ZEISS Xradia CrystalCT is the cutting-edge microCT for deciphering the samples’ crystallographic and microstructural insights.

It is the first to combine the power of computed tomography with the potential to unveil crystallographic grain microstructures, revolutionizing the way polycrystalline materials (such as metals, additive manufacturing, ceramics, and other materials) are studied and directing to broader and unexpected insights into materials research.

- Accomplish non-destructive mapping of grain morphology in 3D

- Attain higher sample representivity to create high-fidelity computational models

- Map larger volumes and a wider array of sample geometries at greater throughput

- Illustrate materials such as metals, alloys and ceramics

- Advance materials classification and discovery through groundbreaking diffraction scanning modes.

Highlights

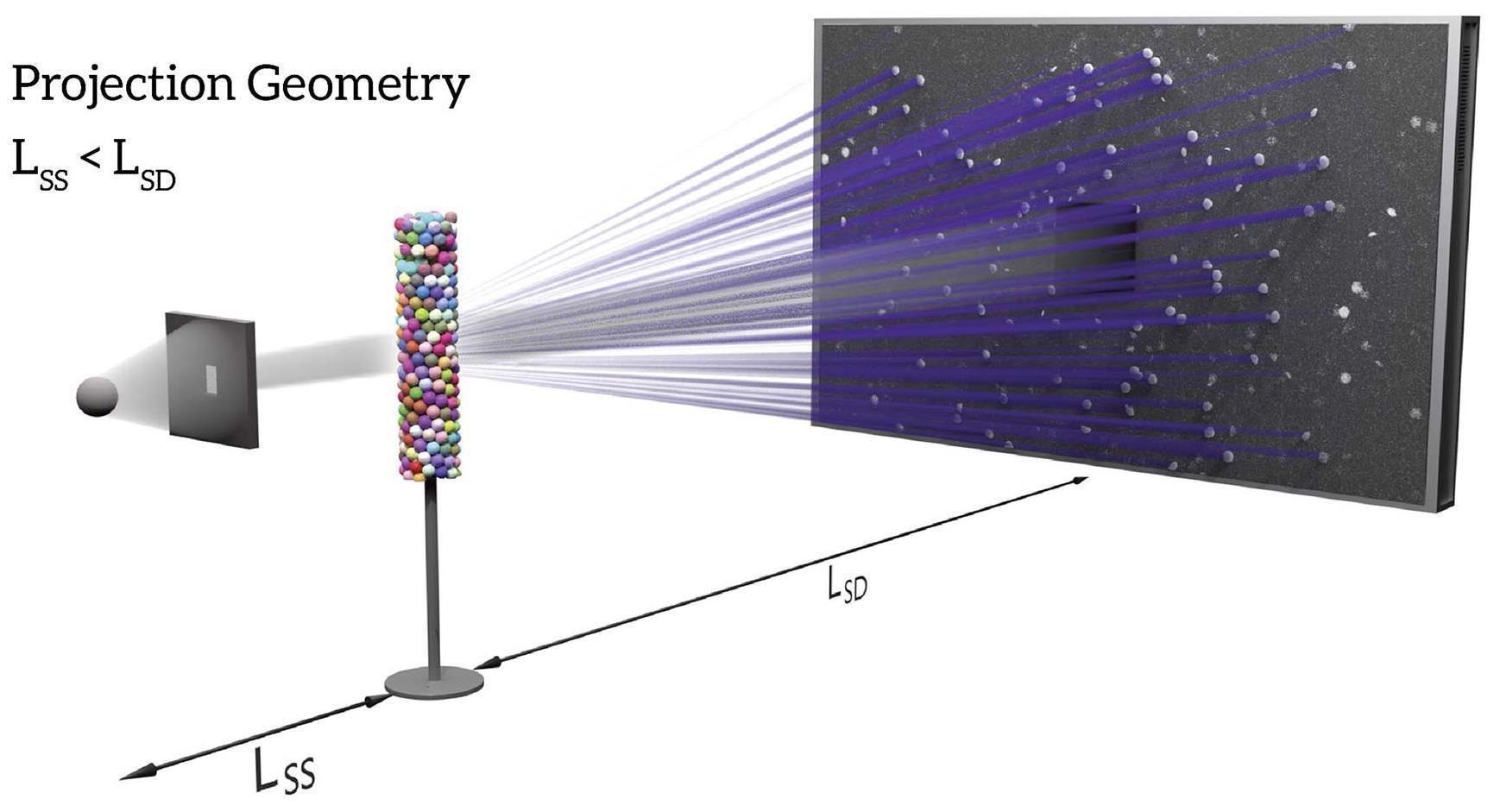

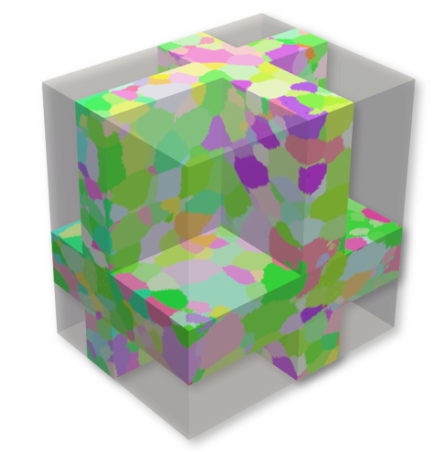

Schematic illustration of CrystalCT projection geometry. CrystalCT delivers dual modalities: absorption contrast tomography (ACT) and diffraction contrast tomography (DCT). Image Credit: Carl Zeiss Microscopy GmbH

