Bio-feedstocks present a viable alternative to crude oil for the production of fuels. As with conventional fuels, these biofuels need to comply with the most stringent limitations that are in place for fuel emission regulation. Regulations around the world, including the American Tier III, European Euro 6, and the Indian Bharat VI, dictate limits of sulfur pollution that can be released during the combustion process.

Introduction

Nitrogen-containing compounds are often tolerated in oils and refined products because fuel specifications do not directly limit the nitrogen content of transportation fuels. The nitrogen content and the properties of nitrogen-containing compounds present in fuel are indirectly regulated through fuel specifications such as gum content, storage stability, and thermal stability. Besides the environmental impact, the presence of both sulfur and nitrogen-containing compounds also impose limitations on process operation, catalyst selection, and process development for oil upgrading and refining. In some cases, the presence of species may require on-purpose pretreatment steps and even specialized process workarounds.

Generally, biodiesel produced using vegetable oil contains less sulfur than conventional diesel. However, with the evolution of the biofuel industry, where waste fats, oils, and greases are now being used as bio feedstock, the quality can also differ greatly. The more varieties of feedstock you have, the more analytical information is required for good process control.

Hydrotreatment or hydrocracking is a process used after the pretreatment steps to upgrade the bio feedstocks into biofuels. This process not only converts the relatively large and complex molecules into molecules of the size and boiling point range of conventional fuels, but it is also used for the removal of heteroatoms including sulfur (S) and nitrogen (N). The analysis of these species in the feedstocks is used to control the treatment process and determine content in the final product. Final product testing is required for eventual product release.

Measuring Sulfur & Nitrogen In Biofuel Products

Analysis of total sulfur and nitrogen content in biofuels by combustion technology and ultraviolet fluorescence (UVF) and chemiluminescence (CLD) detection has become the standard method to characterize feedstock, intermediate streams, and finished products due to its linearity, sensitivity, ruggedness, and dynamic range.

PAC’s Antek ElemeNtS analyzer was developed to meet the need of the industry by measuring total sulfur and total nitrogen at ultra-low levels in liquids, gases, and LPG samples. The modular design allows simultaneous analysis of sulfur and nitrogen in a single run while reaching detection limits as low as 20 ppbw and delivering long-term stability for reduced calibration requirements. With excellent combustion characteristics, the analyzer effortlessly combusts the different feedstocks used for renewable fuels.

Figure 1. Antek ElemeNtS total sulfur and nitrogen analyzer equipped with high capacity autosampler. Image Credit: PAC L.P.

A Better Measurement Delivers a Higher Value Product

The Antek ElemeNtS analyzer allows operators to run their refining processes closer to specification due to its precise analysis of total sulfur and nitrogen content resulting in less substandard product quality and costly catalyst poisoning. Other benefits include:

Reliable Data at Trace Levels

One of the most important aspects in determination of sulfur and nitrogen is the reliability of measurement. The data must be trustworthy. Every ElemeNtS analyzer that ships to a customer is fully tested using products similar to what will be analyzed on the instrument, including final products like gasoline, (bio)diesel, lubricants, and jet fuel. This means the ElemeNtS analyzer is calibrated and ready to go at shipment, and the results produced by the analyzer can be verified in the customers’ own labs and validated using reference samples.

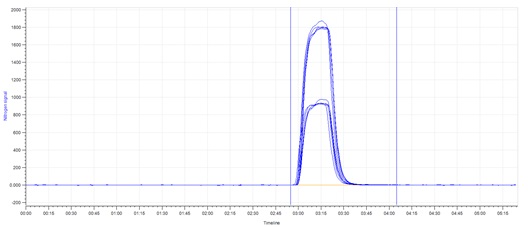

The combustion characteristics - which are important for reliable data - allow repeatable analysis of even the most complicated sample matrices. In the case of biofuels, the raw feedstock samples might become challenging for some applications, but for the Antek ElemeNtS, these sample types are no problem.

Figure 2. Repeatable Nitrogen Analysis of Palm Oil Fatty Acid and Tallow Feedstock. Image Credit: PAC L.P.

Stability of Calibration

Calibration stability refers to the length of time between required calibrations. The ElemeNtS analyzer is highly stable and extremely robust. It has a higher stability of calibration, requiring less maintenance and longer time between recalibrations. It translates to better process control, because a wider window of stability decreases the likelihood of unreliable measurements.

Interference Free Analysis

With the increasing demand for biofuels we also see an increase in the use of cetane and octane improvers to boost the combustion characteristics of the final products. Products like this often contain high concentration of oxygen and nitrogen that could both interfere on the analysis of sulfur. Conventional techniques like XRF or X-ray always require correction of the sulfur result based the products oxygen content, which in turn requires an additional analysis on the product to get an accurate result. The UVF technology used in the ElemeNtS does not require such correction.

As described in the standard test method D5453 for the analysis of total sulfur in light hydrocarbons, the UVF technology can experience interference caused by the presence of bound nitrogen containing components, when present in sufficiently high concentrations. The Antek ElemeNtS analyzer has a solution in place that allows nitrogen interference-free analysis in both the single and dual channel instrument configuration, by use of a dedicated interference kit.

Conclusion

Producing renewable fuels from the wide variety of feedstocks currently available requires more and more analytical information to control the refining processes. The presence of sulfur and nitrogen species is known to create sub-quality products, costly catalyst replacement, and environmental pollution making it important parameters to be analyzed before, during and after the production of fuels. PAC’s Antek ElemeNtS analyzer was developed to meet the need of the industry by measuring total sulfur and total nitrogen efficiently – in a single run – at ultra-low levels in liquids, gases, and LPG samples without sample specific interference.

This information has been sourced, reviewed and adapted from materials provided by PAC L.P.

For more information on this source, please visit PAC L.P.