Xradia Context from ZEISS is known as a large field-of-view, non-destructive 3D X-Ray micro-computed tomography system. With the help of a strong stage and adaptable software-controlled source or detector positioning, users can image big, heavy (25 kg), and tall samples in their complete 3D context, and small samples with high resolution and elaborate.

- Execute non-destructive failure analysis to determine internal defects without cutting the sample or user's workpiece.

- Users can achieve 3D data on fully intact electronic components, huge raw materials samples or biological specimens.

- Conduct 4D evolutionary studies, via in situ or ex-situ treatment or sample manipulation.

- Describe and measure performance-defining heterogeneities in users’ materials, like inclusions, cracks, porosity, defects or multiple phases.

- Users can link to the ZEISS correlative microscopy environment and execute non-destructive 3D imaging to determine regions of interest for consequent high-resolution 2D or 3D electron microscopy imaging.

Highlights

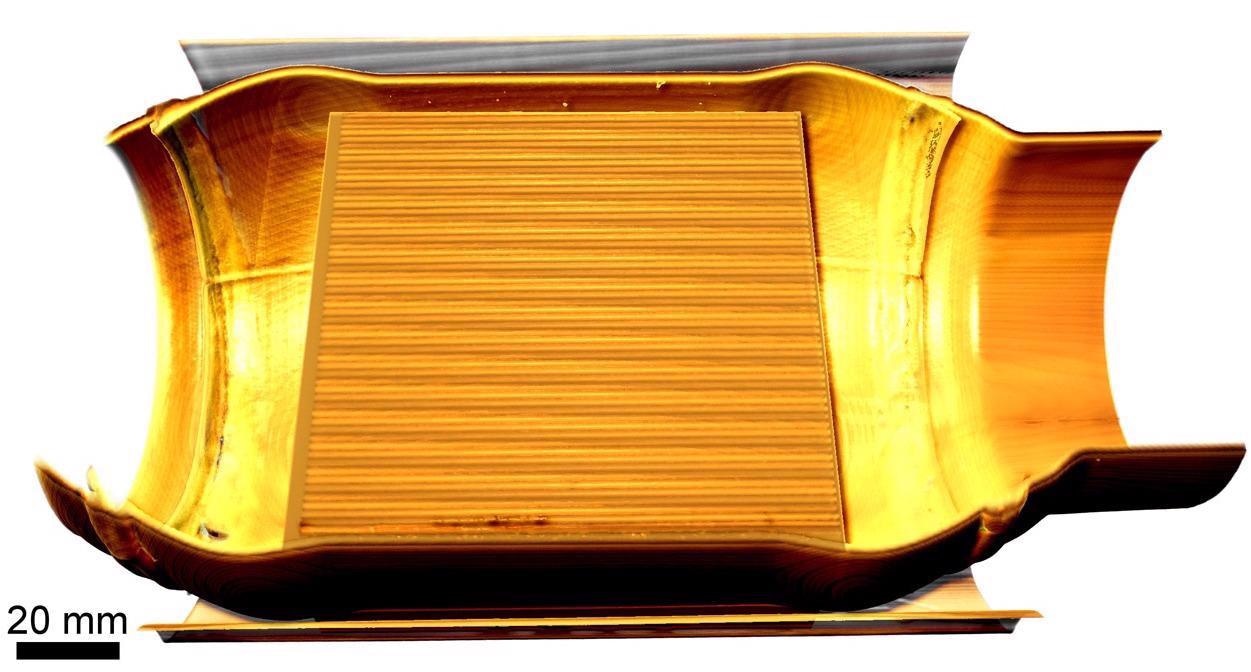

Virtual cutaway view of the interior of an intact catalytic converter. Image Credit: Carl Zeiss Microscopy GmbH

