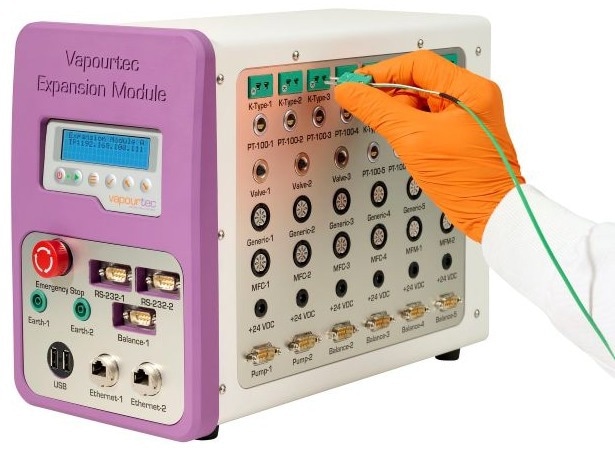

Vapourtec has recently unveiled their Reaction Controller and Datalogger Module which improves the automation of flow chemistry experiments by enabling automated control and logging when using third-party pumps, recirculators, flow meters, sensors and balances.

Image Credit: VAPOURTEC Ltd

Designed for use in chemistry and chemical engineering, the module builds on the capabilities of Vapourtec’s existing flow control software while enabling entry to pilot and production scale environments.

Improving reaction control and enhancing the coverage and accuracy of data can directly impact the quality of reaction outcomes, improving safety, yield and throughput.

The module delivers seamless control of third-party pumps; liquid or gas delivery via serial or analogue mass flow controllers; and fluid flow via switched low voltage connection to valves, all without the need of reprograming every time the configuration changes. It can also measure gas or liquid flow through serial or analogue connection to mass flow meters; mass via serial connection to industry leading laboratory balances; temperature (using PT100 sensors and/or thermocouples); and pressure via analogue devices.

Vapourtec Managing Director Duncan Guthrie explained: “Important applications for the reaction controller and datalogger include interfacing with process or laboratory equipment from different suppliers, automation of a single reaction or a series of sequential reactions, logging key process parameters and data to facilitate process improvements.

“The module eliminates time-consuming tasks, like programing and manual data recording while presenting results for rapid analysis and reporting.”