Sponsored by CARBOLITEReviewed by Emily MageeMay 26 2025

Heat treatment of advanced materials, particularly those used in high-performance supercar components, demands precise control over temperature, atmosphere, and process timing. The Carbolite HTCRMA 6/220 high-temperature clean room oven with modified atmosphere capability exemplifies the technical innovation required for such applications.

This article details the technical aspects and performance of the HTCRMA 6/220 in the controlled curing of supercar components.

Image Credit: i viewfinder/Shutterstock.com

Technical Requirements and Design Solution

In this case, the customer’s process called for rapid heating and cooling, stringent temperature uniformity, and extremely low oxygen levels to prevent oxidation or combustion of specialty coatings applied to the components.

The workflow involves coating supercar parts, allowing natural drying for solvent evaporation, and then heat treating under a nitrogen atmosphere to prevent oxygen-induced degradation.

To support a fast heat-up rate, the Carbolite HTCRMA 6/220 is equipped with enough power to raise the internal temperature to 420 °C within 2 hours, even with a 20 kg load in the chamber. Upon reaching setpoint, a dwell period ensures thermal equilibrium and uniform heat treatment throughout all components.

HTCRMA 6/200 600 °C oven, 200 liter capacity. Image Credit: CARBOLITE

Atmosphere Control and Gas Management

Atmosphere purity is key to this process. The oven is fitted with a sophisticated gas delivery system capable of two distinct nitrogen flow rates: a high rate for initial purging to displace oxygen, and a lower rate during processing to maintain low oxygen levels and minimize nitrogen consumption.

Gas flow is regulated automatically by the temperature controller, which operates solenoid valves in response to program segments. The system also integrates a door interlock that cuts off nitrogen flow when the door is opened, enhancing operator safety by preventing accidental asphyxiation.

Pressure management is addressed through a relief valve, which protects against any potential build-up of nitrogen or residual volatile vapours during processing. An automatic butterfly valve in the exhaust duct ensures that airflow is only present during active cooling, preserving atmosphere integrity during heating and dwell periods.

Independent oxygen meter. Image Credit: CARBOLITE

Rapid Cooling Technology

The HTCRMA 6/220’s fast-cooling feature enables the chamber to cool from 420 °C to 80 °C within 80 minutes when empty, whilst maintaining the integrity of the atmosphere. This is achieved by two high-capacity fans that circulate air around the outside of the chamber through dedicated ducts, efficiently extracting heat from the system.

With a full 20 kg load, cooling rates vary depending on the material’s thermal properties, but the system’s design ensures consistently high performance.

Top of the oven showing the cooling duct, outlet valve & access port. Image Credit: CARBOLITE

Performance Validation: Oxygen Level and Temperature Uniformity

The oven’s ability to maintain an inert atmosphere is critical for this application. While typical air contains 21 % oxygen (210,000 ppm), the HTCRMA routinely achieves oxygen levels below 50 ppm; in this specific deployment, levels as low as 7 ppm were independently verified by the customer when operating at a nitrogen flow of 20 liters per minute.

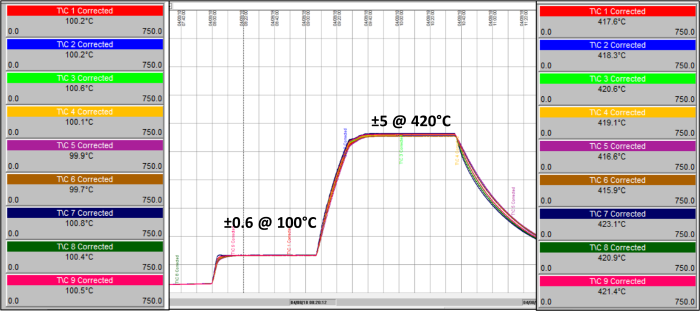

Temperature uniformity is equally impressive. At 100 °C, the oven achieves a uniformity of ±0.6 °C with an offset of +0.3 °C, and at 420 °C, uniformity is maintained within ±5 °C. This level of control ensures all components are treated equally, a requirement for high-reliability automotive applications.

Temperature uniformity chart. Image Credit: CARBOLITE

Process Data Snapshot

Source: CARBOLITE

| Time |

Temperature (°C) |

Oxygen Level (ppm) |

| 09:15 |

92 |

14 |

| 09:19 |

175 |

8 |

| 09:21 |

212 |

8 |

| 09:25 |

282 |

7 |

| 09:29 |

331 |

7 |

| 09:34 |

343 |

7 |

| 09:38 |

348 |

8 |

| 10:07 |

172 |

8 |

Temperature ramping, steady dwell, and fast cooling are clearly visualized in the accompanying charts—key indicators of process efficiency and consistency in high-throughput production settings.

Conclusion

The Carbolite HTCRMA 6/220 demonstrates advanced capabilities in precise thermal processing and atmosphere control for the automotive industry’s most demanding applications. Its combination of rapid thermal cycling, superior temperature uniformity, and ultra-low oxygen environment makes it an ideal solution for the heat treatment of supercar components, supporting the production of materials that meet the highest standards of performance and reliability.

For materials science professionals looking for dependable, flexible, and reliable heat treatment equipment, Carbolite’s HTCRMA range sets a new benchmark for technical excellence.

This information has been sourced, reviewed and adapted from materials provided by CARBOLITE.

For more information on this source, please visit CARBOLITE.