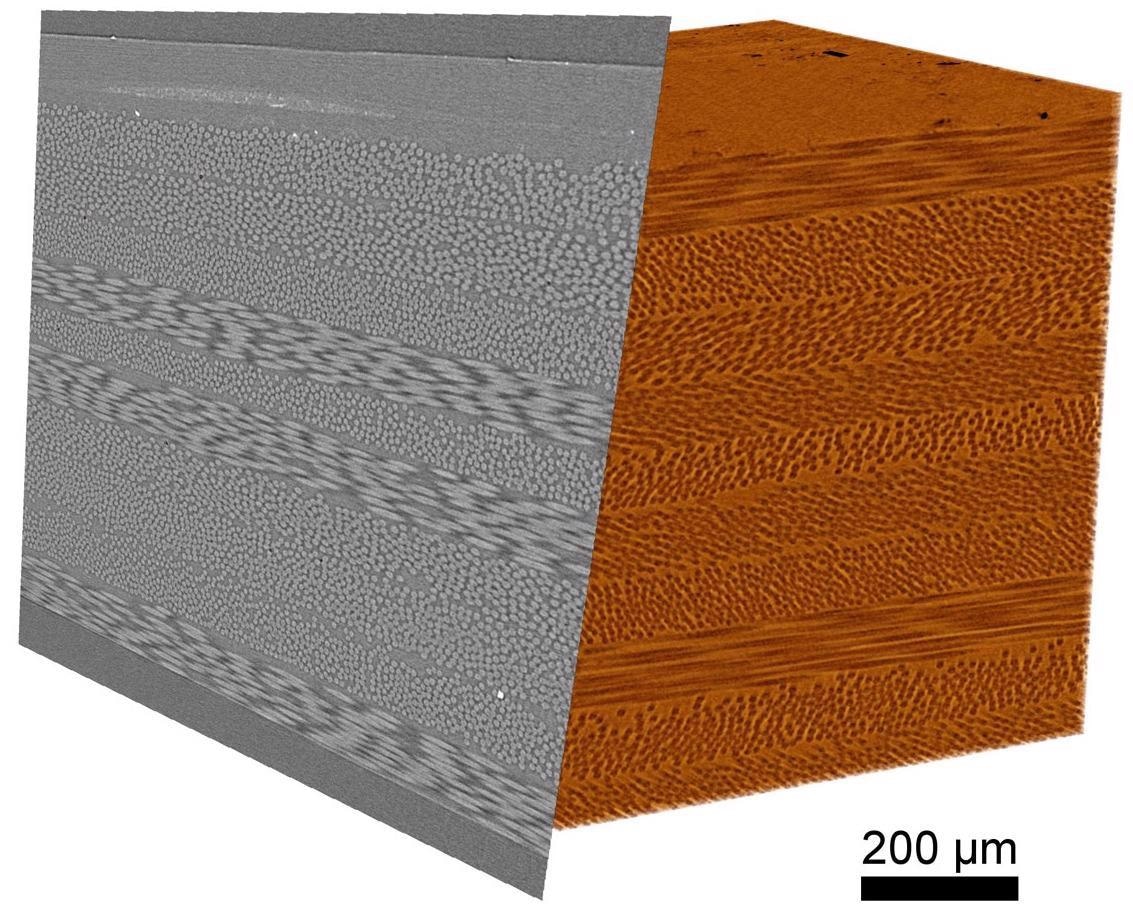

3D rendering and clipping plane of a composite sample with carbon and glass fibers. Image Credit: Carl Zeiss Microscopy GmbH

Full field of view imaging of a bear jaw. Image Credit: Carl Zeiss Microscopy GmbH

Full context 3D Imaging

- Users can resolve fine details in their complete 3D context, even within a comparatively huge imaging volume with a high pixel density detector of six megapixels.

- Improve geometric magnification with small samples to determine and characterize micron-scale structures with high contrast and clarity.

- With image quality, users can achieve up to 10X quicker.

- Users can mount and align their specimens rapidly or expand their system with an optional Autoloader for automated handling and sequential scanning ranging up to 14 samples.

- Users can benefit from a simplified acquisition workflow, data reconstruction and fast exposure times.

Based on the Proven Xradia Platform

- Execute 4D studies to quantify variations in the microstructure of materials under differing conditions.

- With the help of Xradia context microCT, users can profit from years of development as it is made upon the same base platform as the Xradia Versa series.

- The easy-to-use Scout-and-Scan control system offers users an effective workflow surrounding.

- Users can benefit from a system that has been aimed at guaranteeing stability, progresses in high resolution, high-quality data acquisition and reconstruction.

Convertible to X-Ray Microscopy (XRM)

- As there is a development in the user’s imaging requirements, so must their instrument: Xradia Context currently meets the ZEISS X-Ray imaging portfolio, thereby profiting from ZEISS’s continuing commitment to expand the abilities and functionality of its systems in the field.

