- The new Stressometer Low-Force Flatness System enhances process control and yield, offering high accuracy and robustness in cold rolling mill applications

- Solution aimed at processes producing ultra-thin aluminum, copper, and steel foil

- Solid mechanical design minimizes maintenance and offers lowest cost of ownership

ABB has launched an advanced low-force system for cold rolling mill applications. Aimed at processes producing ultra-thin metals including aluminum, copper and steel foils, the new Stressometer Low-Force Flatness System combines high accuracy with a robust design and a low total cost of ownership.

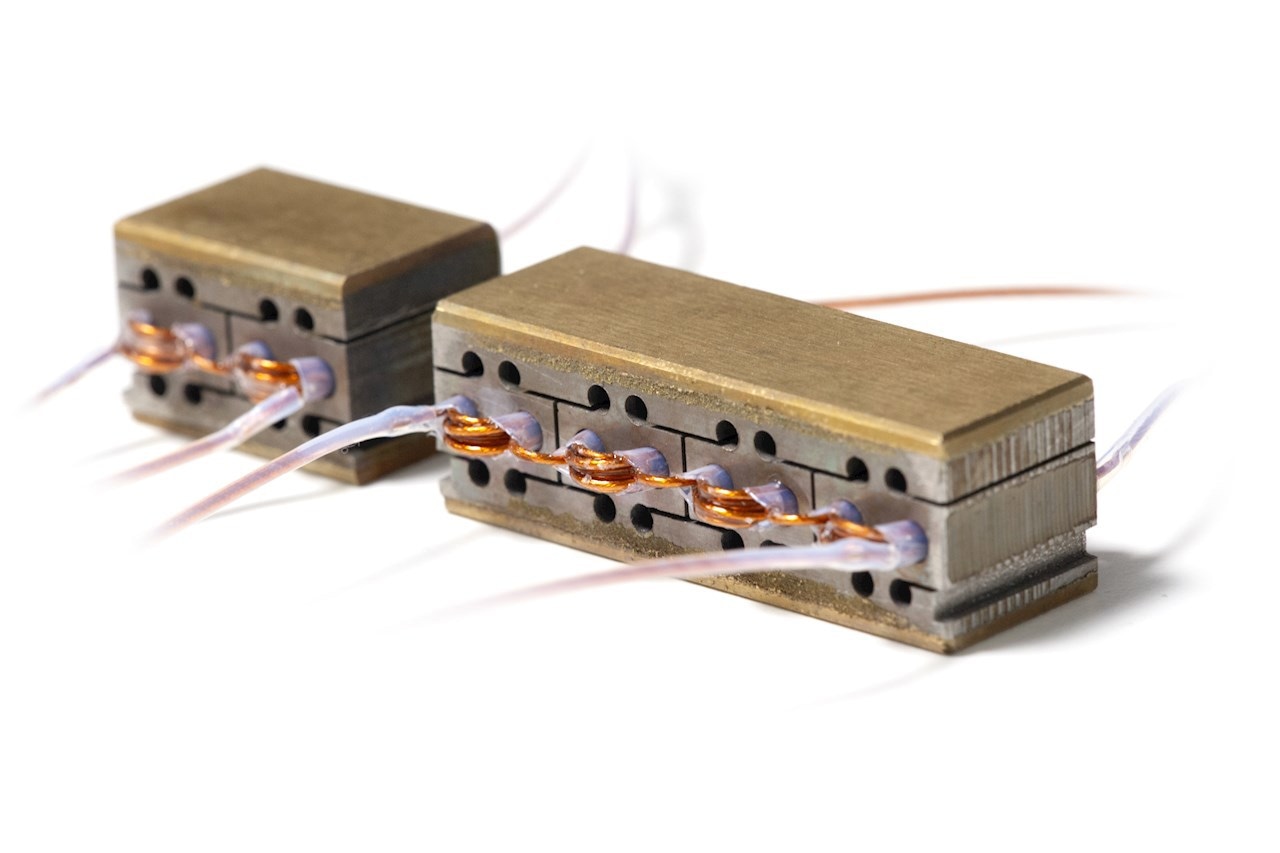

The new Low-Force System sensor.

Image Credit: ABB Inc.

Fitted into a compact 200 mm diameter roll, the low-force system maintains the physical footprint of ABB’s standard Stressometer® sensor while integrating specialized material properties to detect extremely small force variations to within a few grams with unmatched resolution. This enables much tighter flatness, thickness and tension control in finishing applications handling foil gauges ranging from 50 down to five microns.

The Stressometer Low-Force Flatness System is ideally suited for finishing mills and integrated lines handling both breakdown and finishing passes. Its high performance enables precise control where standard force sensors become noisy or inaccurate, particularly below 20 microns. By ensuring consistently high quality, it enables producers to maintain high throughput whilst reducing scrap and re-processing.

"The new system addresses customer requests for solutions that will help them improve quality, yield and energy efficiency in their metals production processes," said Marko Sydanlammi, Global Portfolio Manager, Force Measurement at ABB’s Measurement & Analytics division. "Our new low-force system offers the performance needed to meet these demands, even in the most challenging foil applications, while ensuring durable performance and lowest lifecycle cost."

