Vitrek, a US-based manufacturer of high-precision test and measurement equipment, offers the 95X Series hipot tester with 100 pico-amp leakage current resolution for detecting micro-level insulation defects in safety-critical industries. Designed for medical devices, aerospace avionics, and high-reliability electronics, the Vitrek 95X Series ensures that early-stage insulation degradation is detected before catastrophic failures occur.

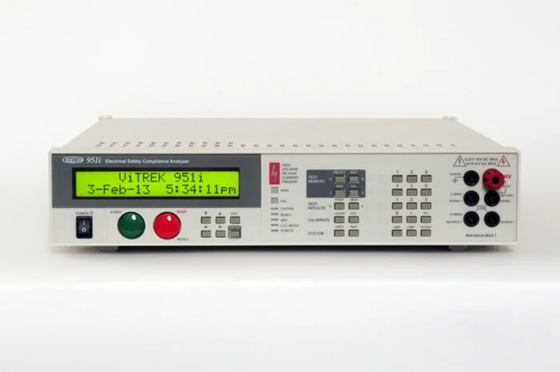

Image Credit: Vitrek

Image Credit: Vitrek

Why 100 Pico-Amp Resolution Matters

A hipot tester works by applying high voltage to a device under test and measuring how much electrical current leaks through its insulation. In medical implantable and aerospace avionics, allowable leakage limits are exceptionally tight. The 95X Series detects currents as low as 0.0001 milliamps, catching insulation degradation at stages that conventional equipment simply cannot register.

The 95X Series also delivers insulation resistance measurements up to 6 tera-ohms, which is a unit equal to one trillion ohms. This range is critical for validating ultra-high impedance insulation systems found in precision instruments, where even a small resistance drop signals a serious issue. Its dual Digital Signal Processor (DSP) and dual Coldfire microprocessor architecture further enhance measurement stability, providing reliable pico-amp measurements even in noisy environments.

Meeting Medical and Aerospace Compliance Standards

The 95X Series supports compliance testing against two widely referenced standards. IEC 60601-1 governs the safety of medical electrical equipment and sets patient leakage current limits as low as 0.01 milliamps. DO-160, maintained by RTCA, defines environmental testing requirements for aircraft equipment. The 95X also includes a 400Hz AC voltage test mode, which matches the frequency used in aviation electrical systems and provides more accurate dielectric analysis of avionics components.

Early Detection Through Accelerated Life Testing

"The gap between 100 nanoamps and 100 picoamps is where early-stage insulation failure occurs," said [Executive Name], [Title] at Vitrek. "For medical device and aerospace manufacturers, finding that failure before it reaches the field is not a nice-to-have; it is a baseline requirement."

In accelerated life testing, the 95X Series detects insulation weaknesses 6-12 months earlier than conventional testers by stressing components with heat and humidity to simulate years of use.