Sponsored by RETSCH GmbHReviewed by Emily MageeFeb 17 2026

Quality control in the mining industry is essential for efficient resource extraction, compliance with increasingly stringent regulations, and sound economic decision-making.

It is important that mining laboratories deliver accurate, reproducible analytical results while routinely processing large, highly abrasive, and heterogeneous materials.

Reliable sample preparation is key to ensuring that analytical data truly represents the ore body or processed material. This may include crushing, splitting, fine grinding, and sieving.

Growing environmental expectations continue to push the mining sector toward more circular material strategies. For example, while mine waste and tailings were historically treated as liabilities, these are now increasingly considered and assessed as potential raw materials for new applications or secondary resources.

Current research has highlighted that advanced processing and milling technologies play a role in converting these types of materials into valuable products.

RETSCH Jaw Crusher BB 600. Image Credit: RETSCH

Pre-Crushing Solutions for Hard, Abrasive, and Heterogeneous Materials

Mining samples often contain exceptionally hard, brittle, or mixed mineral components, requiring wear-resistant yet powerful crushing solutions.

- Jaw crushers offer dependable primary size reduction, with adjustable gap widths for controlled final particle size.

Retsch offers a diverse portfolio of jaw crushers suitable for laboratory- and pilot-scale mining applications, combining robust construction, ease of operation, and straightforward cleaning.

The company’s portfolio can accommodate a wide range of sample volumes, feed sizes, and throughput requirements.

RETSCH Jaw Crusher BB 250. Image Credit: RETSCH

For instance, the benchtop BB 50 is suitable for routine laboratory preparation. It accepts feed sizes up to 40 mm and can reduce material to as fine as 0.5 mm.

The BB 600 supports high-capacity sample preparation in mining operations, accommodating process feed sizes up to 350 × 170 mm and offering a throughput of up to 3500 kg per hour.

Intermediate models like the BB 250 and BB 400 provide sufficient feed capacity and a front-door design that enables straightforward cleaning. This is a key benefit when processing several different ore types.

The BB 500 is designed to support applications requiring fine final particle sizes down to 0.5 mm and high throughput, as well as offering optional heavy metal-free grinding tools.

Jaw materials such as tungsten carbide and zirconium oxide minimize wear and prevent trace metal contamination, making them ideal for use with highly abrasive ores.

Operators can tailor the final particle size to downstream analytical requirements by adjusting the jaw gap.

In daily laboratory practice, a two-step crushing approach often reduces total processing time compared to forcing coarse particles directly through a narrow gap. This is achieved first with a larger gap and followed by a finer setting.

200 g Iron ore in BB 50 with a gap of 0.1 mm in 1 min. Image Credit: RETSCH

200 kg/h in BB 500 with a gap of 0.1 mm in 2.5 min. Image Credit: RETSCH

10 kg Diorite in BB 300 with a gap of 1 mm in 1.5 min. Image Credit: RETSCH

20 kg Mangan ore in BB 300 with a gap of 10 mm and 1 mm in 3 min. Image Credit: RETSCH

Cyclone Integration: Dust-Free Discharge and Maximum Recovery

Cyclone separators reduce dust emissions, limit heat buildup, and ensure reliable material discharge emissions, considerably enhancing crushing and milling efficiency in mining laboratories.

These devices facilitate almost total sample recovery while allowing the flexible placement of collection containers up to 30 l in volume. Reduced dust exposure and cleaner air also directly contribute to safer working conditions while improving compliance with occupational health standards.

Cyclone suction units are available for the BB 50, BB 250, BB 400, and BB 500 enabling clean, efficient sample preparation workflows when using these instruments.

RETSCH Jaw Crusher BB 50 with cyclone. Image Credit: RETSCH

Accurate Subsampling and Efficient Particle-Size Analysis

Up to 60 l of sample material can be fed to the hopper of the sample divider PT 300. Image Credit: RETSCH

Representative sample division and accurate particle-size classification are essential for ensuring reliable analytical outcomes after a sample has been crushed.

Improper sample splitting during mining quality control continues to be one of the most widely encountered sources of analytical error. The PT 300 sample splitter has been designed to accommodate volumes of up to 60 l in a single operation, enabling the representative division of bulk mining samples.

