The doughLAB is a flexible dough rheometer that features a conventional z-arm mixing action.

The instrument employs a range of standard and custom test configurations to determine a sample’s water absorption, development time, dough mixing profile and stability. It can also measure the softening of wheat, durum, rye and composite flours for baking, milling and foods laboratories.

Image Credit: PerkinElmer Food Safety and Quality

It is ideally suited for:

- High speed mixing that matches industrial mixing

- Suitable for extremely strong samples or flours that are hard to develop

- Standard method for studying characteristics of samples (ICC Standard No. 184 and AACC Method 54-70.01)

Description

The doughLAB’s speed control and variable temperature capability permit the testing of samples that are generally challenging to handle. This method follows ICC and AACC Methods and describes an enhanced process for testing flour samples using the doughLAB.

It is possible to attain more accurate and process-relevant results in a shorter time compared to traditional testing methods by using a faster mixing speed.

Samples can be tested for peak (development) time, stability, softening, water absorption (WA), mixing tolerance index and other parameters.

The method can be applied to any flour, including, but not limited to, whole meals and formulations, rye flours and wheat. This method is particularly suited to assessing flour that is difficult to develop, or that is extremely strong.

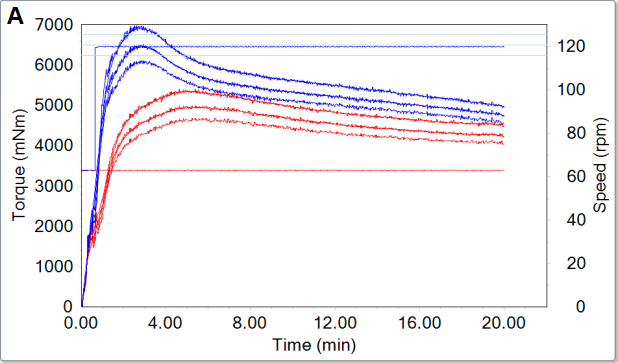

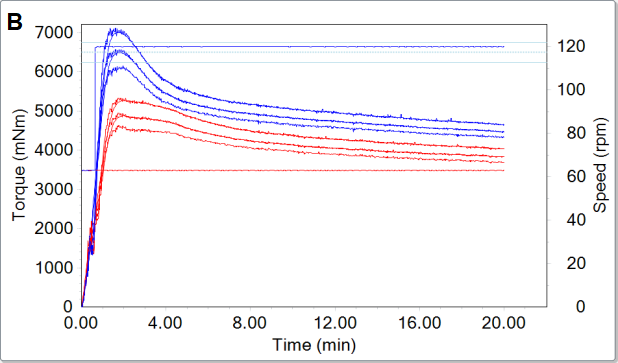

Figure 1. doughLAB curves of bakers (A) and biscuit (B) flours tested at different speeds: 120 rpm (blue curves, doughLAB standard method) and 63 rpm (red curves, Farinograph method). Results can be obtained more quickly and accurately at higher mixing speeds. Image Credit: PerkinElmer Food Safety and Quality

Method

A 10-minute mixing profile was employed in this study.

Sample Preparation

A total of 300.0 g (or 50.0 g) of sample was prepared at 14% moisture.

The user enters the initial water absorption (WA) estimation, and the doughLAB will automatically dispense an appropriate amount of water based on the sample size. The doughLAB will then calculate the correct WA to reach a peak of 500 FU.

Profile

Source: PerkinElmer Food Safety and Quality

| Time |

Type |

Value |

| 00:00:00 |

Temp |

30 °C |

| 00:00:00 |

Speed |

63 rpm |

| 00:00:30 |

Speed |

120 rpm |

| 00:10:00 |

End |

- |

Premixing time: 60 sec.

Premixing speed: 63 rpm |

Measure

Measurements were conducted as follows:

- PT: Peak torque (mNm)

- Stab: Stability (min)

- WA: Water absorption (%)

- ST: Softening (FU)

- DDT: Dough development time (min)

- MTI: Mixing tolerance index (mNm)

The torque is 1300 mNm for the 50 g bowl, and 6500 mNm for the 300 g bowl. The test can be extended if needed to realize stability or similar results for extremely strong flours.

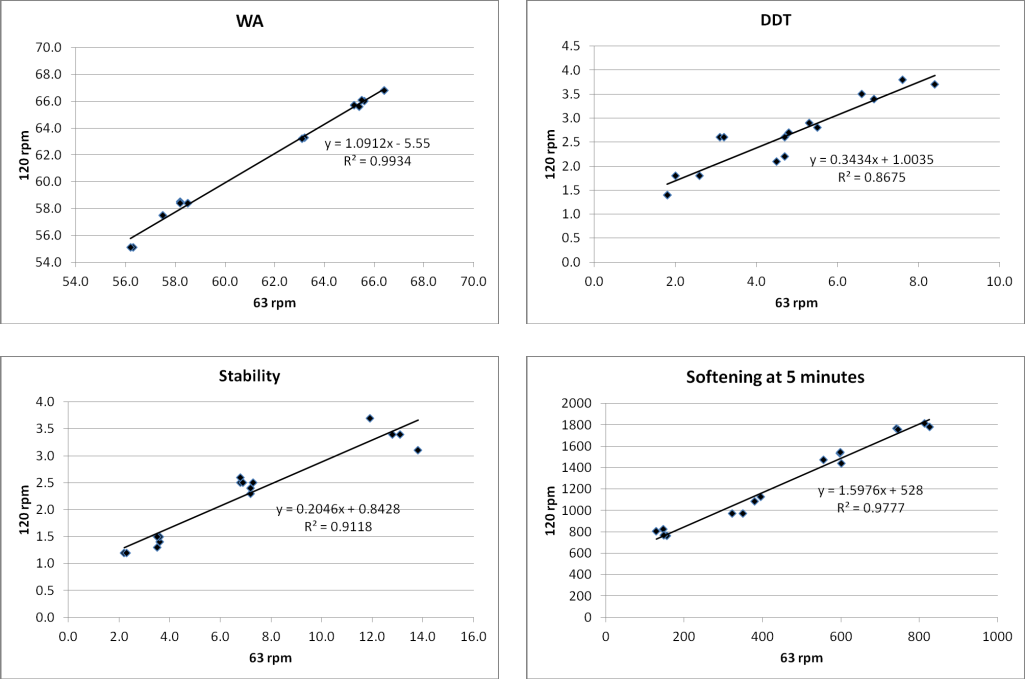

Figure 2. Comparison of dough mixing parameters at different mixing speeds for flour samples ranging in mixing properties. Image Credit: PerkinElmer Food Safety and Quality

Reference

- Cereals & Grains Association. AACC Method 54-70.01. High Speed Mixing Rheology of Wheat Flour Using the doughLAB. Approved Methods of Analysis, CGA, St. Paul MN, USA.

- International Association for Cereal Science and Technology. ICC Standard No. 184. Determination of the mixing quality of wheat flour doughs by high-speed mixing using the doughLAB. ICC Standards, ICC, Vienna, Austria.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.