A comprehensive scanning electron microscopy (SEM) analysis necessitates high-quality specimen preparation.

Traditional mechanical sample preparation techniques, such as grinding, polishing, fracturing, or cutting with scissors or knives, can yield usable results for certain specimens. However, these methods may prove inadequate, particularly for composites and layered structures with varying hardness or brittle materials.

As a result, better techniques are required. This article discusses one such technique: Broad Ion Beam (BIB) Milling.

What is Broad Ion Beam Milling?

BIB milling is a complementary SEM sample preparation technique that employs accelerated argon ions to sputter material from a specimen's surface on a microscopic scale, analogous to macroscopic sandblasting used for cleaning parts.

Since this method does not apply mechanical force that could lead to material deformation or displacement, it produces clean surfaces at the millimeter scale. This reveals the specimen's “true” nature, making it ideally suited for SEM imaging and analysis.

Two primary milling methods are utilized for sample preparation: cross-section milling and flat milling.

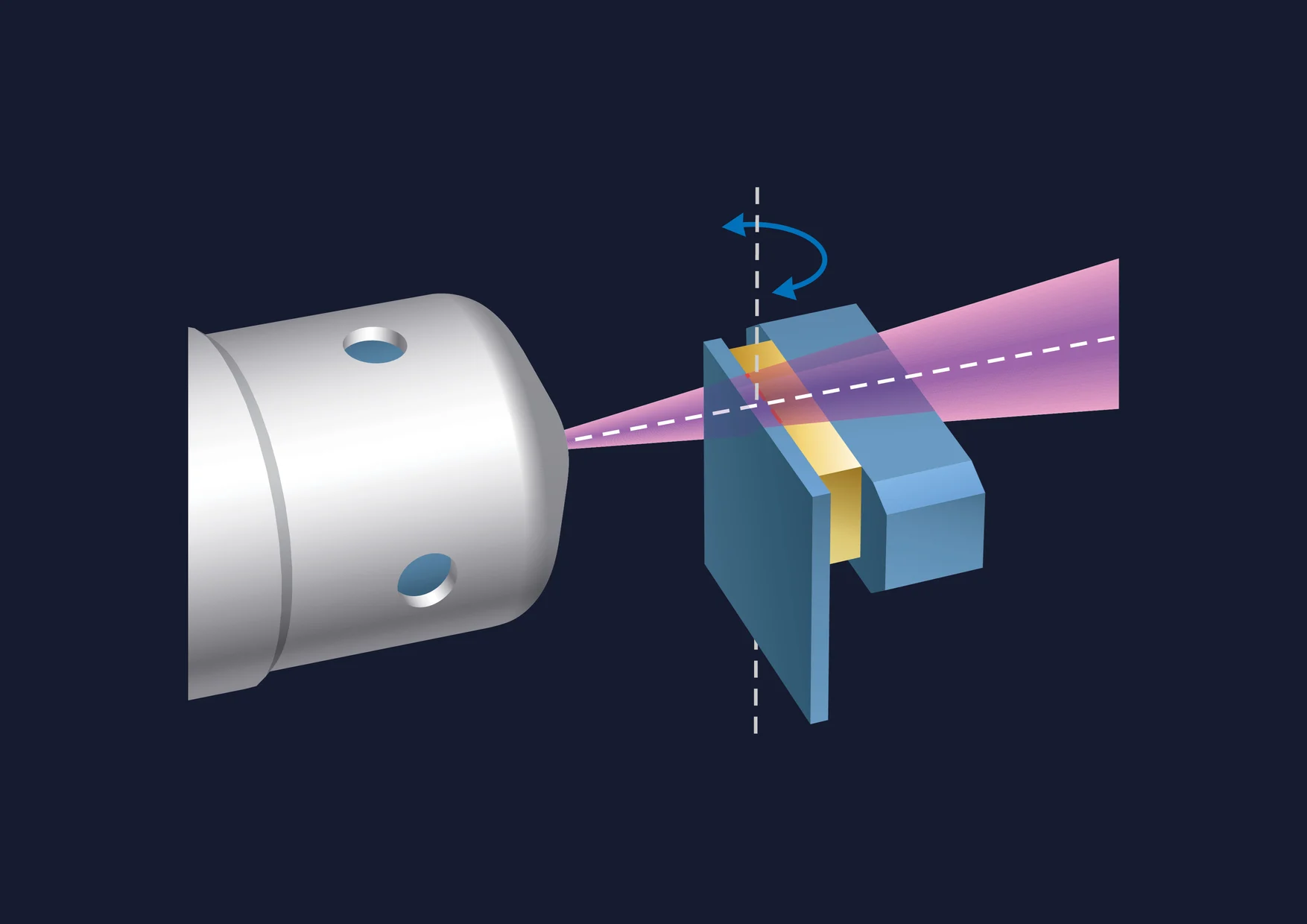

In cross-section milling, a mask is positioned between the ion gun and the sample, exposing part of the sample that extends beyond the mask to argon ion irradiation. This method is particularly effective for preparing complex multi-layered structures that are challenging to polish.