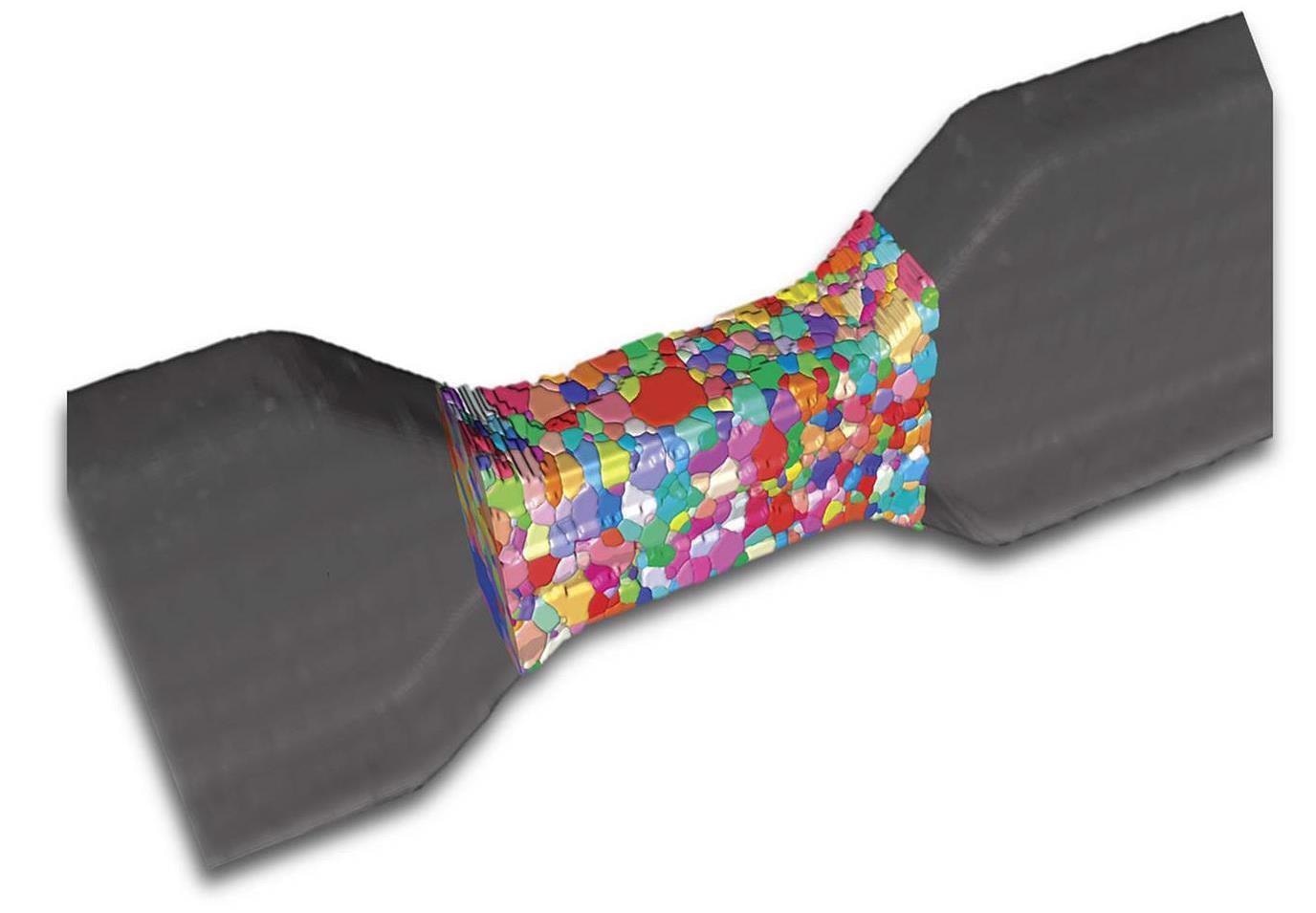

Al-4wt%Cu sample with gauge section dimension of (length) 1.25 mm, (width) 1.0 mm and (thickness) 0.5 mm. Sample scanned using helical phyllotaxis HART. Image Credit: Carl Zeiss Microscopy GmbH

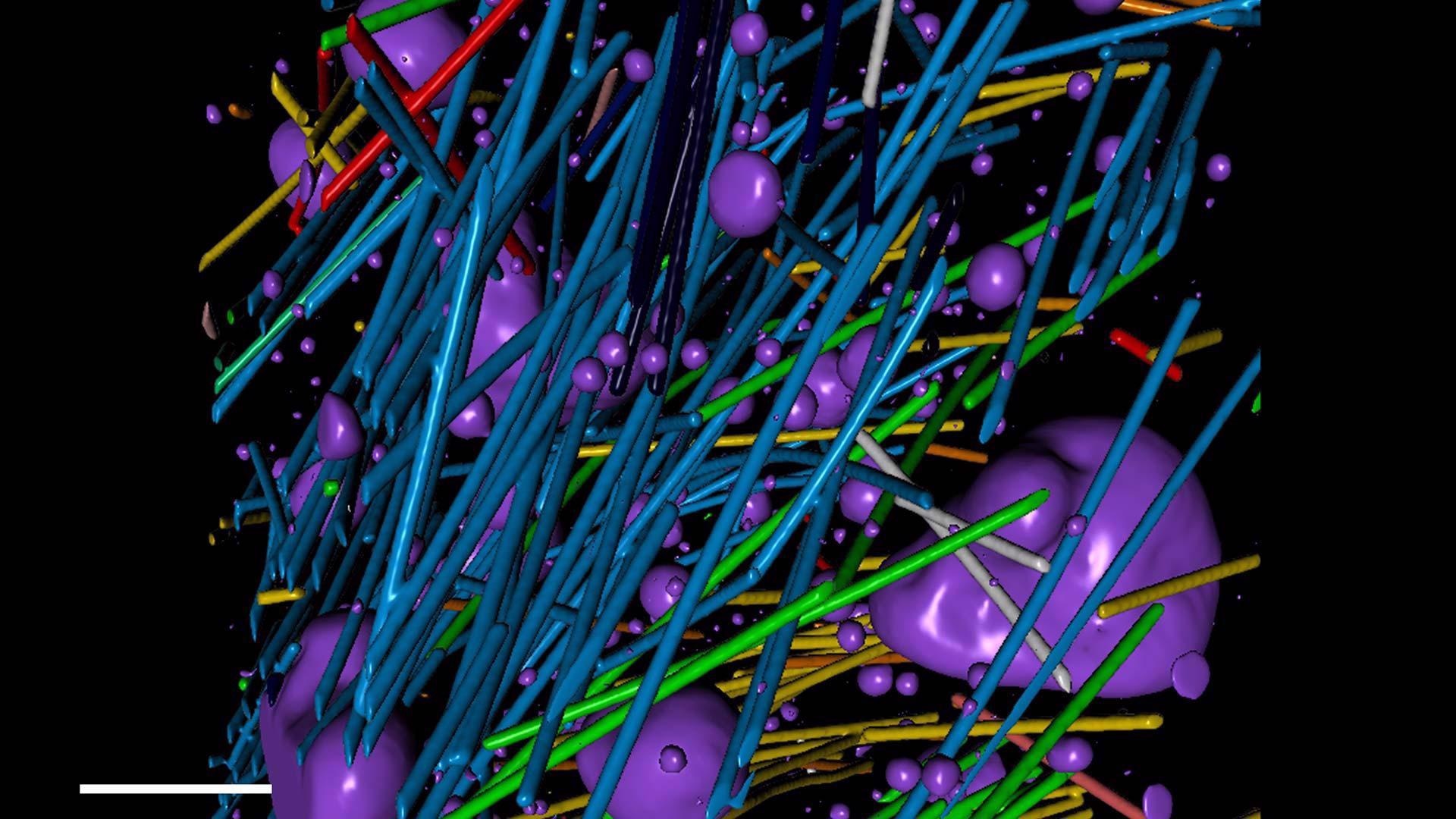

Quantitative volumetric analysis of a steel-reinforced concrete specimen. Voids are rendered in purple. Image Credit: Carl Zeiss Microscopy GmbH

