Several users have asked Carl Zeiss to describe what ZEN core is about. ZEN core tackles more than just microscopy imaging. It is the most extensive suite of analysis, imaging, and connectivity tools for multi-modal microscopy in associated material laboratories.

Users can learn how ZEN core helps enhance laboratory efficiency via contextual data analysis, automated image segmentation, and centralized data management.

Image Credit: Carl Zeiss Microscopy GmbH

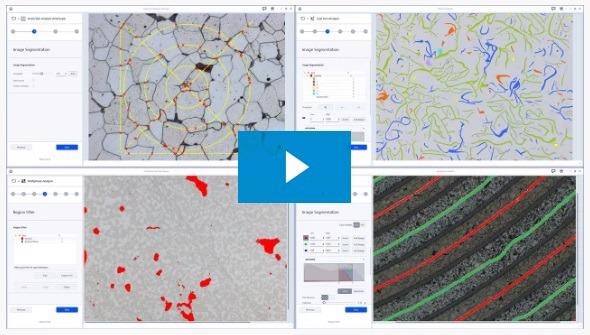

Material Modules

Metallography and Material Inspection

How to improve routine metallography tasks? How to deal with new materials? How can you avoid user bias and keep your laboratory efficient? Instead of just buying features, with ZEN core you get the full productivity package to take your materials investigation to the next level. Image Credit: Carl Zeiss Microscopy GmbH

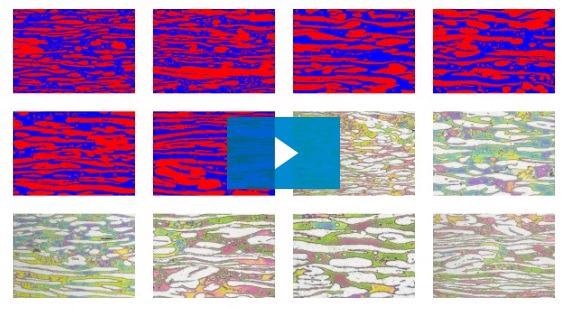

ZEN Intellesis

Automated Image Segmentation

ZEN Intellesis applies the power of machine learning to the task of segmenting multi-dimensional images, including 3D datasets. Images that had to be processed manually can now be analyzed automatically, by training ZEN Intellesis to segment them for you. Image Credit: Carl Zeiss Microscopy GmbH

Non-Metallic Inclusion Analysis (NMI)

Ensuring Steel Quality

Steel is one of the most common engineering materials. Despite their small size, non-metallic inclusions in steel can affect its mechanical, processing, and corrosion properties. ZEN Non-Metallic Inclusions is your solution for rapid, reliable NMI analyses according to industry standards. Image Credit: Carl Zeiss Microscopy GmbH

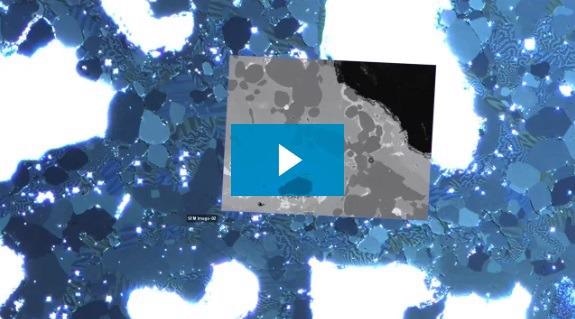

ZEN Connect

Images and Data in Context

With ZEN Connect, you can visualize different microscopy images and data from the same sample—in context and in one place. Discover the correlations between micrographs at different scales. Benefit from integrated reporting across the connected datasets. Image Credit: Carl Zeiss Microscopy GmbH

GxP Module

Secure Microscopy Processes

Recent scandals in automotive or the oil and steel industries have highlighted the consequences of wrong or even falsified data. The GxP module makes all your analyses traceable and therefore compliant with regulation and certification requirements. Image Credit: Carl Zeiss Microscopy GmbH

ZEN Data Storage

Central Data Management

ZEN Data Storage enables centralized management of microscope presets, workflows, data, and reports—from different systems and locations. Separate microscopy imaging from post-acquisition processing to allow everyone in the lab to work more efficiently. Image Credit: Carl Zeiss Microscopy GmbH

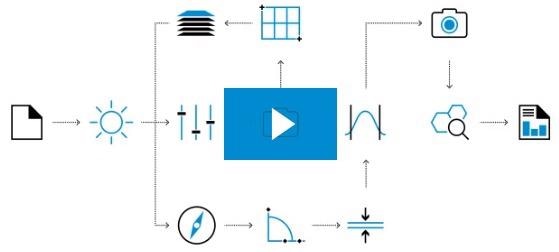

ZEISS ZAPHIRE Offline Evaluation

Bridging Microscopy and Metrology

Workpieces are getting smaller; manufacturing tools are able to produce impressively small features with very ambitious tolerances. NEO pixel brings metrology functionalities to microscopy – giving you higher quality and better productivity. Image Credit: Carl Zeiss Microscopy GmbH