|

Among the first instruments plastics molders, extruders, and compounders are likely to consider when outfitting a new lab is a melt-flow indexer or “melt indexer.” Known as an extrusion plastometer in more technical jargon, this apparatus has long been used to determine the melt-flow rate or mass-flow rate (MFR) of virgin and compounded thermoplastic resins. With the increased pressure on plastics processors to comply with quality standards for quality management, more of them are using these instruments to evaluate incoming material and test finished products.

The melt-flow test detailed in the ASTM D1238 and ISO 1133 standards quickly measures one point on the viscosity curve under standard conditions. While the relative simplicity of this test has remained the same, melt indexers have evolved considerably since they appeared in the 1950s. Computerization and automation have reduced operator-to-operator variables, yielding results with greater accuracy and repeatability.

How a Melt Indexer Works

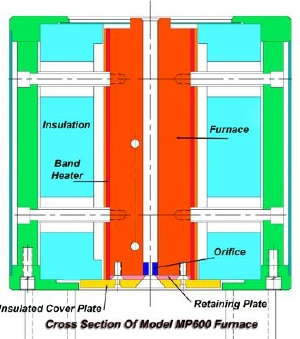

The melt indexer consists of a heated barrel and piston assembly to contain a sample of resin. A specified load (weight) is applied to the piston, and the melted polymer is extruded through a capillary die of specific dimensions.

Figure 1. Tinius Olsen's model MP600 shown in Procedure A configuration

Properties Determined by Melt Flow Indexers

The mass of resin, in grams, that is extruded in 10 minutes equals the MFR, expressed in units of g/10 min. (This value is also commonly called the melt index, MI, or melt-flow index, MFI.) Some instruments can also calculate the shear rate, shear stress, and viscosity in centipoise.

What is Measured During a Melt Flow Test

The basic property measured by the melt flow test is the melt viscosity or flow resistance of the polymer at a particular shear stress (related to the applied load) and temperature. Polymer chains of short length and simple geometry “slide” past one another relatively easily and offer little flow resistance. In contrast, long chains of high molecular weight and more complex structure yield greater flow resistance or viscosity.

The Relationship of Mass Flow Rate to other Properties

The MFR, then, is an indicator of average molecular weight and is inversely related to it. A resin with an MFR of 50 g/10 min indicates a lower molecular weight than one with an MFR of 10 g/10 min. While a higher MFR material may be easier to process, physical properties related to molecular weight, such as impact resistance, are often lower.

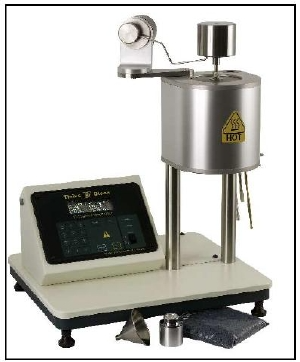

Figure 2. Cross-section of melt indexer furnace.

Mass Flow Rate or MFR and Quality Control

Thus, MFR is commonly used as a material-acceptance specification by processors and also as a means of comparing resins from different vendors. It also has many uses in quality control. Not only can variations in polymerization and compounding affect MFR of incoming resin, but it is also a valuable indicator of resin degradation caused by transport or storage conditions or improper drying. Regular MFR testing after molding or extrusion can help pinpoint improper processing conditions. It also provides a simple indicator of how addition of in-plant regrind or post-consumer reclaim may affect the virgin resin’s processability and end-use performance.

Case Study – Using MFR for Quality Control

As an example of an actual case of how this information can be used: An injection molded polycarbonate part was found to crack when dropped. The virgin resin had an MFR of 28.5 g/10min. A sample from a known “good” lot of parts was ground up and tested in a melt indexer. It had an MFR of 27, well within established tolerances (±30%). But a “problem” part showed an MFR of 90. From this evidence, it was discovered that the “bad” lot contained a large amount of regrind that had been thermally degraded in processing.

ASTM 1238 vs ISO 1133

ASTM 1238 and the ISO 1133 test methods are “technically equivalent” but there are some minor differences. The way the test is run is different, as are some technical specifications, which can lead to different results.

Test Procedure A

Both ASTM 1238 and ISO 1133 offer two variations of the standard melt-flow test: Procedure A and Procedure B. Procedure A describes a basic manual melt indexer. It involves making “cuts” of the extrudate at timed intervals as it exits the extrusion die at a defined test load and temperature. The “cuts” are weighed on an analytical balance to determine the average mass and this value is extrapolated to the mass that would be extruded in 10 minutes-the MFR.

Figure 3. Tinius Olsen model MP600 shown in Procedure B configuration

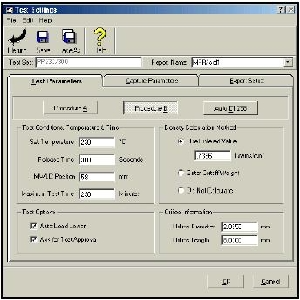

Figure 4. Screenshot of equipment set-up screen from EP600 software

Melt Index Test Load Ranges

Test loads range from 1.2 to 21.6 kg to permit measuring materials ranging from very low to very high viscosity (more viscous melts require more weight to force them through the die). The load and temperature to be used are determined by the material and the test method.