Demand for ultra-thin metals is growing as companies across sectors including electronics, automotive, aerospace and medical device manufacture look for new ways to produce smaller, lighter and more durable products and components. By enabling tighter control of cold rolling processes, the low-force system allows operators to ensure their products are consistently produced to the right requirements.

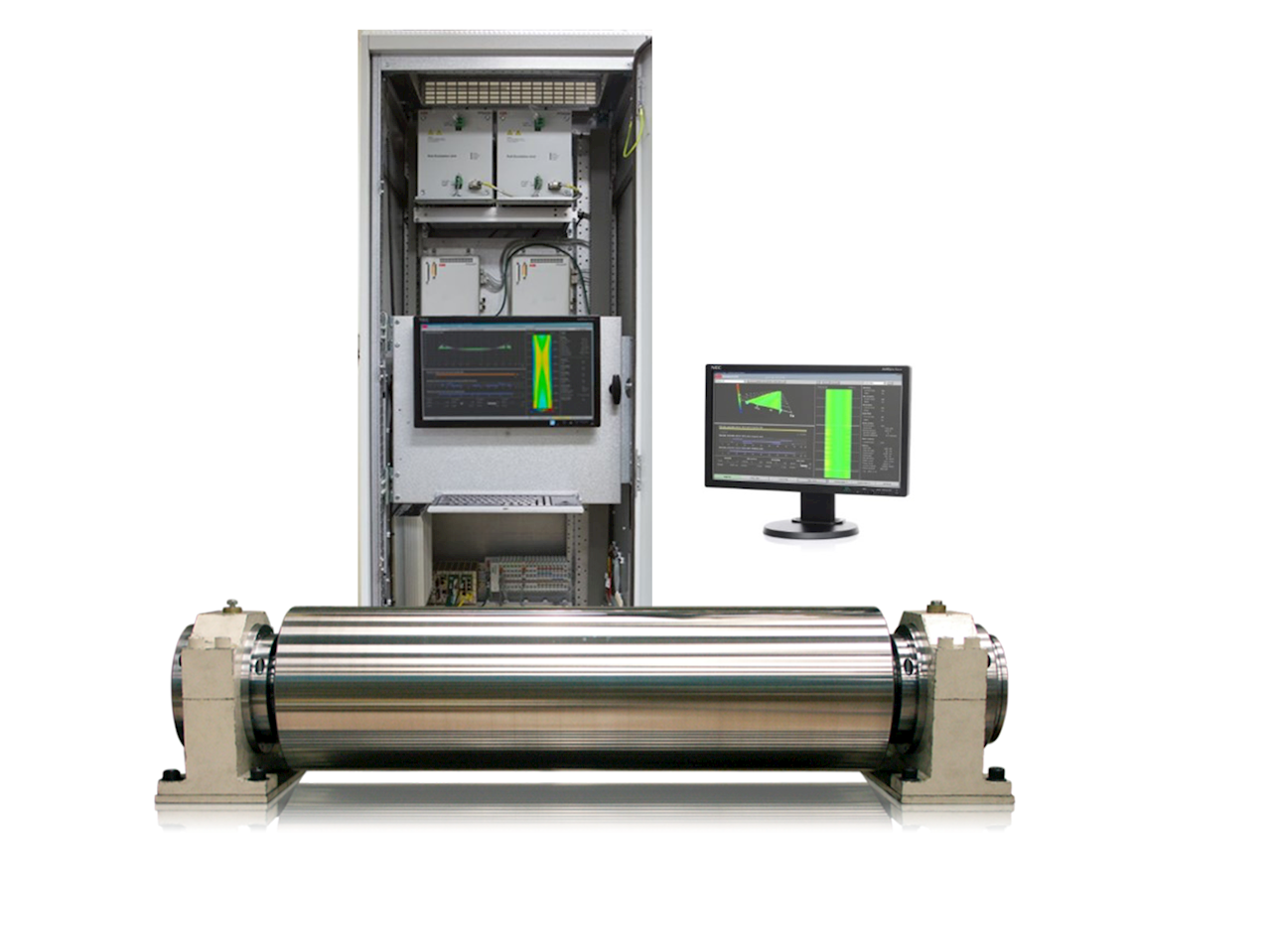

ABB's Stressometer system.

Image Credit: ABB Inc.

In contrast to other sensor technologies, ABB’s low-force system features a solid mechanical design requiring minimal utilities input and virtually no wear-related maintenance. This provides improvements in lifetime performance and accuracy under temperature variation, as well as saving energy by reducing compressed air consumption.

The performance of the system has already been proven in pilot projects, including EV battery manufacturing in South Korea and specialty foil mills in Europe and Asia.

By extending the measurement range to meet the demands of foil applications, the new low-force system strengthens ABB’s portfolio and supports ABB’s drive to help industries outrun – leaner and cleaner.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation