ZEISS Xradia CrystalCT is the cutting-edge microCT for interpreting the materials’ crystallographic and microstructural secrets. It is the first to combine the power of computed tomography with the capacity to prove crystallographic grain microstructures, revolutionizing the way in which polycrystalline materials (such as metals, additive manufacturing, ceramics and other materials) are studied, leading to new and deeper insights into materials research.

- Determine the properties of metals, alloys and ceramics

- Ground-breaking diffraction scanning modes advance materials evaluation and discovery

- At increased throughput, map bigger volumes and a wider range of sample shapes

- Perform 3D non-destructive grain morphology mapping

- To construct high-fidelity computational models, achieve higher sample representivity

Highlights

DCT for an Expanded Range of Research Possibilities

Xnovo Technology and ZEISS Research Microscopy Solutions have teamed up to bring breakthrough laboratory diffraction contrast tomography (DCT) capability to market.

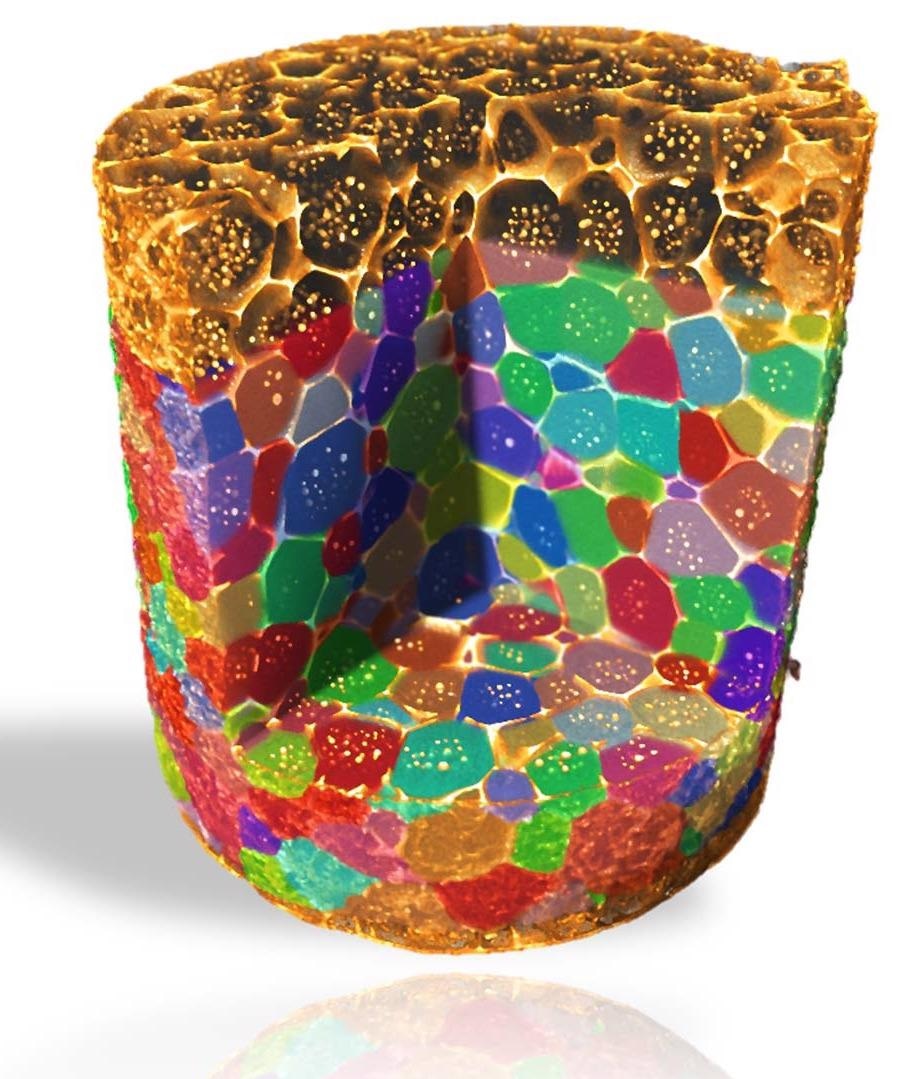

DCT on a microCT, which uses 3D grain mapping, allows technical and industrial research laboratories to image single-phase polycrystalline materials in 3D, encompassing a wide range of metal, ceramic, mineral, semiconductor and pharmaceutical samples.