- This sets the stage for 3D tomographic imaging that is all set to grow with their requirements — Users Xradia Context microCT is the only microCT that could be converted at any point to a ZEISS Xradia 5XX Versa 3D X-Ray microscope (XRM).

- Add FPX (flat panel extension) for performance and flexibility in spatial resolution and improved contrast and acquisition techniques.

- It is possible to add the in situ Interface Kit and load stages to analyze material evolution in 4D.

Accessories

Users can upgrade their microscope with extra accessories to improve the user's microscope’s capability.

ZEISS Advanced Reconstruction Toolbox

Better image quality, higher throughput.

Image Credit: Carl Zeiss Microscopy GmbH

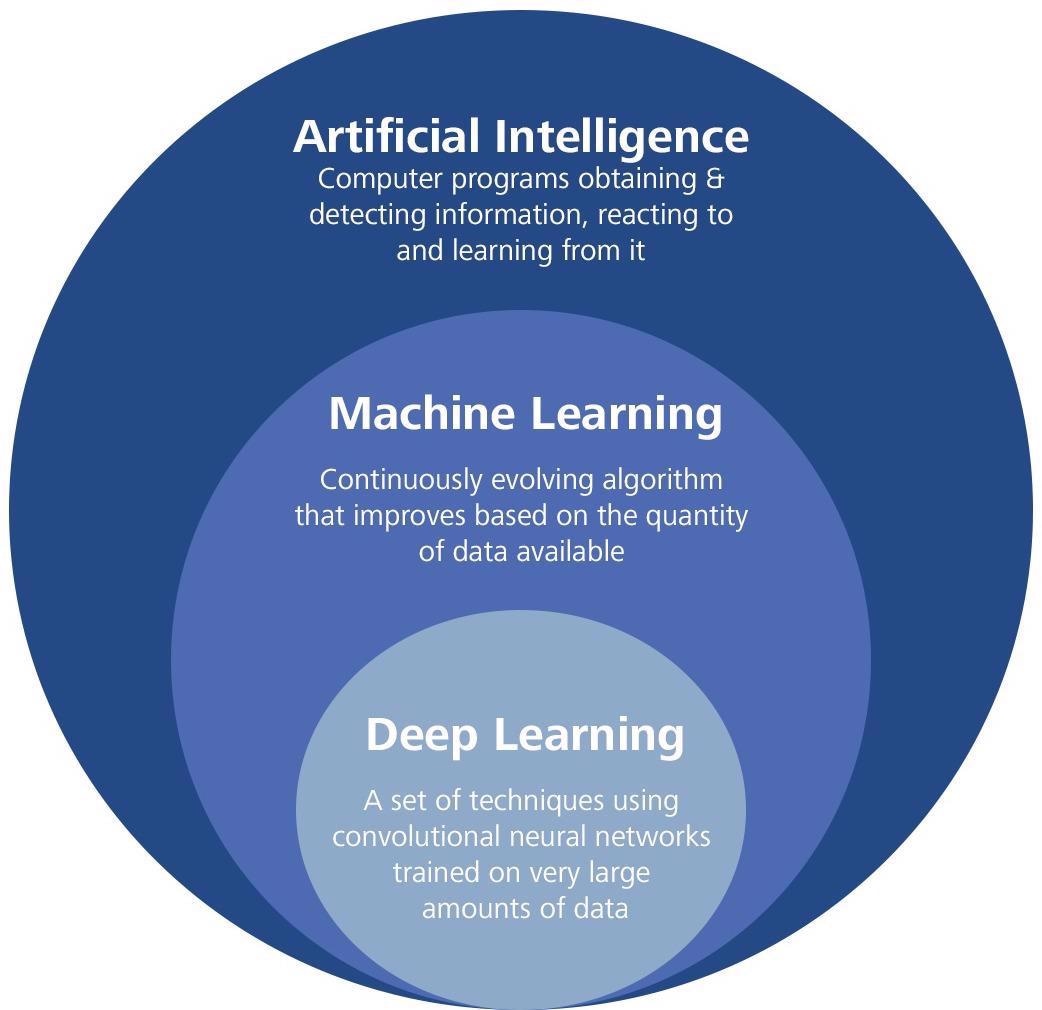

Advanced Reconstruction Toolbox (ART) initiates Artificial Intelligence (AI)-driven reconstruction technologies on their ZEISS Xradia 3D X-Ray microscope (XRM) or microCT. A deep understanding of both X-Ray physics and applications allows users to resolve a few of the tough imaging difficulties associated with new and innovative approaches.