Manual splitting methods typically require repeated handling, exposing operators to dust. The rotating PT 300 processes large sample volumes in one pass and uses a vibratory chute to ensure uniform material flow.

The division process generally takes less than 10 minutes and produces reproducible, statistically valid subsamples.

The PT 300 provides a reliable foundation for mining laboratories routinely handling ore, tailings, or aggregate samples in the 20-60 kg range, enabling fine grinding and analysis while reducing operator variability and effort.

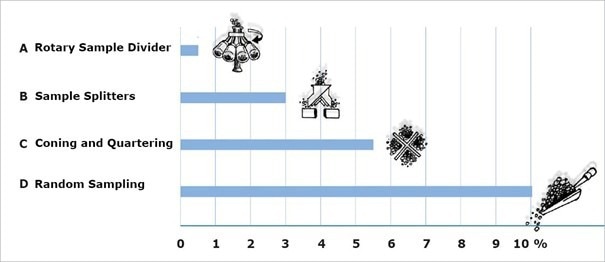

Bulk material, feed size < 5 mm. The diagram shows qualitative variations among part samples for various methods of sampling and sample division. Image Credit: RETSCH

The Vibratory Sieving Machine AS 450 controls has been engineered to enable high-capacity particle size analysis under challenging conditions. Its three-dimensional vibratory motion combines circular motion with vertical acceleration, maintaining a consistent amplitude of up to 2.2 mm even under heavy loads of up to 25 kg.

Integrated CET technology ensures that material is uniformly distributed, irrespective of sample weight. The AS 450 control delivers significantly lower oversize rates and superior reproducibility compared with traditional electromagnetic or imbalance-driven shakers, supporting efficient laboratory workflows by reducing the need for manual resieving.

RETSCH Vibratory Sieve Shaker AS 450 control. Image Credit: RETSCH

Air jet sieving machines are designed for the precise, rapid separation of fine powders below 200 µm. Not only does the generated air stream ensure accurate sieving, but it also effectively deagglomerates electrostatically charged or cohesive particles.

Air jet sieving supports the rapid quality control and process monitoring of ores, tailings, and mineral powders in mining laboratories, without the need for wet dispersion or mechanical agitation.

This approach helps minimize sample loss and contamination, provide reproducible results, and ensure compliance with key particle size specifications for downstream processing.

RETSCH Air Jet Sieving Machines AS 200 jet and AS 200 jet pro. Image Credit: RETSCH

Fine Grinding for High Precision XRF and XRD

XRF, XRD, and similar analytical techniques require the use of extremely fine, homogeneous powders to achieve accurate, reproducible results.

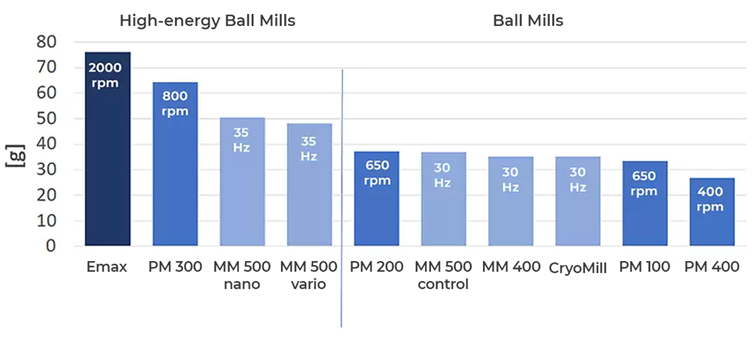

Specialized fine-grinding equipment is needed to achieve this level of preparation for hard, brittle mining materials. Ball mills are commonly used for this purpose, offering both homogenization and efficient size reduction.

Retsch offers a range of mixer mills and planetary ball mills designed to accommodate various analytical requirements and sample quantities.

The Drum Mill TM 300 enables efficient processing for large sample volumes of up to 5 l. Vibratory disc mills are widely used to enable rapid homogenization of mining samples. Models such as the RS 200 and RS 300 also offer reliable preparation for subsequent analysis, depending on sample volume.