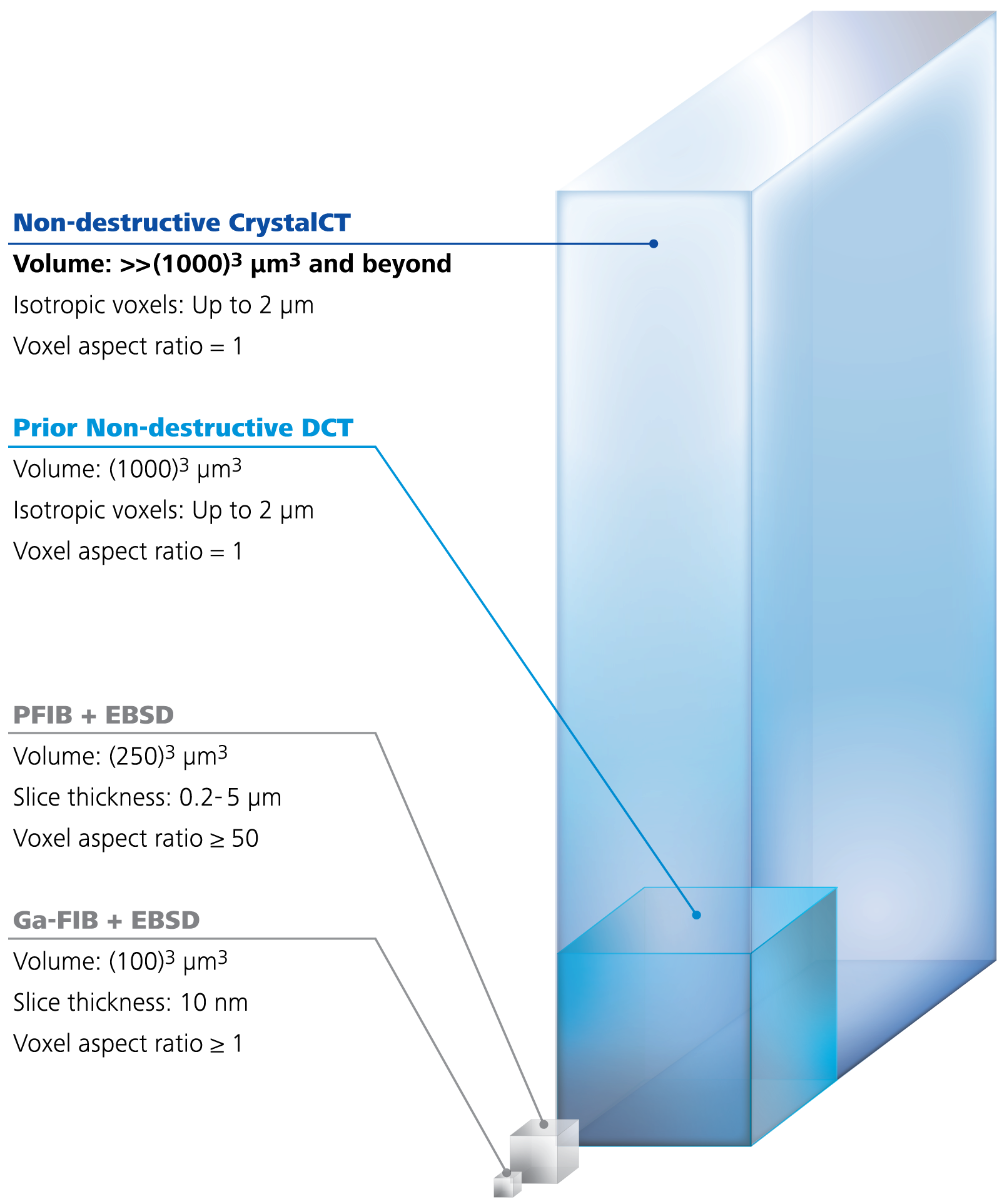

DCT for an Expanded Range of Research Possibilities

Xnovo Technology and ZEISS Research Microscopy Solutions have teamed up to bring breakthrough laboratory diffraction contrast tomography (DCT) capability to market.

DCT on a microCT, which uses 3D grain mapping, allows technical and industrial research centers to image single-phase polycrystalline materials in 3D, encompassing a wide range of metal, mineral, ceramic, semiconductor and pharmaceutical samples.

The custom-made ZEISS Xradia CrystalCT uses precisely engineered aperture and beam stop components to utilize divergent, polychromatic X-Ray beams to spotlight a region of interest and boost sensitivity to polycrystalline samples’ poorer diffraction signals.

Novel DCT acquisition modes eliminate sample size limits, allowing users to investigate a wider range of sample types. Scanning samples faster and with a more precise representation of data is made possible by seamless high-volume grain mapping.

Superior Sample Representivity from Advanced Diffraction Scan Modes

Through groundbreaking diffraction scanning techniques, ZEISS Xradia CrystalCT enhances materials characterization, modeling and innovation.

- Offers exceptional sample representatively

- Allows scanning larger sample volumes

- Simplifies sample prep and handling of irregular/natural sample shapes

- Surges speed

- Reports sample specificity

These sophisticated modes solve some of the problems with traditional DCT data gathering, which assumes that the sample ROI is fully lighted by the aperture field of view (FOV) at all rotating angles.

Improved diffraction scanning modes give helical phyllotaxis schema to handle a broad range of sample shapes and sizes, influenced by nature’s golden angle.

A Powerful MicroCT Platform

On a microCT, ZEISS uses its strong Xradia technology to achieve world-leading efficiency. Users can get high-quality, high-resolution scans with best-in-class contrast using a sturdy stage, adjustable software-controlled source/sample/detector placement, and a huge array detector.

To expose interior elements in their full 3D setting, photograph entire objects or devices. Higher acquisition speeds allow users to run more samples in less time, boosting productivity and profits.

In situ and 4D investigations using non-destructive CT are also possible to determine the actual effect of changing environments over time.

The ZEISS Xradia imaging system blends a tried-and-true hardware design with cutting-edge drift and stability features. CrystalCT routinely exceeds one’s understanding of what a microCT may achieve due to the exceptional stability of this renowned platform.

Applications

Metals, Ceramics, Semiconductors, Geoscience, Pharmaceuticals and more

ZEISS Xradia CrystalCT is a cutting-edge, dramatically new diffraction scanning technology that allows users to trace grain boundary surfaces in their native condition over substantially greater volumes while targeting actual sample shapes that meet the needs of research and industrial labs.

DCT allows for non-destructive 3D grain imaging, unlike previous grain mapping technologies.