Automated Cutters on Melt Indexers

All new melt indexers today are provided with automatic timers, and some have automatic extrudate cutters. Although the latter works well with some plastics, some resin melts are sticky or difficult to manipulate to obtain a clean-cut and in many cases, automatic cutters cannot match the human hand.

Calculating MFR Using Test Procedure B

Procedure B testing is simpler in that there is no extrudate cutting or weighing because it is volumetric. The volume of the resin extruded is obtained from the geometry of the barrel and distance of piston travel over a measured time period. This determines the melt volume rate (MVR) in cc/10 min. From this value and the resin’s known melt density, the MFR can be calculated automatically. With Procedure B testing, the operator simply loads the barrel with resin, starts the test, and the instrument calculates the results.

Advantages of Test Procedure B

This is the first advantage over basic Procedure A instruments; these units measure 20, 30, or 40 measurement points in one test run and statistically calculate which results are within the norm and which are outside the norm due to an air bubble or other impurities. The second advantage is that there is less user interference. Results, then, are generally more accurate and more reproducible.

On the other hand, Procedure B testing requires an accurate value for the resin melt density at the test temperature. Such values are available in published literature, for example, typical values for “generic” PE and PP are cited in the ASTM 1238 standard. However, most sources consider it more accurate to measure the actual melt density of the specific resin being tested. This is done by combining elements of Procedure A and Procedure B in a single test run so as to obtain data for both weight and volume-hence, density. Today’s melt indexers for Procedure B can be used to perform both tests.

Test Procedure A vs Procedure B

There is no general consensus as to which procedure is best. Some recommend Procedure A for most processors since it tests the ‘bulk property’ of the material and doesn’t presume that you know or trust a stated melt-density value for the actual resin. Others view Procedure A as best for operators that use a broad range of materials and additive packages whereas they see Procedure B as best suited to labs that make frequent measurements of the same type of material with a known melt density.

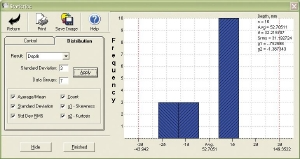

Figure 5. Screenshot from EP600 software showing basic SPC capabilities

Multi-Weight Melt Flow Test

There is also a multi-weight melt flow test, which unlike standard Method A and Method B, provides more than one measurement on a single charge under two or three different load conditions (using different weights).

The multi-weight test is referenced under ASTM D1238 as a variation of the melt-flow test, but instrument suppliers are working to write a separate standard for this test.

Multi-Weight Melt Flow Test Instruments

Several suppliers offer the multi-weight capability. In an instrument that can calculate the shear rate and viscosity in addition to MFR, multi-weight measurement provides the equivalent of a “poor man’s capillary rheometer,” suppliers say.

Most suppliers agree that multi-weight instruments are mainly suitable for use by resin producers or compounders who want to provide their customers with more information on how a material will behave.

Features of Melt Flow Indexers

Price differences reflect mainly options. Temperature controls may include an automatic preheat phase as either standard or optional. Digital encoders are available to measure piston travel for Procedure B with much higher precision than the older optical technology using photocells or mechanical switches. Motorized lifting and lowering the weight onto the piston is another option.

Other new options include automatic compaction of the resin pellets before heating. Manually tamping down the material with a rod can account for as much as 10% variation in MFR results, and this variation is reportedly eliminated by a motor driven rod.

Modular Design of Melt Flow Indexers

Some suppliers take a modular or building-block approach, which permits adding capabilities to a basic unit after the purchase. For example, the initial purchase of a rudimentary Procedure A machine and the subsequent additions of an encoder switch, motorized weight lifting device, cleaning and purging accessories and pc based software means that this rudimentary machine can be converted into a semi-automatic system that operates at the click of a single mouse click.

Melt Indexer Ovens

Besides option packages, price differences among melt indexers also have to do with the way the units are manufactured and calibrated. While technical specs are prescribed by ASTM, some suppliers just meet them, while others exceed them. A key point when buying a melt indexer is that temperature control must be absolutely stable. For example, some units have two heating elements around the barrel, while others only have one. Also, some have smaller ovens (the cylindrical block that surrounds the barrel), which means insulation and heat retention are not as good. A bigger oven around the barrel will allow the temperature to stabilize more quickly.

Figure 6. Model MP600 shown in Procedure B configuration with a motorized weight lowering platform for semi-automatic operation.

Calibration of Melt Indexers

Suppliers also say calibration is critical to the proper use of a melt indexer, and they recommend that buyers make sure their vendor offers calibration services. Calibration requires checking the temperature inside the barrel at a specific point above the die, and also confirming the dimensions of the barrel, piston, and die.

The Importance of Cleaning Melt Flow Indexers

Finally, the die, piston, and barrel must be easily cleanable. Cleanliness is the heart of good melt indexer practice since old polymer left in a barrel or die will degrade and cause large variations in MFRs.

Figure 7. Model MP600 shown with lowered weight platform and pneumatic purge and pneumatic cleaning pistons for simplified rapid testing and cleaning.

|