Find out how the speed of reconstruction and data acquisition as well as image quality are improved without compromising resolution with the help of OptiRecon, two variants of PhaseEvolve and DeepRecon, the special modules of ART.

With the help of the Advanced Reconstruction Toolbox, it is possible for users to:

- Enhance data collection and analysis for precise and quicker decision-making

- Significantly improve image quality

- Disclose delicate differences via enhanced contrast-to-noise

- Obtain excellent interior throughput or tomography on a wide class of samples

- Speed can be increased at an order of magnitude for sample classes that are in need of repetitive workflow

Listed below are the optional modules which are workstation-based solutions for simple access and usability:

- DeepRecon Pro and Custom for Deep learning-based reconstruction

- Comes with OptiRecon for iterative reconstruction

- PhaseEvolve available for contrast improvement

Image Credit: Carl Zeiss Microscopy GmbH

ZEISS DeepRecon Pro provides a straightforward, uncomplicated, and powerful application of AI and deep neural network technology for enhancing X-Ray tomography results without prior knowledge on deep learning technology. It helps us to reduce the scan time required for in situ fluid-rock interaction experiments when we need to work with long exposure times.

Dr. Markus Ohl, X-Ray microscopy, EPOS-NL MINT, Utrecht University, NL

Fields of Application

Materials Science, Engineering, Geoscience and More

Xradia Context serves a range of requirements in central or R&D laboratories — materials science, geoscience, life science, engineering and more — and extends capabilities when users' imaging requires development.

Xradia Context offers 3D imaging for applications in the fields of materials, raw materials characterization, life and geoscience research, and even manufacturing and assembly failure analysis and quality control.

3D rendering of a light bulb. Context can be used to perform full sample scanning to check internal structures or identify defects in manufactured components. Image Credit: Carl Zeiss Microscopy GmbH

Cutaway view of 3D rendering of a mouse embryo embedded in paraffin. Internal structures are visible with high contrast. Image Credit: Massachusetts General Hospital