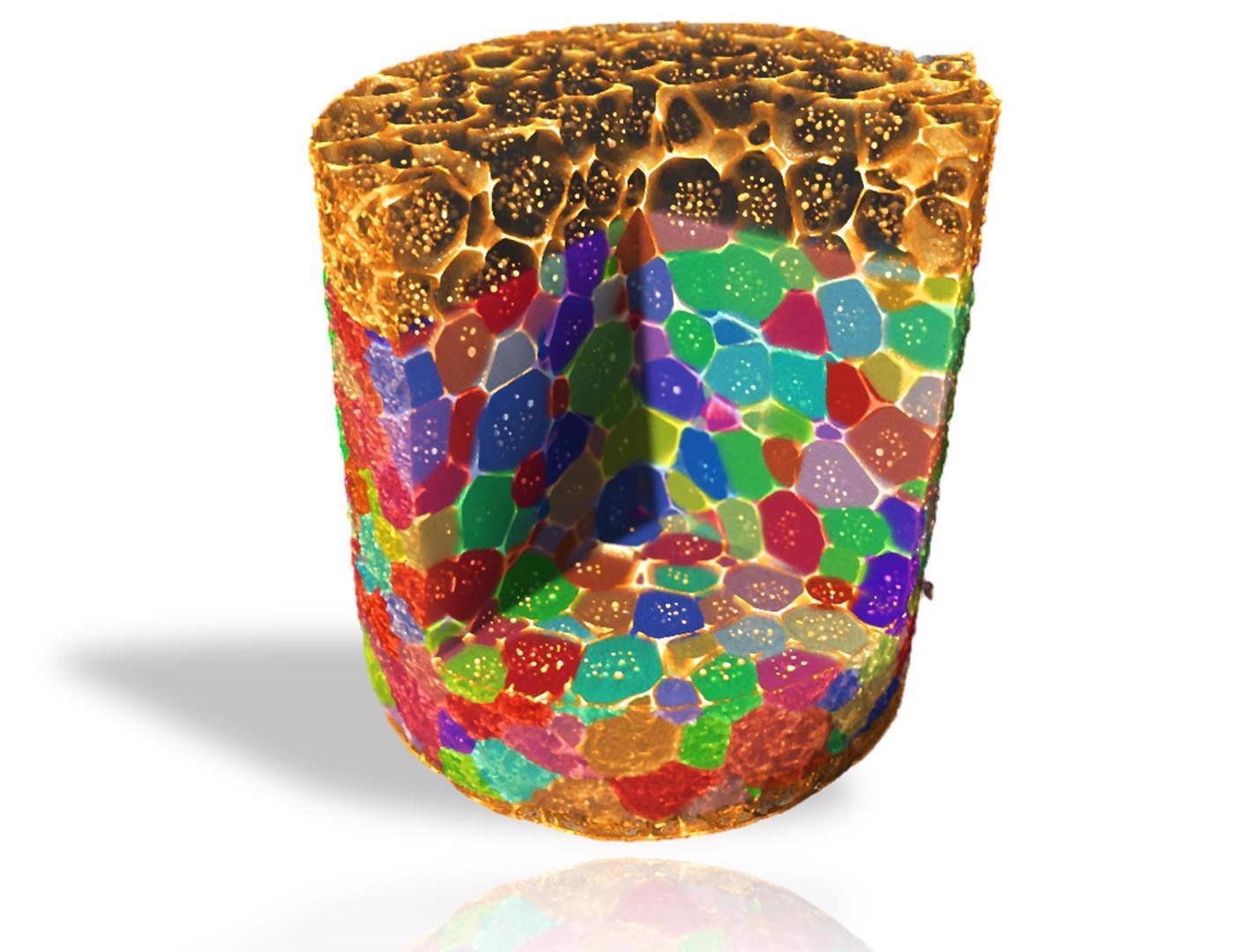

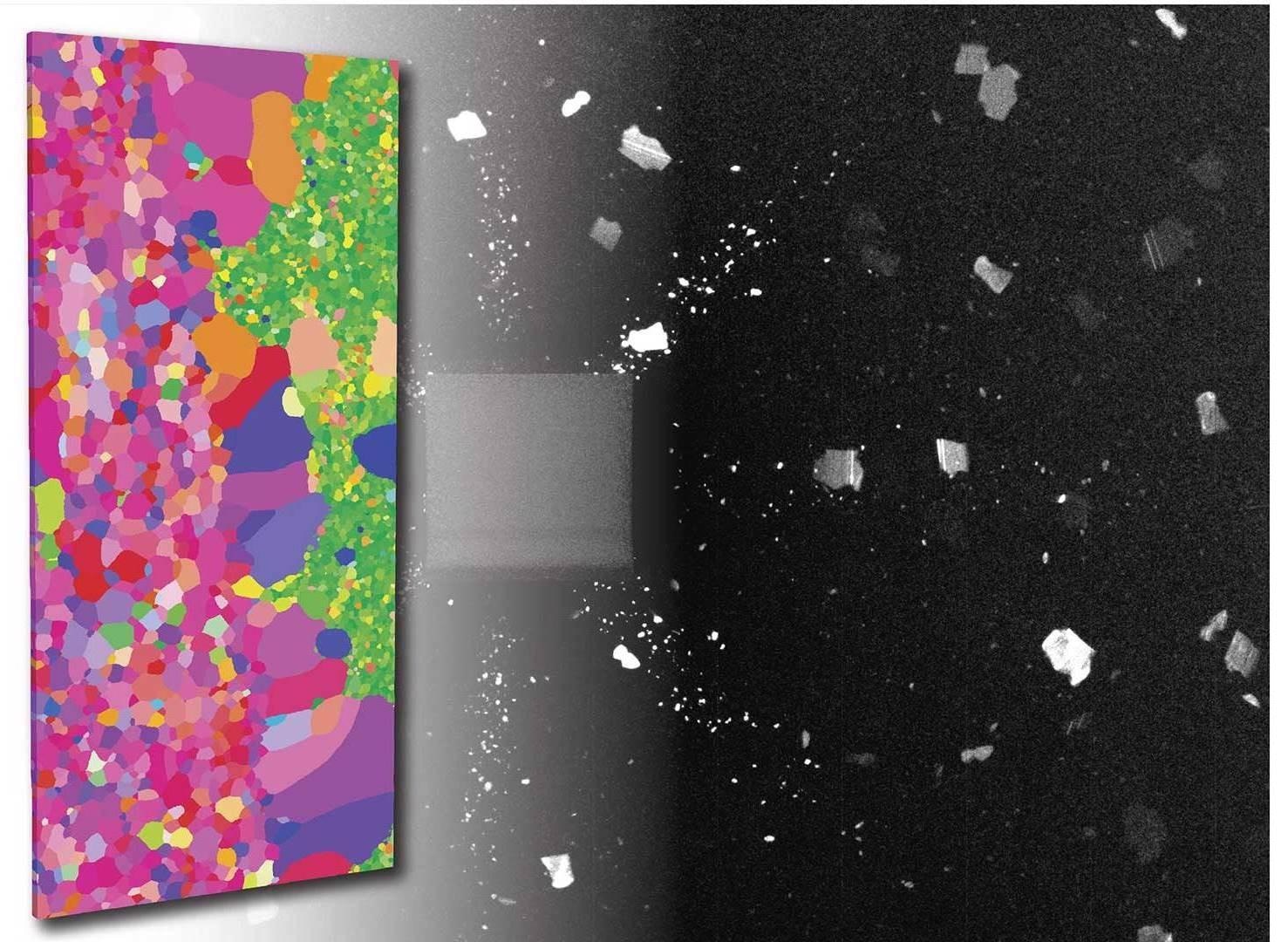

3D grain map of aluminum copper alloy imaged in absorption and diffraction contrast tomography. Image Credit: Carl Zeiss Microscopy GmbH