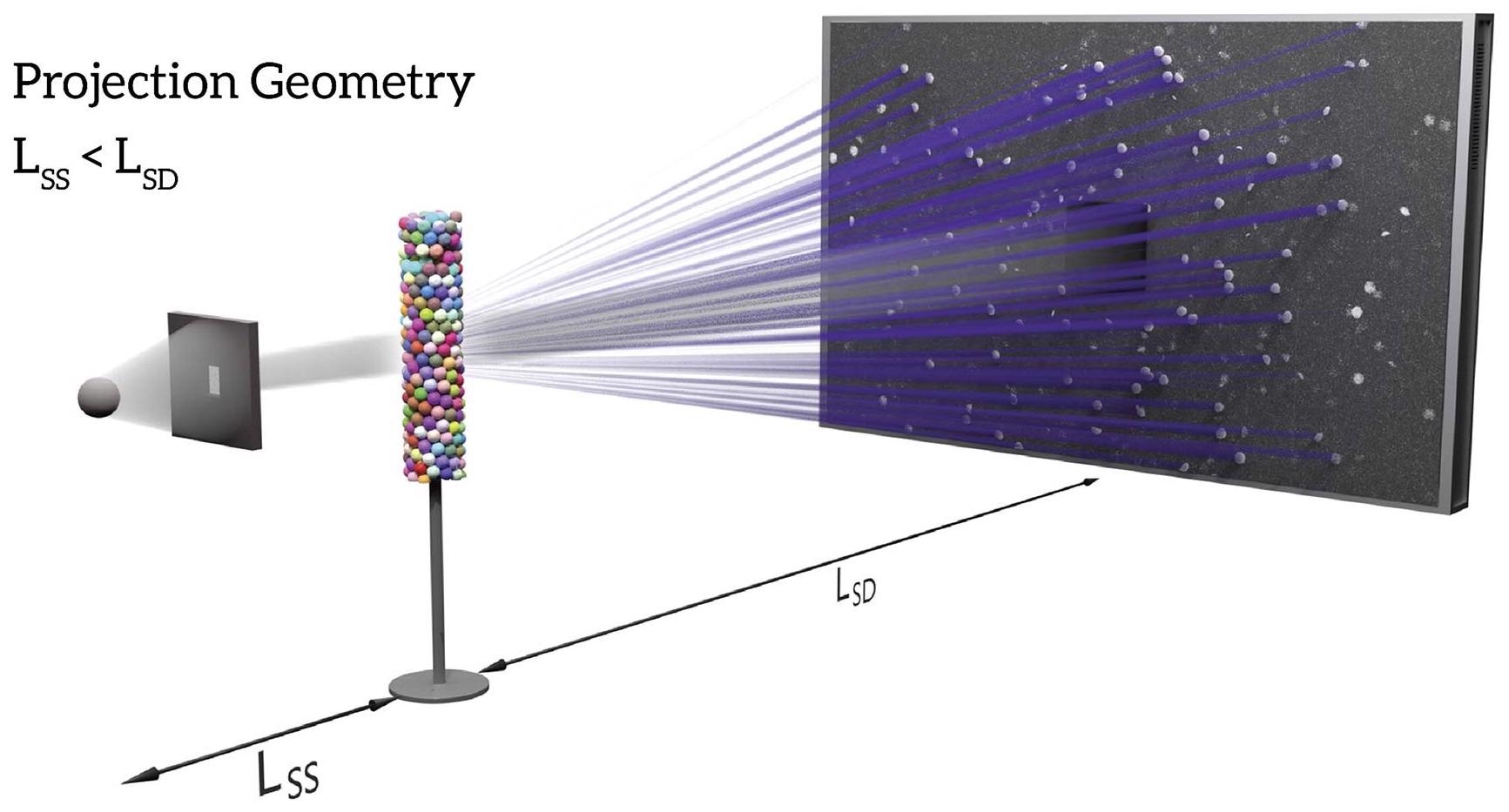

The ZEISS Xradia CrystalCT comprises precisely engineered aperture and beam stop components that were created specifically to harness divergent, polychromatic X-Ray beams to spotlight a region of interest and boost sensitivity to weaker diffraction signals of polycrystalline objects.