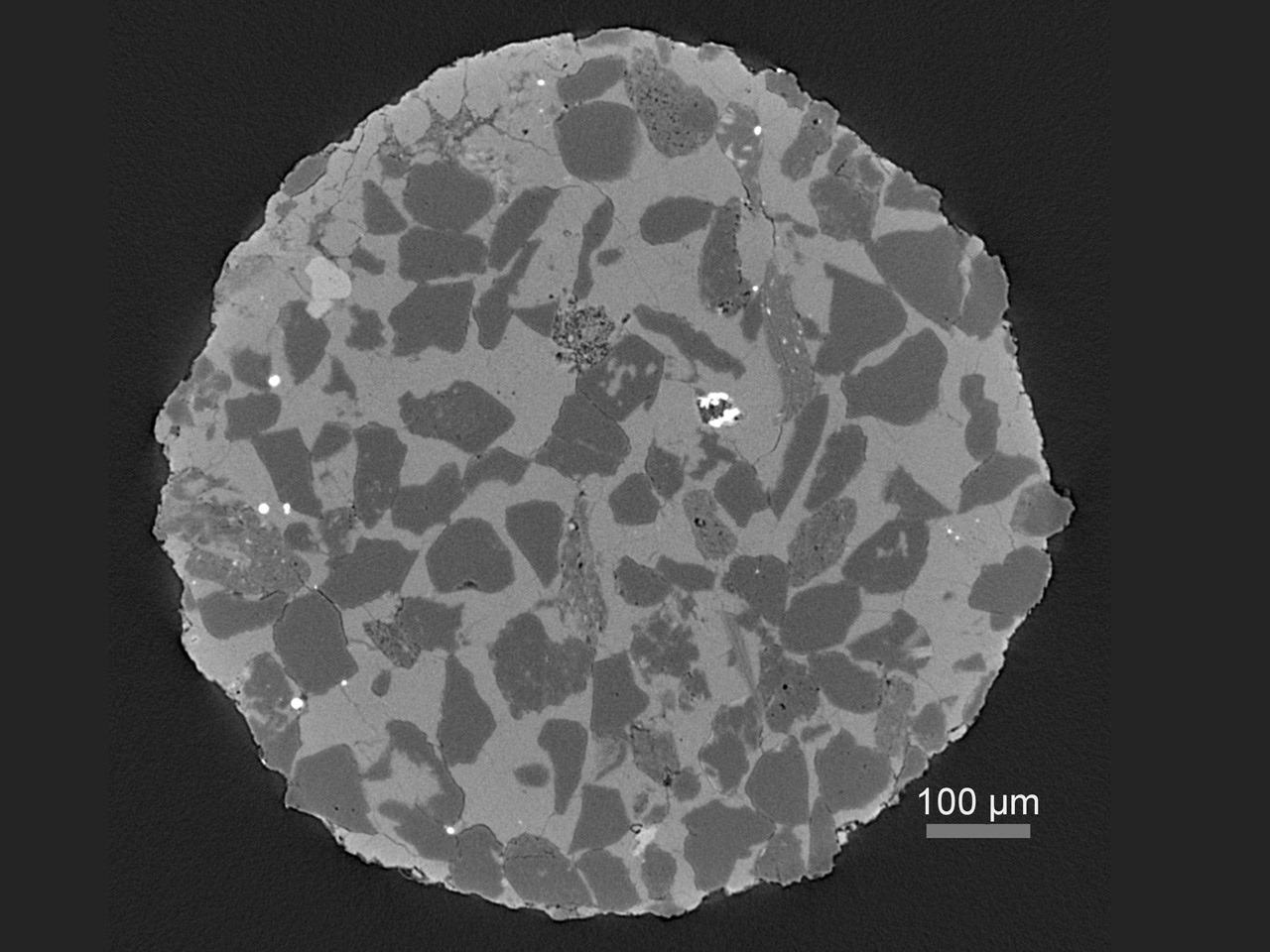

Virtual cross-section through a heterogeneous rock sample revealing multiple phases and porosity. Image Credit: Carl Zeiss Microscopy GmbH