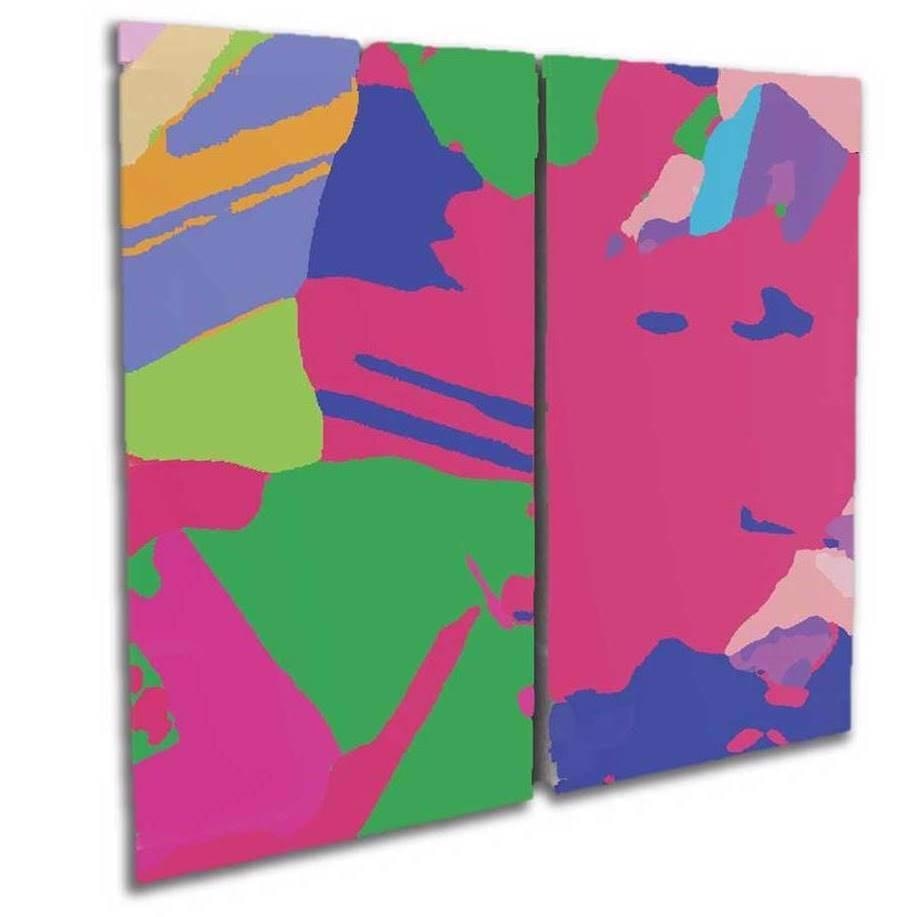

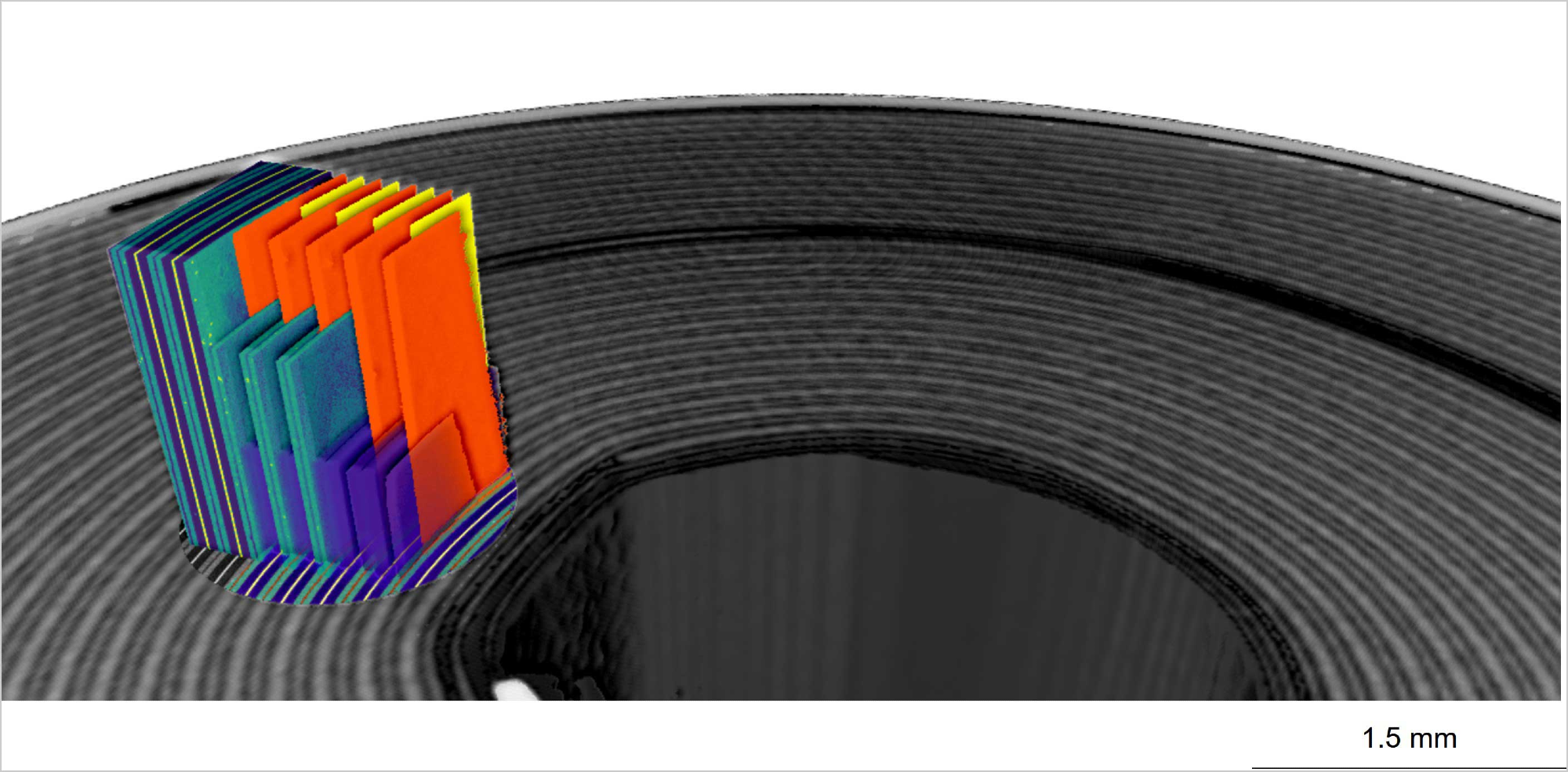

3D grain map of an ultra-thin oriented electrical steel sample with dimensions of (RD) 4 mm, (TD) 2 mm, and (ND) 0.08 mm. Image Credit: Carl Zeiss Microscopy GmbH

3D grain map of polysilicon materials from a solar panel with a height of 30 mm. Image Credit: Carl Zeiss Microscopy GmbH

2D virtual cross-section and a cutaway view of 3D rendering of a mouse embryo embedded in paraffin. Image Credit: Carl Zeiss Microscopy GmbH

Materials Science

- Non-destructive understandings of interior microstructures and overlaid grain maps are not visible by surface imaging procedures like optical or scanning electron microscopy.