RETSCH Mixer Mill MM 400, Planetary Ball Mill PM 100, Vibratory Disc Mills RS 200 and RS 300, and Drum Mill TM 300. Image Credit: RETSCH

Check Out the Interactive Copper Ore Poster Here

10 g Ore in MM 400 in 2 min, < 100 µm. Image Credit: RETSCH

120 g Iron ore in RS 200 in 1 min, < 100 µm. Image Credit: RETSCH

3 kg Iron ore in RS 300 in 12 min, < 100 µm. Image Credit: RETSCH

1 kg Ore in DM 200 in 6 min, < 400 µm. Image Credit: RETSCH

The disc mill DM 200 has been designed to facilitate the fine crushing of highly abrasive materials, including ores and minerals. Long service life and consistent performance are ensured by its wear-resistant grinding tools, which enable particle sizes down to 50 µm.

Laboratories that do not require intermediate sample splitting between pre-crushing and fine grinding can connect jaw crushers such as the BB 50 or BB 250 directly to the DM 200.

When used alongside cyclone units, this setup delivers continuous airflow for sample transport and collection, enabling fine, homogeneous sample preparation in a single batch and streamlining workflows.

RETSCH Combo unit: Jaw Crusher BB 250 and Disc Mill DM 200 with cyclone system. Image Credit: RETSCH

Dust free fine grinding with Jaw Crusher BB 250, Disc Mill DM 200 and Cylcone System

Video Credit: RETSCH

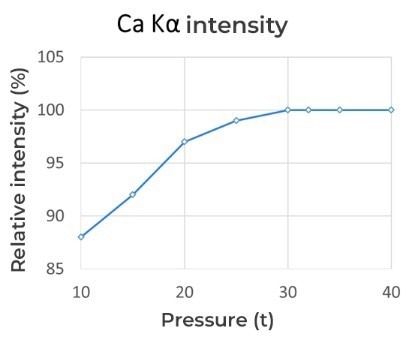

Reliable XRF analysis requires a smooth, flat sample surface. This ensures consistent interaction between X-rays and the sample while also minimizing scattering and signal loss.

There is a risk of uneven surfaces leading to measurement inaccuracies because of the variable distances between the sample and the detector.

The PP 40 pellet press delivers smooth, strong pellets with individually adjustable pressing forces up to 40 tons. Programmable pressing steps ensure pellet stability and support precise, reproducible elemental analysis, even with challenging mining matrices.

A pressure force of 30 tons is sufficient to achieve optimal intensities in the XRF signals, depending on the element being analyzed and the matrix components. Some exceptions require higher pressure forces up to 40 tons, however.

Image Credit: RETSCH

XRD Mill McCrone

XRD analysis is highly sensitive to particle shape, size, and amorphization. The XRD Mill McCrone is designed to meet these requirements, delivering:

- Exceptionally narrow particle size distributions

- Minimal damage to crystal structures

- Friction-based grinding with a total of 48 zirconium oxide elements

- Final fineness below 10 µm, making it ideal for phase identification

RETSCH XRD Mill McCrone. Image Credit: RETSCH

The McCrone mill can be used to prepare minerals, cement, clinker, and related materials with minimal structural disturbance and high reproducibility, supporting reliable mineralogical analysis in materials research and mining.

Research Innovations in Mine Waste Recycling

Mining tailings represent both opportunities for secondary resource recovery and environmental challenges. Current research is increasingly focused on transforming these historically wasted materials into functional products.

The Horizon Europe START Project outlines the processing of tailings rich in tetrahedrite from historic European mines into thermoelectric materials suitable for use in sustainable energy harvesting.

High-energy milling via the Emax is key to this mechanochemical transformation, highlighting the use of advanced grinding technologies in supporting innovation in the recycling of mine waste.

RETSCH High-energy Ball Mill Emax. Image Credit: RETSCH

The Emax delivers the highest energy input of all Ball Mills. Image Credit: RETSCH

Conclusion

Accurate, reproducible sample preparation is essential in modern mining settings. Properly prepared samples are the foundation of reliable mineral analysis, regulatory compliance, and efficient resource use.

Leveraging a comprehensive portfolio of jaw crushers, cyclone systems, sample dividers, disc mills, sieve shakers, and specialized fine-grinding solutions enables mining laboratories to establish a robust, scalable foundation for each stage of the analytical workflow.

These tools are key to supporting precision in current mining applications and more sustainable mining practices in the future.

Acknowledgments

Produced from materials originally authored by RETSCH.

This information has been sourced, reviewed, and adapted from materials provided by RETSCH.

For more information on this source, please visit RETSCH.