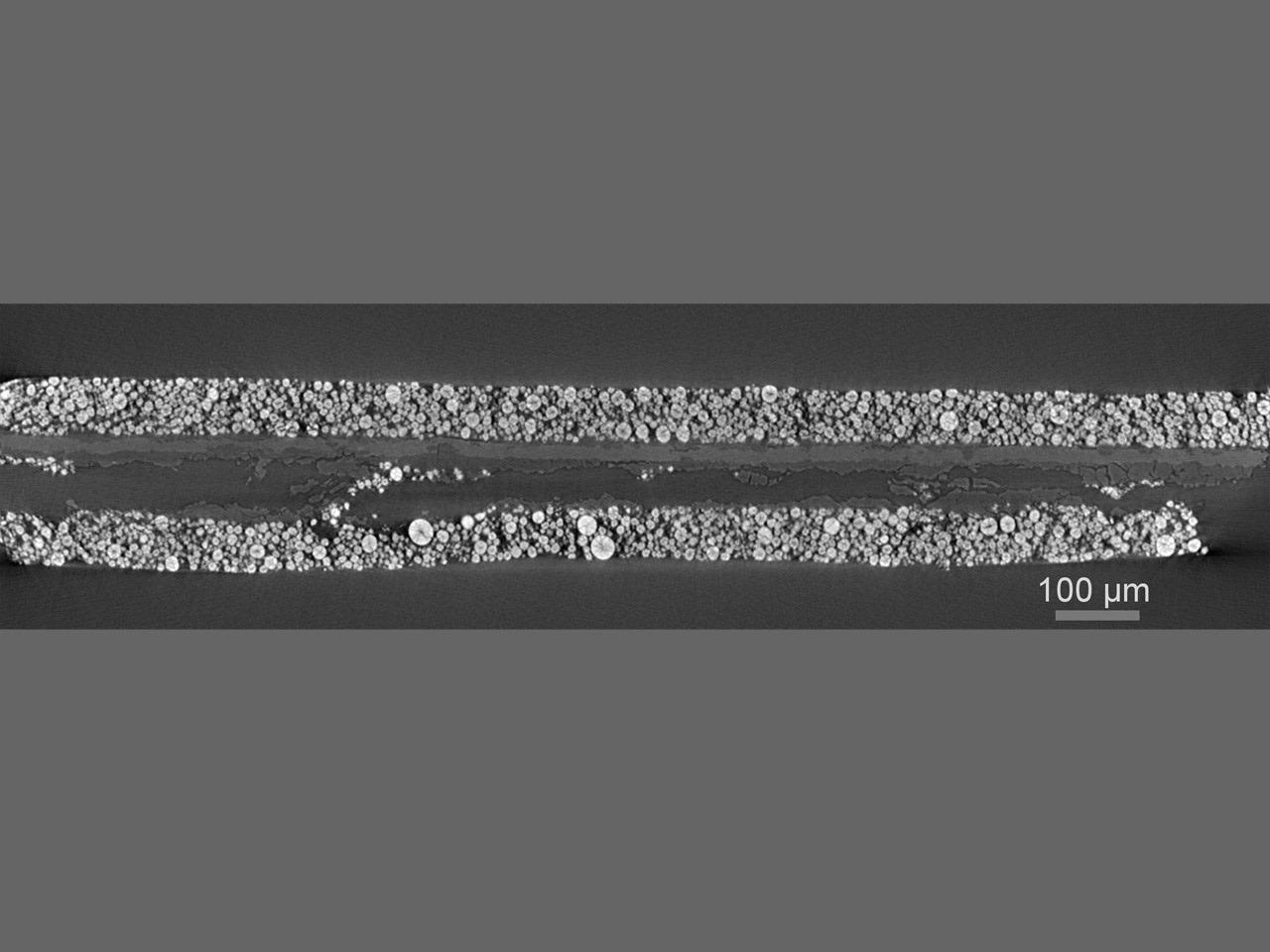

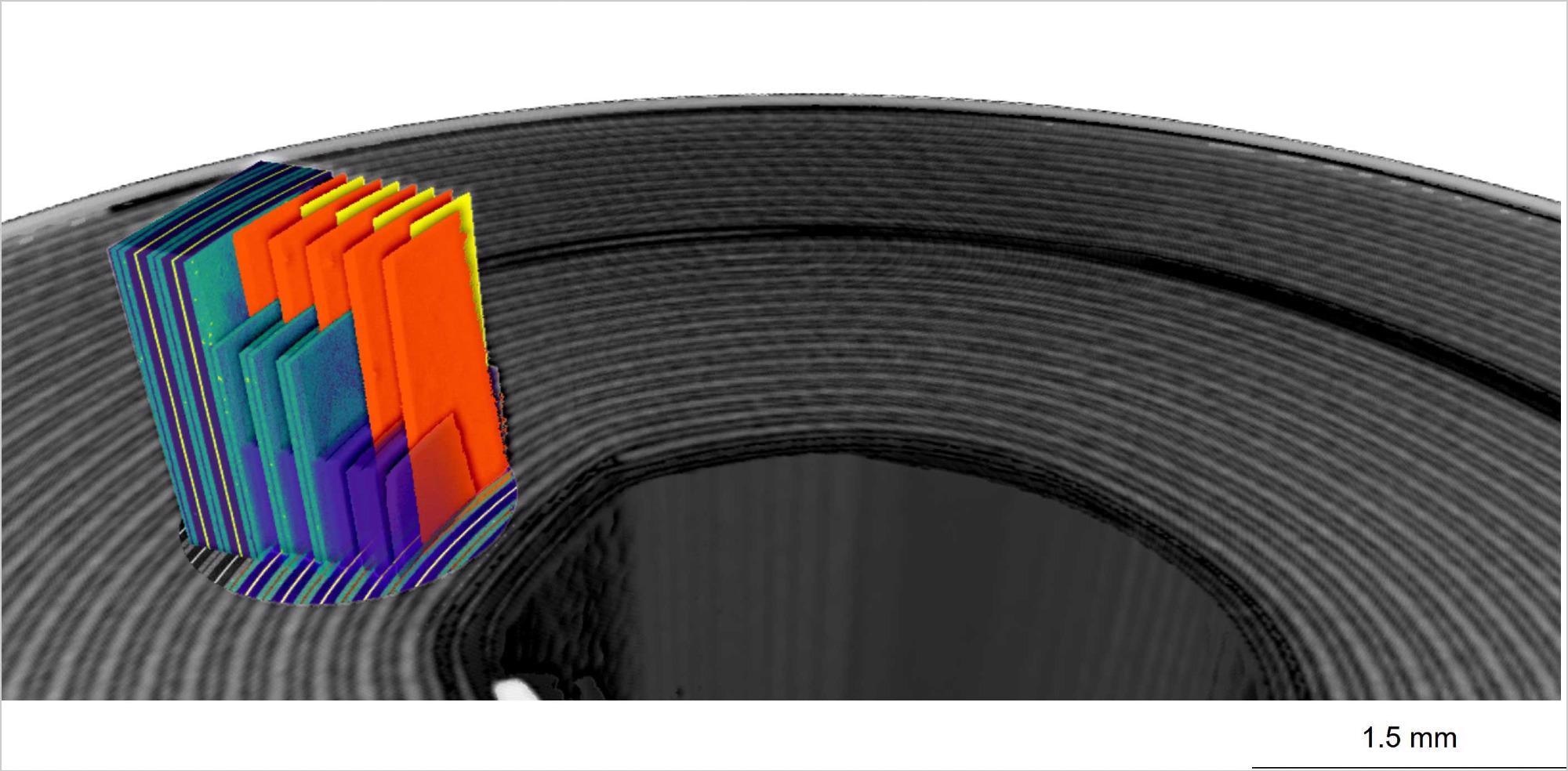

Virtual cross-section through a cycled and de-packaged lithium-ion battery, revealing damage in the current collector and cathode layers. Image Credit: Prof. D. U. Sauer and Prof. E. Figgemeier, ISEA, RWTH Aachen University

3D rendering results from a rapid scan of a turbine blade to evaluate geometry and inspect for internal defects or cracks. Image Credit: Carl Zeiss Microscopy GmbH

Software

Create Efficient Workflows by Using the Simple Control System

It is possible for users to easily scout a region of interest and define scanning parameters within the Scout-and-Scan Control System. Take advantage of the user-friendly system in their central laboratory where users might have a range of experience levels.

Benefit from:

- Internal camera available for sample viewing

- Recipe control (set, save, recall)

- Micropositioning capability with just a simple mouse click

- Multiple samples come with the Autoloader option