- Corresponding data from high-resolution absorption contrast tomography and non-destructive 3D grain mapping distributing size, shape, orientation and grain boundary information.

- 4D imaging through ex situ or in situ experiments to see how materials change, e.g., over mechanical load or corrosion.

- Skill to segment and examine data to acquire quantitative, 3D descriptions of structures and particles.

Metals & Minerals

- Transfer real 3D structures for physics simulations: predict materials properties (mechanical, thermal, etc.) or digital rock simulations using non-destructive 3D tomography data imaging, characterization and modeling of rock cores (up to 4”) with great throughput.

- Comprehend grain size and phase development in 3D for the perception of alloy performance and its need on thermal and mechanical processes.

- Great contrast 3D imaging for in situ flow studies or 3D mineralogy.

Manufacturing

- Accomplish crystallography-based print quality assessment in 3D printed metal parts.

- Accommodate a variety of sample sizes containing large objects in their full 3D context, complementing with 3D grain maps in specific applications.

- Complement or substitute physical cross-sectioning and eradicate the necessity to sacrifice the sample.

- High throughput scanning of intact devices with fast time to results.

Life Sciences

- Rapid, non-destructive confirmation of sample staining and location of features for consequent imaging using 3D electron microscopy.

- Image either stained or unstained hard and soft tissues or biological microstructures with high contrast.

Technology Insights

For crystallographic imaging, sample representatively — obtaining enormous quantities of real data to generate high-fidelity computational models—has been a concern.

Improved DCT modes of the ZEISS Xradia CrystalCT eliminate some of the previous limitations of traditional DCT data gathering, which requires that the ROI in the sample is completely lit by the aperture field of view (FOV) for all rotational angles of the sample.

ZEISS Xradia CrystalCT advanced diffraction scanning modes contain:

- Helical Phyllotaxis: For cylindrical samples with a high aspect ratio, helical phyllotaxis rotation is used.

- Helical Phyllotaxis Raster: For samples that are frequently wider than the field of vision, a helical phyllotaxis raster is used.

- Helical Phyllotaxis HART: The challenge of flat or plate-like sample imaging is solved by phyllotaxis with high aspect ratio tomography or HART.

Image Credit: Carl Zeiss Microscopy GmbH

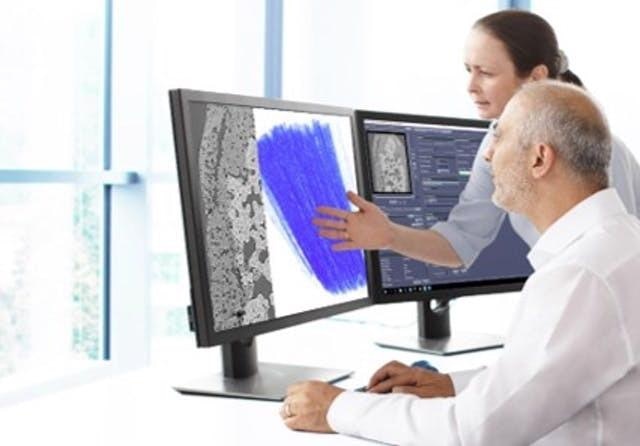

3D Grain Reconstruction

Index Grain Data Precise, Fast and Automated

Image Credit: Carl Zeiss Microscopy GmbH

Users begin reconstructing after the first acquisition, which is the first phase in the workflow. Load the diffraction and absorption tomography data into GrainMapper3D. Allow it to use back and forward projections to find viable choices for grain orientations in a given polycrystal.

The next stage is to conduct an automated, iterative search for grains in the sample volume. The whole description of the indexed grains is contained in grain reconstruction findings as stacks of slices of volume datasets.

Finally, use the standalone GrainMapper3D Viewer tool to communicate 3D LabDCT data with the customers and partners.

3D Grain Mapping

Get All Information in One File

Image Credit: Carl Zeiss Microscopy GmbH

The last step is to compile all of the data into a single file. All grains in the sample volume have their shape, orientation and geographic coordinates transferred into an open data format.

Conclude the experiment by analyzing the results with bespoke software or simulation tools. The more sophisticated, lower symmetry crystal systems are now supported by sophisticated indexation methods.