Innovative DCT collection modes eliminate sample size limits, allowing users to investigate a wider range of sample types. Scanning samples quicker and with more precise data representation is possible with seamless high-volume grain mapping.

Schematic illustration of CrystalCT projection geometry. CrystalCT delivers dual modalities: absorption contrast tomography (ACT) and diffraction contrast tomography (DCT). Image Credit: Carl Zeiss Microscopy GmbH

Superior Sample Representivity from Advanced Diffraction Scan Modes

Through ground-breaking diffraction scanning modes, ZEISS Xradia CrystalCT enhances materials characterization, modeling and discovery.

- Allows for greater sample volumes to be scanned

- Addresses the issue of sample specificity

- Sample preparation and management of irregular/natural sample shapes are simplified

- Speeds up the process

- Provides unrivaled sample representativeness

These advanced modes solve some of the problems with typical DCT data collection, which assumes that the sample ROI is completely lighted by the aperture field of view (FOV) at all rotating angles. Advanced diffraction scanning modes give helical phyllotaxis schema to address a wide range of sample shapes and sizes, inspired by nature’s golden angle.

Al-4wt%Cu sample with gauge section dimension of (length) 1.25 mm, (width) 1.0 mm and (thickness) 0.5 mm. Sample scanned using helical phyllotaxis HART. Image Credit: Carl Zeiss Microscopy GmbH

A Powerful MicroCT Platform

On a microCT, ZEISS uses its robust Xradia technology to achieve world-leading performance. Users can get high-quality, high-resolution scans with best-in-class contrast using a powerful stage, flexible software-controlled source/sample/detector placement, and a huge array detector.

To expose inner elements in their complete 3D setting, capture whole items or gadgets. Faster acquisition rates allow users to control more samples in less time, boosting overall productivity and profits.

In situ and 4D investigations using non-destructive CT are also possible to determine the practical impact of changing environments over time. The ZEISS Xradia imaging system blends a tried-and-true hardware design with cutting-edge drift and stability capabilities.

CrystalCT routinely exceeds one’s understanding of what a microCT is due to the higher stability of this recognized platform.

