Optical profilers provide precision 3D measurements and are used by numerous industries. Various designs provide distinct strengths and weaknesses.

In this article, KLA's patented ZDot™ optical profiling technology is compared to white light interferometry.

White Light Interferometry (WLI)

Several industries use the white light interferometry (WLI) for 3D measurements. WLI is designed to determine surface heights ranging from nanometers to millimeters. The key benefit offered by WLI over other optical methods is that the vertical resolution is autonomous of magnification or field of view, which makes it suitable for applications requiring low topographic features on even, flat surfaces. However, there are some major flaws for 3D optical profiling of complex surfaces possessing a variety of topographic features.

WLI instruments are prone to sample tilt and vibration. The imaging capability of WLI is restricted because of the low light throughput design of the optical system. Therefore samples possessing variations of large height, multiple layers, high roughness, low reflectivity, or large reflectivity cannot be handled by WLI instruments.

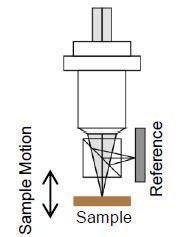

Figure 1. Michelson Interferometer

ZDot™ Optical Profiling Technology

ZDot™ optical profiling technology is capable of solving the challenges related to the WLI with an optical design that provides high light throughput and is intrinsically insensitive to sample tilt and vibration. It provides unparalleled metrology capability for challenging R&D and production applications in advanced semiconductor packaging, high brightness LED, microfluidics, solar cell etc.

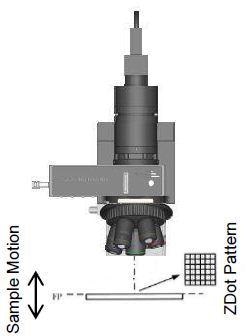

Figure 2. ZDot™ KLA

Comparison

It is crucial for surfaces possessing low reflectivity or high aspect ratio features, such as vias or deep trenches, to have high light throughput and optical efficiency. Optical profilers built according to WLI offer only restricted light throughput because of their optical design (Figure 1). The illuminating light is divided between the reference mirror and the sample, thus restricting the light available for metrology and imaging. Zeta-20 Optical Profilers built according to ZDot™ technology are designed to overcome this restriction by using the same optical path for both focusing and imaging (Figure 2).

Vibration sensitivity in WLI is due to the dividing of the illuminating light into two separate optical paths. Even minor vibration tends to create relative motion between the sample and the reference mirror (Figure 1), thereby greatly decreasing vertical measurement resolution.

Likewise, sample tilt flaw in WLI causes the interference fringes to be narrow, thereby further decreasing vertical resolution of interferometers. ZDot™ is capable of overcoming both of these challenges with its unique optical design. It uses a common path for focusing and imaging and a patented and proprietary technique for sensing the focal plane.

ZDot™ consists of a confocal grid structured illumination (CGSI), which can produce contrast that is autonomous of the sample, thereby enabling sturdy z-height measurements on nearly every surface. This optical design makes Zeta-20 Optical Profilers intrinsically insensitive to both vibration and sample tilt.

Additional Advantages of a Zeta-20 Optical Profiler

Other benefits of the profiler are:

- True color imaging – WLI is false color

- Lower cost – using standard objectives

- Extendible functionality (optional): Interference contrast imaging (ZIC); Film spectrometry (ZFT); Interferometry (ZX5, ZSI)

Applications Possible Only with ZDot™ Technology

The figures show the applications possible with ZDot technology:

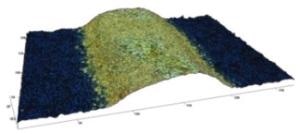

Solar substrates and devices

Zeta-20 Optical Profilers show true film colors and can handle dissimilar materials in the same field of view.

|

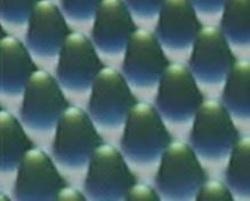

LED processing

Characterization of patterned substrates – WLIs get confused by repeating patterns

|

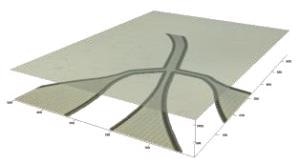

Surfaces with high slope

ZDot™ can image surfaces with high slope such as the chamfer and side wall of a wafer – not possible with WLI.

|

Microfluidic devices

ZDot™ can image buried layers with transparent and low contrast surfaces – not possible with WLI.

|

This information has been sourced, reviewed and adapted from materials provided by KLA Corporation.

For more information on this source, please visit KLA Corporation.