Accessories

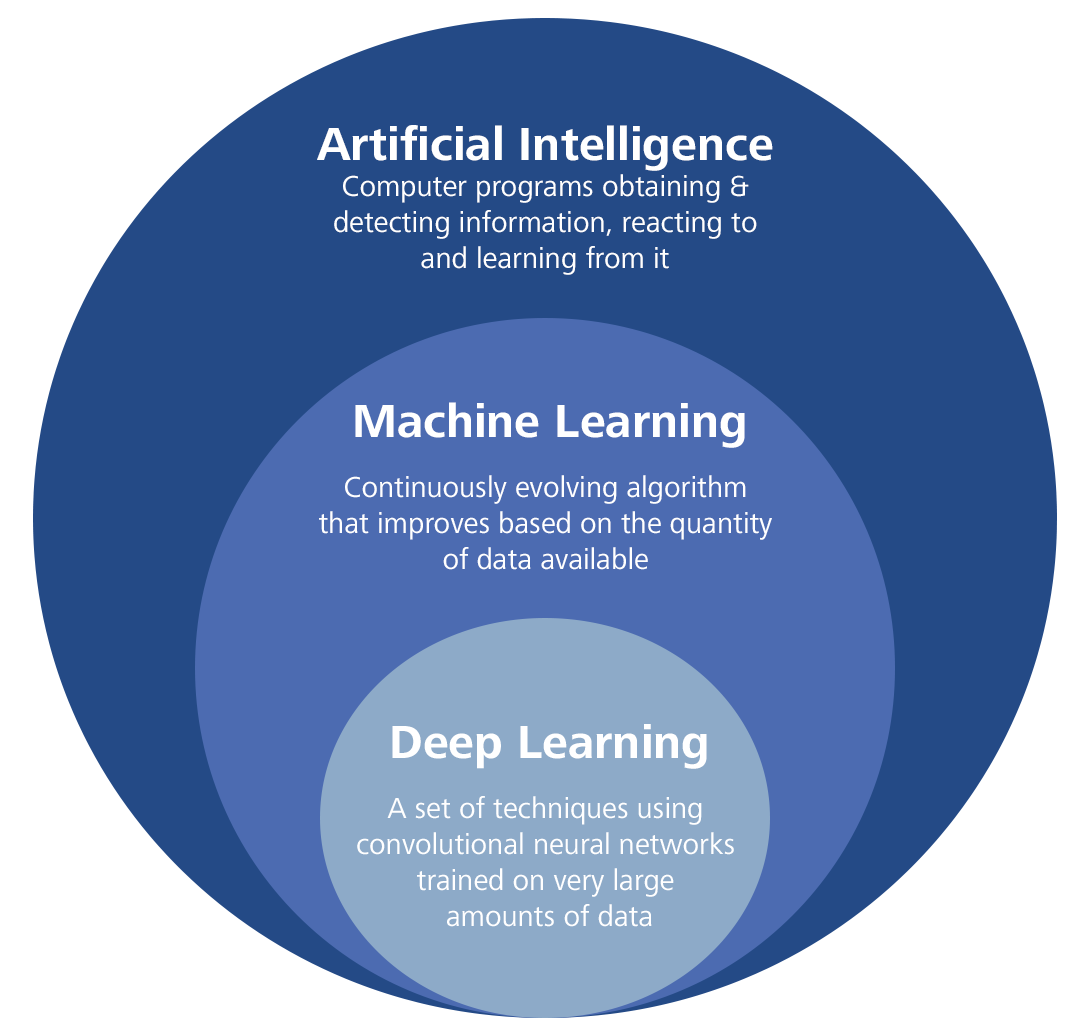

ZEISS Advanced Reconstruction Toolbox

Better Image Quality, Higher Throughput

Artificial Intelligence (AI)-driven reconstruction technologies. Image Credit: Carl Zeiss Microscopy GmbH

On the ZEISS Xradia 3D X-Ray microscope (XRM) or microCT, Advanced Reconstruction Toolbox (ART) delivers Artificial Intelligence (AI)-driven reconstruction methods.

Users may address some of the most difficult imaging difficulties in new and imaginative ways if users have a strong understanding of both X-Ray physics and applications.

Explore how OptiRecon, two variations of DeepRecon, and PhaseEvolve, the distinctive modules of ART, improve data acquisition and reconstruction speed and image quality without losing resolution.

With the Advanced Reconstruction Toolbox, users can:

- Disclose subtle differences through enhanced contrast-to-noise

- Advance data collection and analysis for precise and quicker decision-making

- Significantly improve image quality

- Attain superior interior tomography or throughput on a wide-ranging class of samples

- Surge speed at an order of magnitude for sample classes necessitating repetitive workflow

Image Credit: Carl Zeiss Microscopy GmbH

Workstation-based solutions for quick access and usage are available as optional modules:

- OptiRecon for iterative reconstruction

- PhaseEvolve for contrast enhancement

- DeepRecon Pro & Custom for Deep learning-based reconstruction

ZEISS DeepRecon Pro provides a straightforward, uncomplicated, and powerful application of AI and deep neural network technology for enhancing X-Ray tomography results without prior knowledge of deep learning technology. It helps us to reduce the scan time required for in situ fluid-rock interaction experiments when we need to work with long exposure times.

Dr. Markus Ohl, X-Ray microscopy, EPOS-NL MINT, Utrecht University, NL

In Situ Experiments

Push the limits for scientific advancement

Tensile testing of laser-welded steel under increasing load. Image Credit: Carl Zeiss Microscopy GmbH

ZEISS Xradia X-Ray systems offer the industry’s most comprehensive 3D imaging solution for in situ rigs, including high-pressure flow cells, tension, compression and heat stages.

Using the non-destructive nature of X-Ray inquiry to expand the studies into the dimension of time with 4D experiments, users may go beyond the three dimensions of space.

In situ rigs ranging from high-pressure flow cells to tension, compression and temperature stages, as well as user-customized designs, can be accommodated on ZEISS Xradia microCT platforms.

To the ZEISS Xradia CrystalCT, users may add the additional in situ Interface Kit, which contains a mechanical integration kit, a durable wiring guide and other facilities (feed-throughs) as well as recipe-based software that facilitates control from inside the Scout-and-Scan user interface.

Transform the ZEISS Xradia CrystalCT to an Xradia 620 Versa X-Ray microscope for the highest performance tomographic imaging of samples within in situ chambers or rigs when the demands need to push the resolution limits of the in situ research.

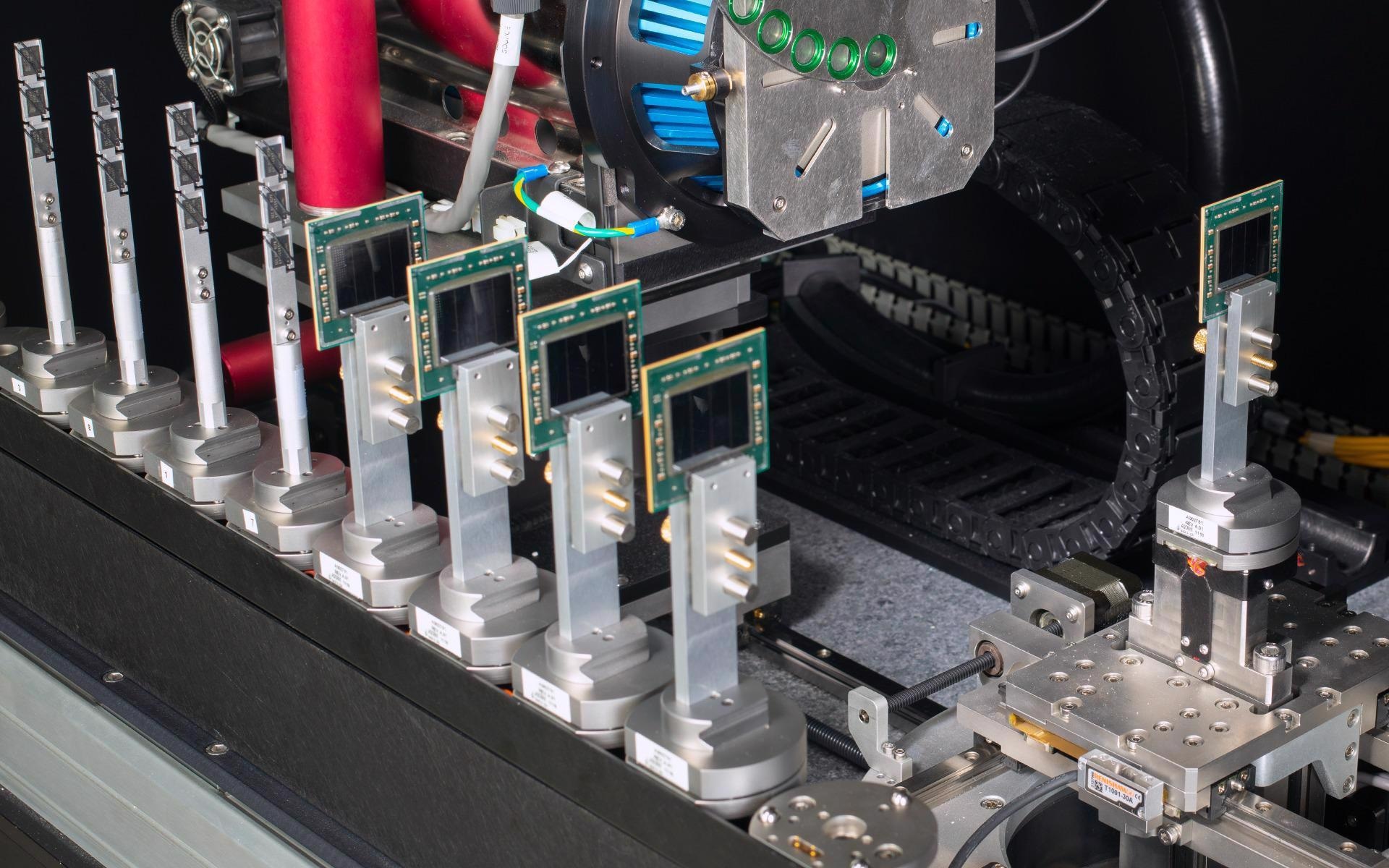

Autoloader

Increase Sample Handling Efficiency

Autoloader option enables users to program up to 70 samples at a time to run sequentially. Image Credit: Carl Zeiss Microscopy GmbH

