It is important that silicon substrates for solar cell applications meet precise technical requirements. On adding surface texture, the light-gathering efficiency is improved, but for highly textured surfaces, light scattering occurs and efficiency is significantly reduced. High-quality diamond wires are required to saw wafers and obtain high-quality finished products.

The KLA Tencor-200 Automated 3D Metrology System allows quality control of critical properties, which are:

- Substrate roughness at multiple steps, from highly rough to highly smooth.

- Periodicity and height of saw marks.

- Edge cracks and other defects.

- Wafer bow.

- Height and density of diamond features on saw wires.

Silicon Wafer Inspection

The various types of silicon wafer inspection are:

- Edge inspection.

- Wafer bow.

- Step height.

- Surface roughness.

Edge Inspection

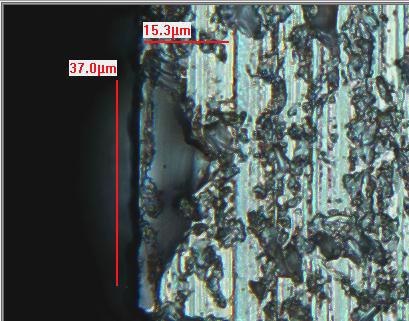

Figure 1 shows a KLA Tencor two-dimensional image of the wafer edge. Length markers are 37 and 15 µm vertically and horizontally, respectively.

Figure 1. KLA Tencor 2D image of a wafer edge.

Wafer Bow

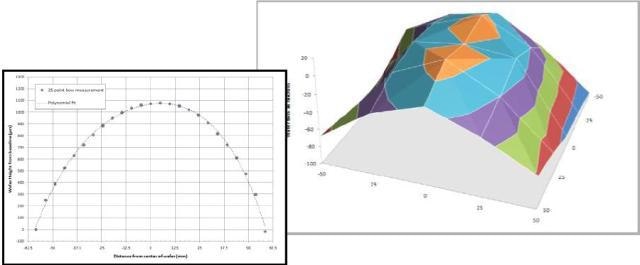

Figure 2 shows the shape of a 5 in. wafer based on two-dimensional or three-dimensional measurements at 25 sites.

Figure 2. Determination of the shape of a 5” wafer based on 2D an 3D measurements at 25 sites.

Step Height

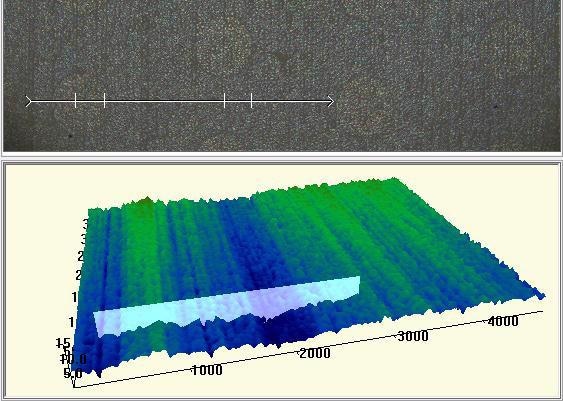

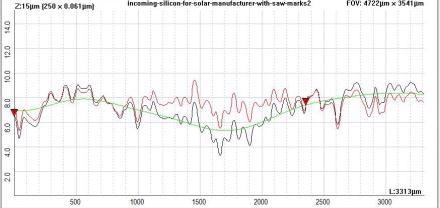

KLA Tencor 2D and 3D images of an incoming substrate (Fig. 3) show saw marks. The distance between cursors is 1215 µm, the height difference between cursors is 3.4 µm and the depth of a single groove is 2.3 to 3.0 µm.

Figure 3. KLA Tencor 2D (top) and 3D (bottom) images of a reference substrate.

Surface Roughness

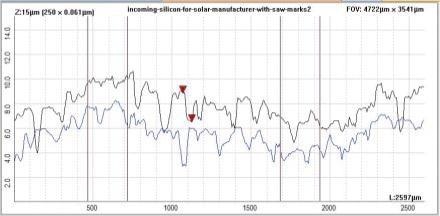

The results obtained from surface roughness analysis are that Ra is 0.95 µm in total or 0.57 µm with waviness correction (Fig. 4).