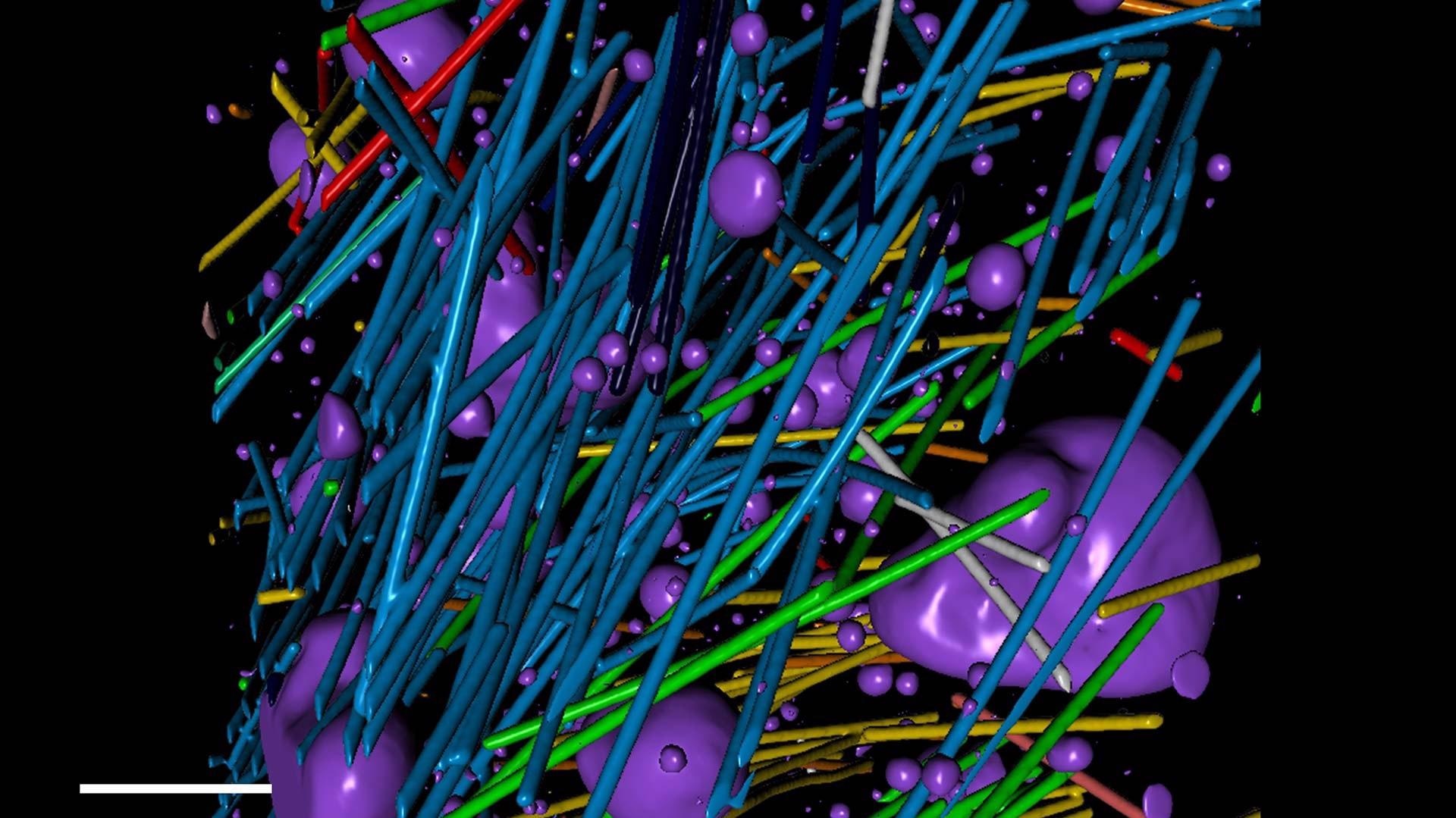

Quantitative volumetric analysis of a steel-reinforced concrete specimen. Voids are rendered in purple. Image Credit: Carl Zeiss Microscopy GmbH

Fields of Application

ZEISS Xradia CrystalCT is a cutting-edge, dramatically new diffraction scanning technique that allows users to map grain boundary surfaces in their original condition across substantially greater volumes while targeting realistic sample shapes that meet the needs of research and industrial laboratories.

DCT allows for non-destructive 3D grain imaging, unlike previous grain mapping methods.

Material Science

- Surface imaging technologies, such as optical or scanning electron microscopy, do not reveal non-destructive insights into internal microstructures or overlay grain maps

- Ex situ or in situ investigations using 4D imaging to examine how materials develop, such as through mechanical load or corrosion

- Ability to separate and analyze data to provide quantitative, three-dimensional representations of structures and particles

- High-resolution absorption contrast tomography and non-destructive 3D grain imaging provide additional information on size, shape, orientation and grain boundary

3D grain map of aluminum-copper alloy imaged in absorption and diffraction contrast tomography. Image Credit: Carl Zeiss Microscopy GmbH

