Automotive and aerospace designers are increasingly using new composite materials and lightweight plastics to reduce weight and thus enhance fuel economy.

To support the adoption of these novel materials, designers are using computer-aided engineering (CAE) modeling techniques to decrease the cost involved in prototype production.

A complete mechanical characterization of new composites and plastics is crucial for effective modeling and safe adoption of these new materials in end products. The most important aspect in modeling precision is reliable input data relating to materials’ mechanical behavior at different temperatures and strain rates.

The HITS-X Series instruments from Shimadzu help analyze the tensile and puncture behavior of materials at testing speeds spanning from 0.0001 to 20 m/second at temperatures that range between −40°C and 150°C.

Key features include:

High test speeds

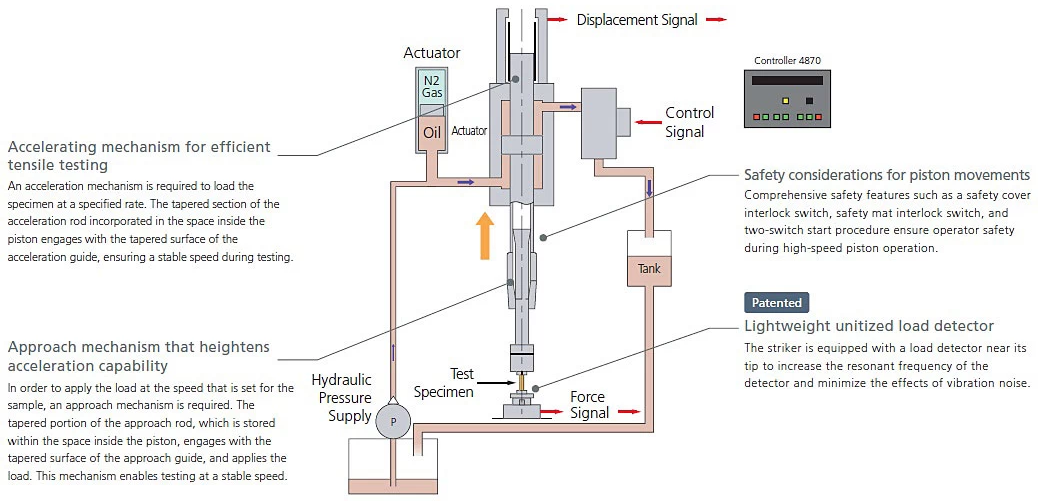

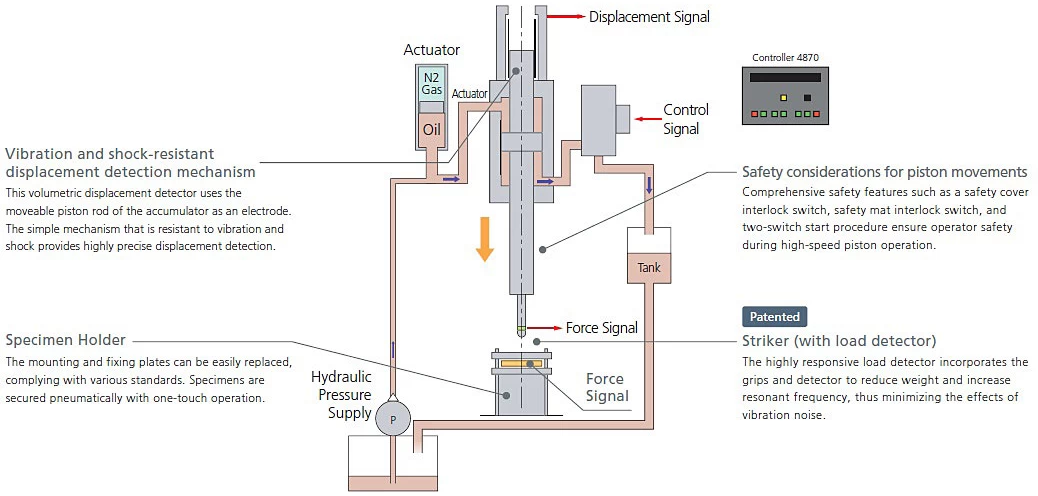

The hydraulic operation allows impact tests to be conducted at any speed between 0.0001 m/s and 20 m/s (72 km/h). It allows a wide range of testing speeds using a single machine.

Designed to minimize the effects of impacts

The HITS Series incorporates various features to minimize the effects of impacts, including metal springs with superior vibration absorption capacity, the displacement detector resistant to vibration and shock, a striker integrated with a load detector (HITS-PX), a load detector integrated with grips (HITS-TX), and a speed reduction and stopping function that combines braking control with hydraulic cushioning (patent pending).

Specialized approach jig (HITS-TX)

Allows target speed to be reached rapidly.

State-of-the-art software

The software provides information such as load-displacement curve, maximum test force, displacement, energy, and inclination. Advanced processing, such as overlaying results from multiple tests or statistical analysis are standard functions.

Environmentally friendly energy-saving design

The HITS Series employs an energy-saving operation system that changes the motor speed and supply pressure for the hydraulic power unit depending on the operating status of the testing machine (patent pending). In addition, the hydraulic power unit is air cooled, so water is not necessary for cooling.

Comprehensive safety features

The HITS Series is equipped with comprehensive safety features, such as a safety cover, safety mat, and dual switch system for starting tests. In addition, for extra safety, the piston uses a mechanism that allows high-speed travel only in the test direction.

High-Speed Tensile Testing Machine HITS-TX System Functions

Image Credit: Shimadzu Scientific Instruments

High-Speed Puncture Impact Testing Machine HITS-PX System Functions (Suitable for ASTM D3763)

Image Credit: Shimadzu Scientific Instruments