- Multiple energies are available

Scout-and-Scan Control System. Image Credit: Carl Zeiss Microscopy GmbH

ZEISS Mineralogic-Automated Mineralogy

Phase identification and textural analysis in 2D and 3D using ZEISS SEM, XRM and microCT systems.

Image Credit: Carl Zeiss Microscopy GmbH

Visualization and Analysis Software

ZEISS Recommends Dragonfly Pro from Object Research Systems (ORS)

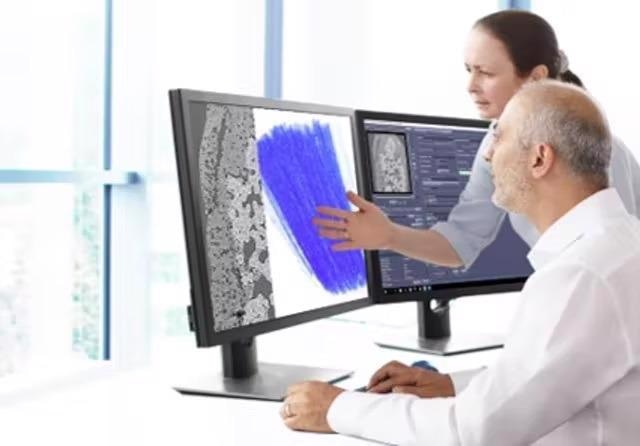

An advanced analysis and visualization software solution that has been developed for user’s 3D data obtained by a range of technologies such as FIB-SEM, X-Ray, SEM and helium ion microscopy.

ORS Dragonfly Pro provides an intuitive, full and tailored toolkit utilized for visualization and analysis of large 3D grayscale data and it is available solely via ZEISS. Dragonfly Pro enables navigation, annotation and creation of media files, such as video production, of their 3D data. Execute image processing, segmentation and object analysis to measure their outcomes.

Image Credit: Carl Zeiss Microscopy GmbH