When design engineers work with General Plastics, we often delve straight into the technical details of the intended application and our polyurethane materials. Together, the two parties discuss compressive and shear strengths, density, maximum temperature, and other application requirements. Once all that time and effort is spent narrowing down the right material for the application, who will now be responsible for turning the raw material into a final product?

Saving Time and Money with Production Services

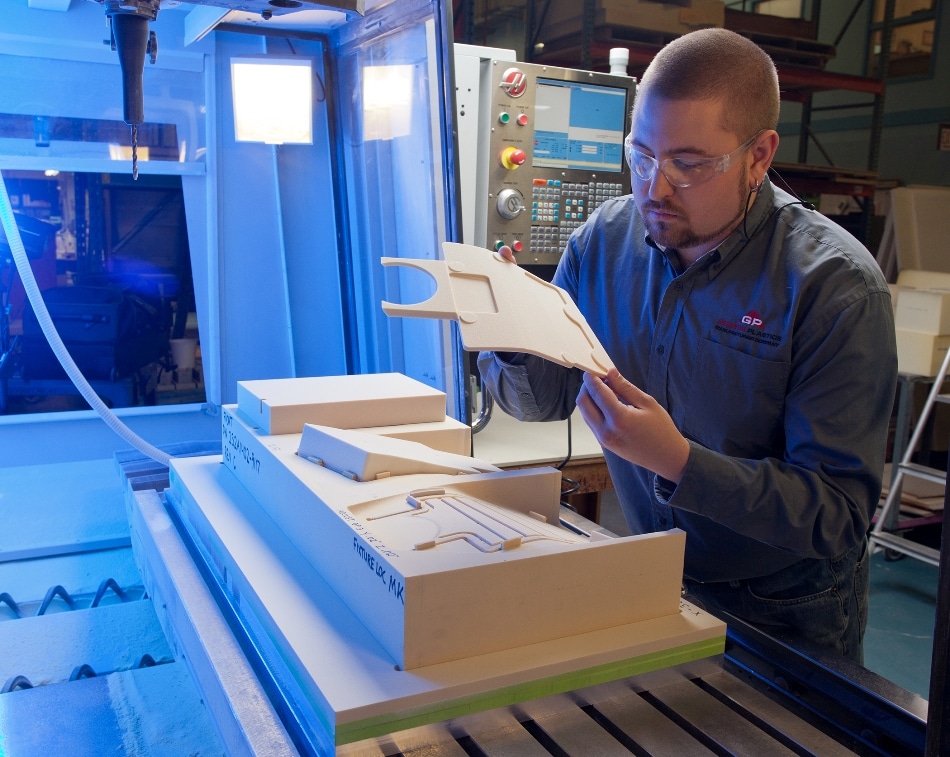

Not only does General Plastics produce premier polyurethane foams, but we also machine, fabricate, and assemble finished components. It makes sense that the original manufacturer is the most knowledgeable about how to process its own materials. Plus, using a one-stop shop simplifies many areas in the supply chain – fewer vendors to manage, reduced shipping costs, less room for error, and more time saved overall. A perfect example is a garage door manufacturer that we recently we began supplying material for. Because of our machining and sanding services, we were able to deliver not only the raw material but the completed parts in the quantities they needed. This allowed them to remove several in-house finishing operations and save money in the overall cost of goods sold.

Another of our customers making underwater floatation devices with General Plastics materials decided to utilize our fabrication services as well. Now that we’re machining, painting, and finishing the floatation planks for them, their supply base was consolidated from three vendors to just one. This simple change successfully decreased their lead times by 50% and reduced costs by 33%.

The Specialty Skills of a One-Stop Shop

Switching to a single-supplier solution requires that the vendor of choice have a wide range of specialized skills. For instance, General Plastics not only offers a variety of in-house production services (such as machining, molding, and tooling), but we also have the knowledge and experience to source, bond, and assemble dissimilar materials and components that may be difficult to integrate well. In addition, we have the ability to create custom formulations, shapes, and details to meet stringent specifications.

Because of our capabilities, a medical components company decided to work with us to manufacture one of their products. They had performance issues with their previous supplier and wanted to find a new vendor with a reputation for excellence. We reviewed their material requirements together, provided feedback and support, finished the components entirely in-house, and delivered them on time as promised. The customer was so satisfied with the results that they have since requested we take over the manufacture of more products to further streamline their supply chain. Now that quality and quantity are no longer an issue, they can focus on pursuing more opportunities than before.

Customers are often surprised to find out we can do more than just make foam. After more than 75 years of developing fabrication services, specialty skills, and key industry relationships, our business is uniquely positioned to make your products a reality. To learn more about how General Plastics can simplify your supply chain, read our article Dealing with Supply Chain Inefficiencies for Composite and Polyurethane Materials.