Metals and Minerals

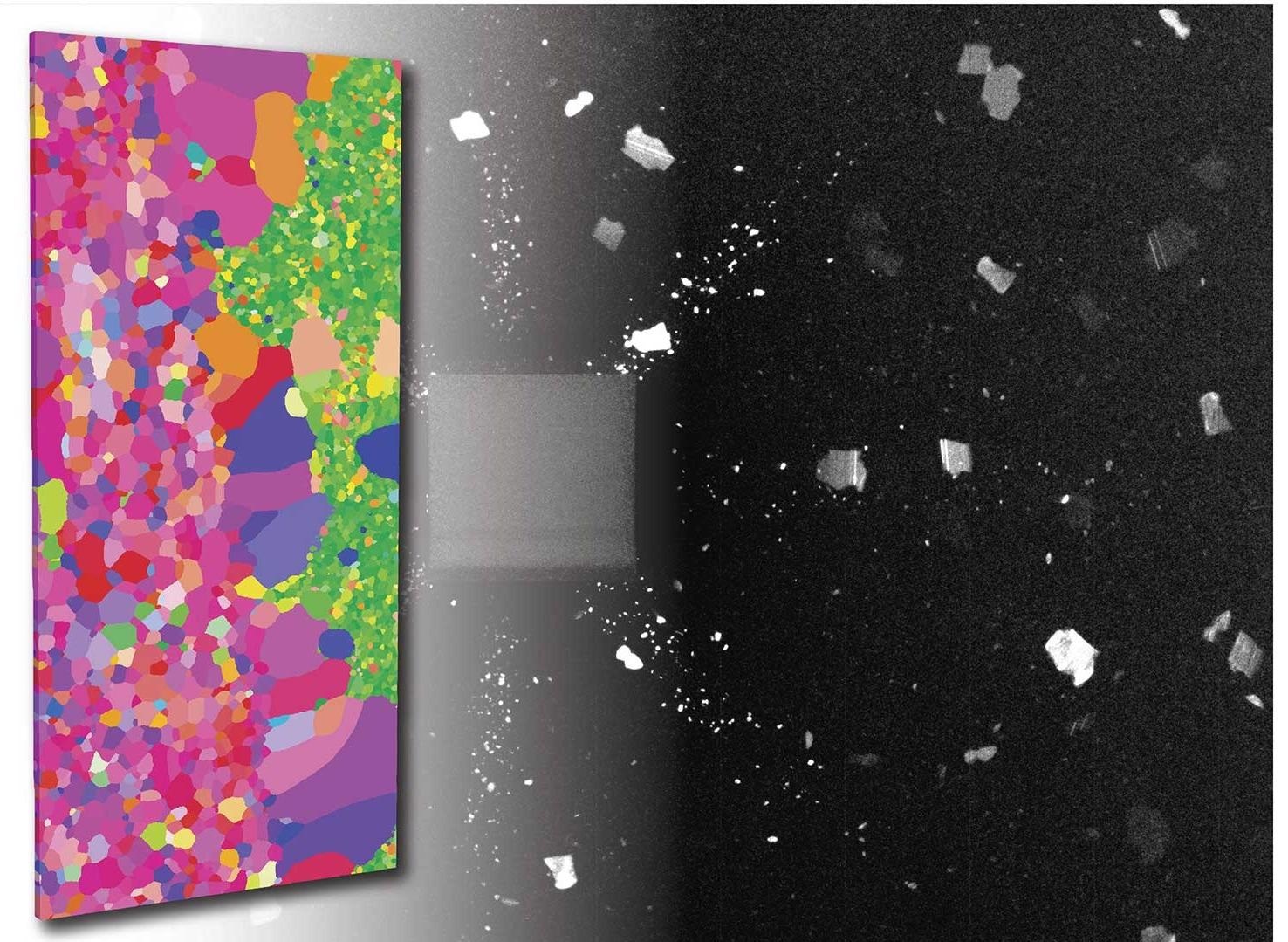

- To get knowledge into alloy performance and its influence on thermal and mechanical processes, study grain size and phase evolution in 3D

- In situ flow investigations or 3D mineralogy need high contrast 3D imaging

- Estimate materials properties (thermal, mechanical, etc.) or digital rock simulations utilizing non-destructive 3D tomography data imaging, characterization and modeling of rock cores (up to 4") with high throughput

3D grain map of an ultra-thin oriented electrical steel sample with dimension of (RD) 4 mm, (TD) 2 mm and (ND) 0.08 mm. Image Credit: Carl Zeiss Microscopy GmbH

Manufacturing

- Assess the print quality of 3D printed metal items using crystallography

- Physical cross-sectioning can be used to supplement or replace physical cross-sectioning, removing the need to sacrifice the sample

- Scanning of intact devices with high throughput and with a short time to findings

- Create a range of sample sizes, including huge objects in their complete 3D environment, with 3D grain maps for specialized applications

3D grain map of polysilicon materials from a solar panel with height of 30 mm. Image Credit: Carl Zeiss Microscopy GmbH

