The new Environics® Series 6123 Ozone Transfer Standard, equipped with a photometer, is the perfect system for individuals looking for a standard in ozone (O3) monitoring and reporting programs.

The S6123 system is a sister unit of the S6103 and uses O3 to perform zero, span, precision and multi-point calibrations automatically.

The S6103 system will be needed if users want to conduct span, zero, precision and multi-point calibrations using O3; however, they can also use the system for hydrocarbons, CO, SO2, NO, NO2 and other target gases.

The S6103 system fulfills or exceeds all U.S. Environmental Protection Agency directives for a level 3 bench or transfer standard.

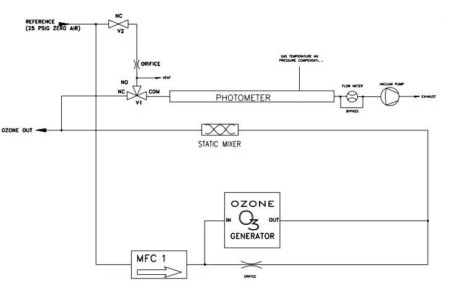

The Environics® Series 6123 includes a solo chassis that supports a single thermal mass flow controller (sized for each customer requirement), a photometer, an ozone generation module, control electronics and an inline static mixer. The unit does not contain any consumables, which makes it easy to maintain.

Image Credit: Environics Inc.

Commands, which are entered from the front panel, are shown on a backlit 4 line by a 20-character liquid crystal display. Besides this, the system can be remotely operated using the RS-232 serial data interface or contact closures, both of which come as standard in the Series 6123.

The Series 6123 also includes a single mass flow controller as standard, and this has been calibrated to a National Institute of Standards and Technology (NIST)-traceable primary standard.

The calibration data includes a comparison of actual versus desired flow across the entire dynamic range of the system with linear interpolation between points. Calibration data is preserved in non-volatile memory and users can update this data with an appropriate standard.

The ozone generator, based on internal ultra-violet (UV), is controlled by temperatures and contains a precision photo-optical feedback circuit to offset lamp aging effects and thus offers a stable generation of O3. A NIST-traceable photometer standard has been used to calibrate the ozone generator at the factory.

Product Features and Benefits

- Thanks to the internally stored mass flow controller calibration data, accuracy is considerably enhanced by a factor of 10, and field recalibration is also streamlined. The mass flow controller has been factory calibrated at 11 points.

- Easy-to-use interactive software with simple language prompts is user friendly, thus decreasing the training time required for technicians and eliminating errors virtually.

- Compensation of ozone generator pressure guarantees a stable and repeatable generation of O3 at pressures other than the original calibration pressure. This is only crucial when the instrument is being utilized without the photometer closed-loop control.

- Internally stored ozone generator calibration data ensures repeatable, linear generation of O3 without photometer control. The performance of the ozone generator fulfills the U.S. EPA criteria for ozone transfer standards. The ozone generator has been factory-calibrated at 3 points (but up to 11 points are also available).

- An automated leak test function is provided to establish whether the instrument has any internal leaks. Leaks are detected depending on pressure decay.

- Using the photometer, an external ozone source can be examined and displayed on the screen. The external ozone is linked to an individual sample port.

- The internal photometer quantifies the true amount of O3 produced, and rectifies any errors with the help of the closed-loop PID control.

Software

- Flow mode: This mode enables users to physically command a required rate of flow either with or without O3.

- Concentration mode: In response to software prompting, users choose O3 concentration and output gas flow (total). The Series 6123 automatically provides concentrations at the specified total flow.

- Generate ozone: This enables users to specify and subsequently create an accurate ozone concentration.

Note: For simple operation, the photometer-loop control can be directly enabled or disabled inside these modes. The unit can also be switched from quantifying the internal to an external source of ozone from these run modes.

- Display: This enables users to track the flow for mass flow controllers. It also provides diagnostic data relating to the ozone oven, photometer and pressure.

- Photometer: This allows users to analyze and display an external ozone source on the screen. It also enables users to regulate the ozone generator when the PID control loop is activated.

Specifications

Performance*

- Accuracy

- Flow repeatability: ±0.05% F.S.O.

- Flow: A setpoint of ±1.0%

- Concentration: A setpoint of ±1.0%

- Warm-up time: 30 minutes

*Specifications of performance are valid only when all mass flow controllers are working from 10% to 100% of full-scale flow. The mass flow controllers are calibrated with a NIST-traceable Primary Flow Standard, where the Reference Pressure used is 760 mm Hg (29.92 in. Hg) and the Reference Temperature is 25°C (77°F).

- Ozone generator

- Concentration range: Ranges from 0.02 to 0.5 ppm at 5 to 10 slpm

- Optional ranges: Ranges from 0.05 to 1.0 ppm at 5 to 10 slpm

- UV photometer

- Precision: 1 ppb

- Noise: ±1 ppb

- Linearity: 0.3% F.S.O.

- Repeatability: ±1 ppb

Mechanical

- Inlets

- Span(s): External 1/4″ Swagelok*

- Balance: External 1/4″ Swagelok*

- Outlet

- One external 1/4″ Swagelok*

- *(or compatible fitting)

- Operating pressures at inlets (flow dependent)

- Nominal: 25 psig (1.72 bar)

- Maximum: 30 psig (2.07bBar)

- Minimum: 20 psig (1.38 bar)

- Wetted surfaces

- Tubing: Teflon®

- Seals: Viton®

- MFC: Stainless Steel

- Operating temperatures: 32°F to 122°F (0° to 50°C)

- Performance temperature range: 59°F to 95°F (15°C to 35°C)

- Weight: 27 lbs

- Dimensions (width x height x depth)

- Rack: 19″ x 7″ x 15″

- Portable: 17″ x 7″ x 15″

- (Optional: 19″ x 7″ x 24″ or 17″ x 7″ x 24″)

Electrical

- Current: 2 A (maximum)

- Voltage: 50/60 Hz, 100 to 250 VAC

Operating Modes

- I/O control (8 inputs and 8 outputs)

- RS-232 serial data interface

- Front panel keypad

Data I/O

- I/O control (8 inputs and 8 outputs)

- RS-232 serial data interface