding-clearly-the-magnification-of-microscopy/.

- Wilson, M., DeRose, J. and Greb, C. (2016). Microscope Resolution: Concepts, Factors and Calculation. Leica Microsystems. (online) Available at: https://www.leica-microsystems.com/science-lab/life-science/microscope-resolution-concepts-factors-and-calculation/.

- Wilson, M. (2017). Eyepieces, Objectives and Optical Aberrations. Leica Microsystems. (online) Available at: https://www.leica-microsystems.com/science-lab/microscopy-basics/eyepieces-objectives-and-optical-aberrations/.

- Leica Microsystems. (2024). Objective Classes. (online) Available at: https://www.leica-microsystems.com/products/microscope-accessories/microscope-objective-lens/objective-classes/.

- Rottermann, R. and Bauer, P. (2010). Depth of Field in Microscopy. Leica Microsystems. (online) Available at: https://www.leica-microsystems.com/science-lab/microscopy-basics/depth-of-field-in-microscopy/.

- Rühl, H. (2012). Optical Microscopes – Some Basics. Leica Microsystems. (online) Available at: https://www.leica-microsystems.com/science-lab/microscopy-basics/optical-microscopes-some-basics/.

- Ippel, E., et al. (2023). Key Factors to Consider When Selecting a Stereo Microscope. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/applied/key-factors-to-consider-when-selecting-a-stereo-microscope/.

- DeRose, J. (2023). Digital Inspection Microscope for Industrial Applications. Leica Microsystems. (online) Available at: https://www.leica-microsystems.com/science-lab/applied/digital-inspection-microscope-for-industrial-applications/.

- DeRose, J. and Doppler, M. (2023). Microscope Illumination for Industrial Applications. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/applied/microscope-illumination-for-industrial-applications/.

- DeRose, J. and Barbero, D.R. (2023). Rapid Semiconductor Inspection with Microscope Contrast Methods. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/applied/rapid-semiconductor-inspection-with-microscope-contrast-methods/.

- DeRose, J., Saini, R. and Scheffler, K. (2024). 6-Inch Wafer Inspection Microscope for Reliably Observing Small Height Differences. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/applied/6-inch-wafer-inspection-microscope-for-reliably-observing-small-height-differences/.

- Barbero, D.R., DeRose, J. and Scheffler, K. (2024). Visualizing Photoresist Residue and Organic Contamination on Wafers. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/applied/visualizing-photoresist-residue-and-organic-contamination-on-wafers/.

- Barbero, D.R., DeRose, J. and Baker, N. (2025). Microscope Calibration for Measurements: Why and How You Should Do It. (online) Leica Microsystems. Available at: https://www.leica-microsystems.com/science-lab/industrial/microscope-calibration-for-measurements-why-and-how-you-should-do-it/.

This information has been sourced, reviewed and adapted from materials provided by Leica Microsystems GmbH.

For more information on this source, please visit Leica Microsystems GmbH.