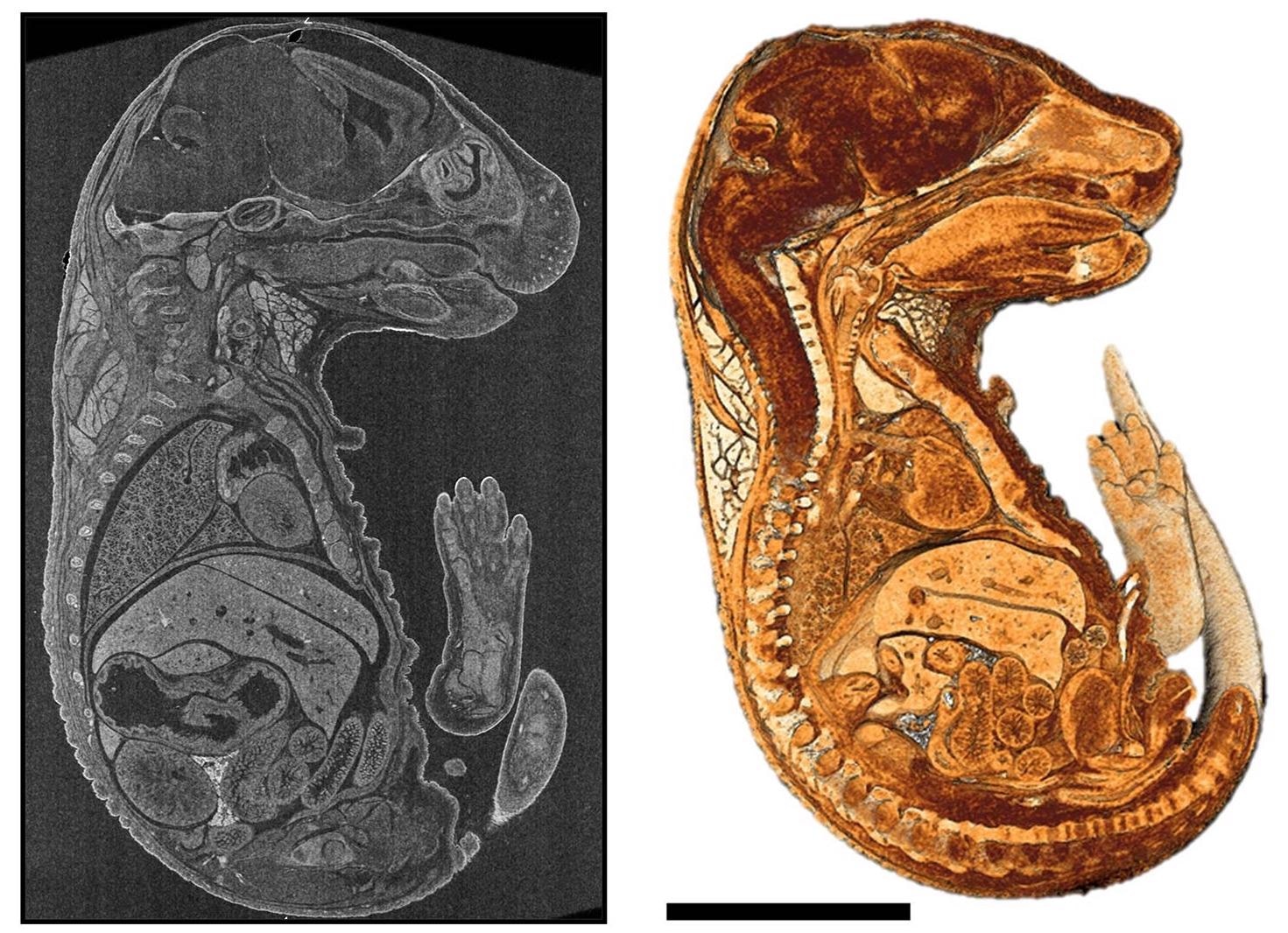

Life Science

- 3D electron microscopy allows for quick, non-destructive evaluation of sample staining and feature positioning for future imaging

- With high contrast imaging, either stained or unstained hard and soft tissues, as well as biological microstructures

2D virtual cross-section and a cutaway view of 3D rendering of a mouse embryo embedded in paraffin. Image Credit: Carl Zeiss Microscopy GmbH