Figure 4. Results of roughness analysis on the measured wafer.

Diamond Wire Inspection

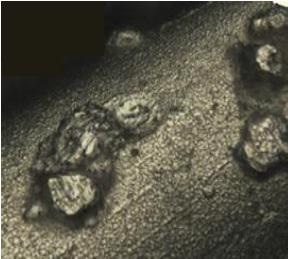

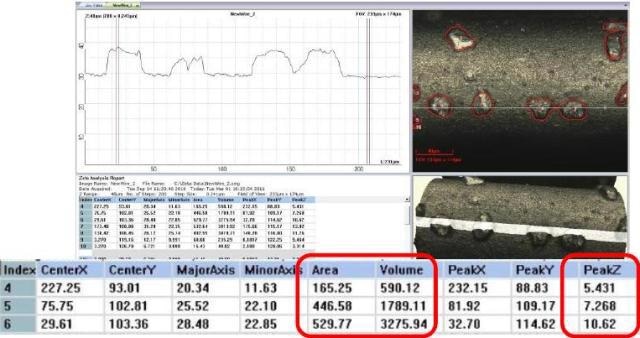

Figure 5 shows KLA Tencor 3D image of a new diamond wire and automated analysis of diamond particles. Each diamond in the field of view is measured for area, volume and height.

Figure 5. KLA Tencor 3D image of a new diamond wire and automated analysis of diamond particles.

Optical Specifications

The optical specifications of the KLA Tencor 200 system are shown in the table below:

Table 1. Optical specifications of the KLA Tencor-200 system.

| Optical Specifications |

| |

5x |

10x |

20x |

50x |

100x |

| Z res(μm) |

5.90 |

1.50 |

0.50 |

0.10 |

0.07 |

| N.A. |

0.15 |

0.30 |

0.45 |

0.80 |

0.90 |

| XY res(μm) |

2.20 |

1.10 |

0.75 |

0.42 |

0.40 |

| FOV 1(μm) |

1920x1440 |

960x720 |

480x360 |

192x144 |

96x72 |

| FOV 2(μm) |

5029x3771 |

2514x1886 |

1257x943 |

503x377 |

251x189 |

| Accuracy ± 2.5% Repeatability ≤ 1.5%(1σ/mean) |

The KLA Tencor-200 System

The KLA Tencor 200 Automated 3D Measurement System enables true color imaging of complex surfaces in less than one minute per site.

The KLA Tencor 3D Software studies two-dimensional or three-dimensional images for the following parameters:

- Step height.

- Surface roughness.

- Feature size, diameter, area and volume.

- Multi-surface analysis for transparent features.

- 3D surface visualization.

- Statistics.

The general applications of the KLA Tencor-200 are:

- Multi-site measurements with statistics.

- Recipe-based measurement definitions.

- Automated data and image export.

The features of the KLA Tencor-200 include the following:

- High-brightness white LED light source.

- XY stage with 200 x 200 mm travel.

- 30 mm total vertical travel.

- Multiple FOV configurations are available.

Figure 6. KLA Tencor-200 system series.

The system includes an Intel Core2 Duo processor with 3GB RAM, 320 GB disk and widescreen LCD monitor.

About KLA Tencor Instruments

KLA Tencor Instruments is a leading provider of precision microstructure and surface measurement systems that enable manufacturers of green-technology and bio-medical products to substantially improve yields and quality control. KLA Tencor advanced metrology solutions provide direct benefit to the production of high-brightness LEDs, solar cells, micro-fluidics/bio-technology and magnetic storage media. The patented Z-Dot™ technology enables manufacturers to quickly and accurately perform 3D measurement of the micron-scale features of these applications, positioning KLA Tencor as a strategic supplier to these high-growth industries.

Metrology solutions from KLA Tencor Instruments are ideally suited to address the measurement challenges confronted by these industries:

- LED.

- Biotechnology.

- Solar.

- Data storage.

This information has been sourced, reviewed and adapted from materials provided by KLA Corporation.

For more information on this source, please visit KLA Corporation.