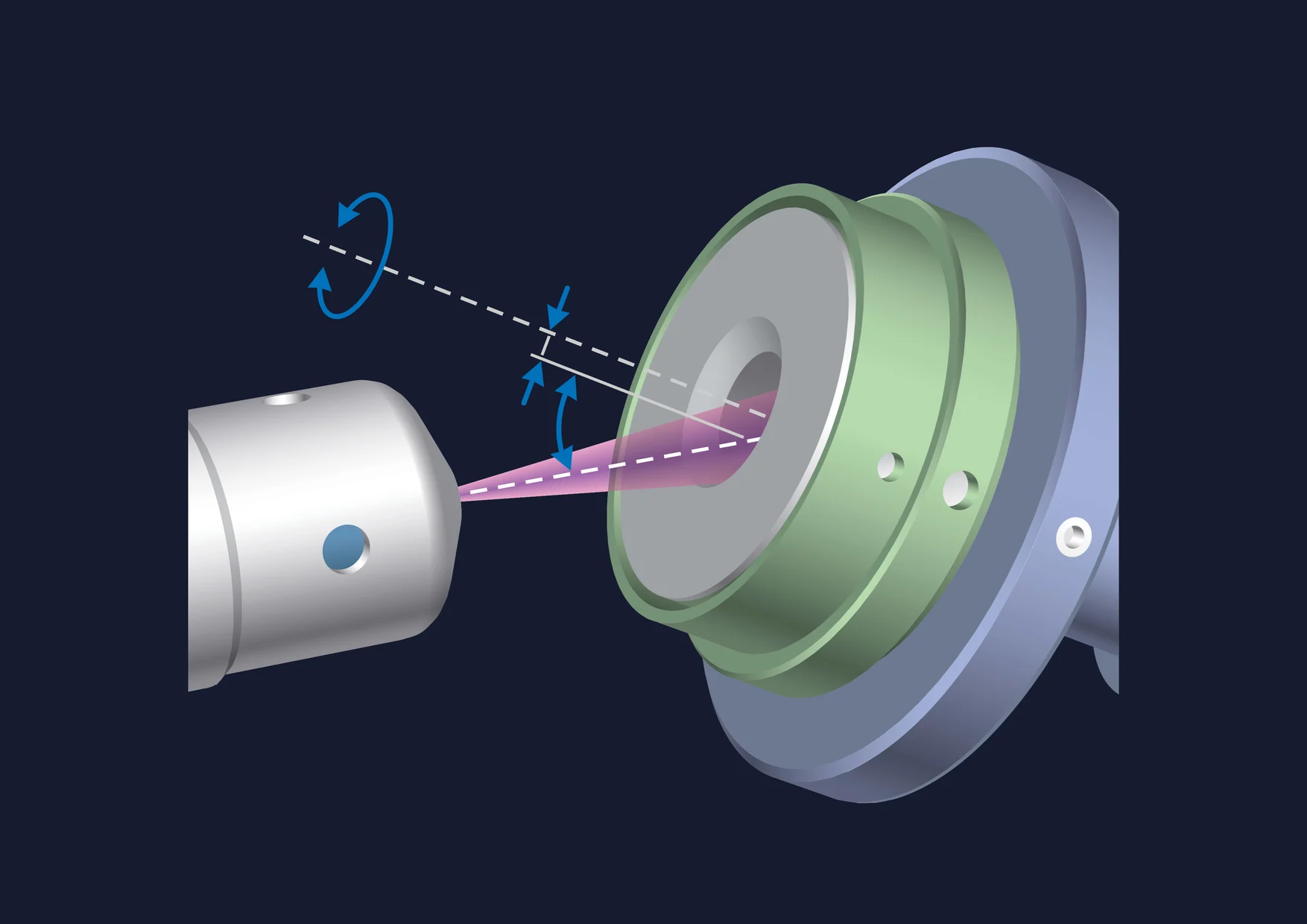

After mechanical polishing, flat milling is typically employed to achieve defect-free and exceptionally smooth sample finishes. Parameters such as ion energy and milling angle can be adjusted to regulate the depth and rate of milling.

The argon beam strikes the sample surface at an angle, allowing a wide sample area to be processed by deflecting the beam’s axis from the sample’s rotation axis.

Both cross-section milling and flat milling offer advantages across various industries, including energy storage and renewable energy, semiconductors and microelectronics, metallurgy, coatings and packaging.

These techniques can be applied in critical areas, such as evaluating active material layer thickness and homogeneity in lithium-ion batteries or assessing thin film properties in the coatings industry.

Figure 1. Cross-section milling. Image Credit: Hitachi High-Tech Europe

Figure 2. Flat milling. Image Credit: Hitachi High-Tech Europe

Combining BIB Milling and SEM Analysis

Hitachi High-Tech provides a diverse product lineup in the electron microscope sector, ranging from compact tabletop SEMs with integrated elemental analysis to conventional large-chamber SEMs, high-resolution field-emission electron source-driven SEMs (FE-SEM) and Transmission Electron Microscopes (TEM) for detailed precise analysis.

Both ion beam sample preparation and SEM analysis tools available in-house enable powerful combinations for specific applications, such as direct tool-to-tool specimen transfer under inert gas conditions.

This capability is crucial for studying oxidation- or humidity-sensitive specimens, such as those from the lithium-ion battery sector.

BIB Milling for a Wide Range of Applications

The ArBlade 5000 platform is modular and offers extensive customization to meet specific application needs. For cross-section preparations, widths can be flexibly adjusted up to 10 mm, temperature-sensitive specimens can be actively cooled, and multiple specimens can be prepared simultaneously for sequential automated processing.

Flat milling provides advantages such as the ability to finish milling with ultra-low ion beam energies, ensuring optimal surface quality for EBSD analysis.

Conclusions

BIB milling is an advanced sample preparation technique capable of managing highly complex and sensitive specimens. Utilizing dynamic solutions like the ArBlade 5000 or its smaller counterpart, the IM4000II, professionals across various industries can explore the internal structure of samples, gaining insights into their true nature while eliminating defects commonly associated with conventional mechanical methods.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Europe.

For more information on this source, please visit Hitachi High-Tech Europe.