The optional Autoloader is offered for all instruments in the ZEISS X-Ray microscope platforms, allowing users to get the most out of the instrument. By queueing numerous jobs, users may decrease the frequency of user involvement while increasing efficiency.

Set up 14 sample stations, each of which can hold up to 70 samples, to run overnight or over several days. Mechanical stability that is unrivaled allows for high-volume quantitative repetitive scanning of similar samples.

Software

Create Efficient Workflows by Using the Simple Control System

The Scout-and-Scan Control System makes it simple to scout a target area and set scanning parameters. Make use of the simple system in the central lab, where users may have varying degrees of experience.

Benefit from:

- Multiple energies

- Multiple samples with Autoloader option

- Micropositioning capability with a simple mouse click

- Internal camera for sample viewing

- Recipe control (set, save, recall)

Scout-and-Scan Control System. Image Credit: Carl Zeiss Microscopy GmbH

ZEISS Mineralogic - Automated Mineralogy

Image Credit: Carl Zeiss Microscopy GmbH

ZEISS SEM, XRM and microCT instruments were used to perform phase identification and textural analysis in 2D and 3D.

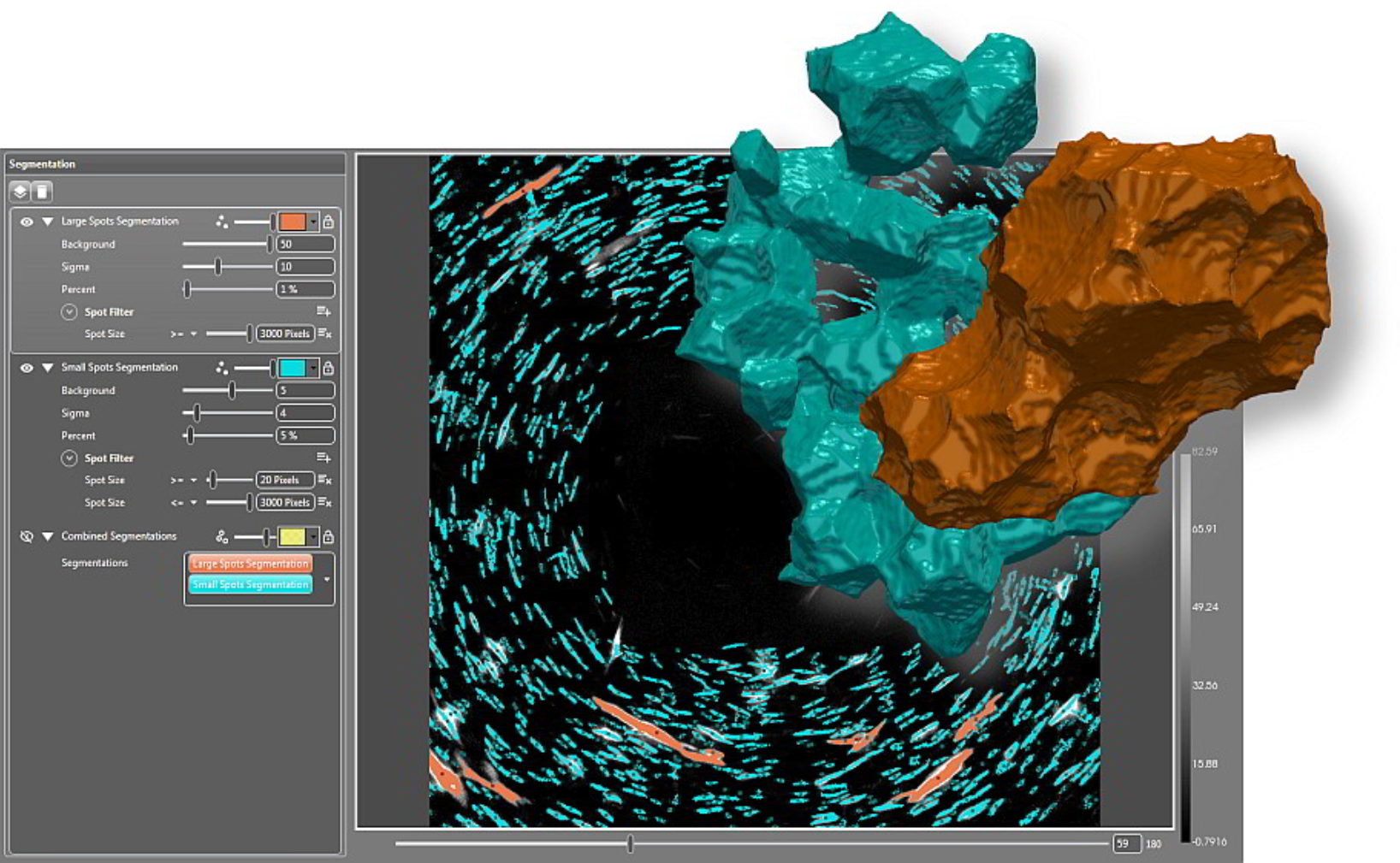

Visualization and Analysis Software

ZEISS Recommends Dragonfly Pro from Object Research Systems (ORS)

Image Credit: Carl Zeiss Microscopy GmbH

Advanced analysis and visualization software for 3D data gathered using a range of technologies such as X-Ray, FIB-SEM, SEM and helium ion microscopy.

ORS Dragonfly Pro is a simple, full and configurable toolkit for the visualization and analysis of huge 3D grayscale data, exclusively available through ZEISS. Dragonfly Pro allows users to navigate, annotate and create media files from the 3D data, which includes video production. To evaluate the results, use image processing, segmentation and object analysis.

ZEISS ZEN Intellesis for Image Segmentation in Microscopy

Image Credit: Carl Zeiss Microscopy GmbH

Use deep learning to quickly separate the photographs and gain access to their true value—the data they contain. All subsequent image analysis procedures are built on the foundation of picture segmentation. Deep learning and Python are used by ZEISS ZEN Intellesis to simply provide repeatable segmentation results, even for non-experts.

After training the software, ZEISS ZEN Intellesis can automatically segment a collection of hundreds of photos. Users save time while reducing user bias.