AzoMaterials speaks to Cassandra Phillips and Qichi Hu from Bruker about how their new Resonance-Enhanced Force Volume AFM-IR technology overcomes the limitations of conventional nanoscale characterization by combining chemical specificity with sub-10-nanometer spatial resolution, even for delicate or loosely bound samples.

What fundamental problem does AFM-IR solve in nanoscale characterization?

AFM-IR offers a range of advantages over nanoscale or Briggs spectroscopy. AFM-IR corrects a fundamental issue with AFM, where we have access to powerful nanoscale topography, mechanical, and electrical imaging, but no direct way of validating the material's chemistry underneath the AFM probe.

We can perform related measurements, such as examining how the modulus might relate to the material composition underneath the probe, but these are all indirect measurements rather than looking at the actual chemical signatures of the material.

Infrared spectroscopy or spectromicroscopy, on the other hand, gives us access to very rich chemical bonding information on the sample’s surface. We can see exactly what materials are present in a sample when collecting an infrared spectrum on it, but we are restricted to several micron pixel sizes by the diffraction limit (half of the wavelength, typically about 5 to 20 microns or 2 to 10 microns of lateral resolution).

AFM-IR lets us circumvent these limitations and combine the best of both worlds. We can perform spectroscopy, keeping the AFM probe fixed in space and sweeping an infrared light source over the potential range to measure chemical signatures on the nanoscale with sub-10-nanometer lateral resolution.

We can also perform imaging, keeping the infrared laser wavelength fixed and rastering the probe over the surface to examine chemical moieties on the surface with very high, wavelength-independent resolution.

Both techniques can be performed while retaining the same rich chemical information.

A number of techniques can perform nanoscale infrared spectroscopy, but AFM-IR is unique in terms of its simplicity and well-understood physics.

We can describe how AFM-IR works: an infrared pulse arrives at the sample surface. If the sample absorbs at that wavelength, it takes in that energy, undergoing a rapid relaxation and a thermal expansion that provides a mechanical impulse onto the AFM probe.

The magnitude of this force is directly proportional to the absorption coefficient, which is what we would measure using FTIR.

The AFM-IR measurement is closely correlated with FTIR, but only when the sample is mechanically coupled to an AFM probe. This provides very high lateral resolution on the order of a probe radius. This is also important because AFMs are already excellent at detecting.

Watch the full webinar

What makes Resonance Enhanced Force Volume AFM-IR a significant step forward?

Bruker has been developing this technology for a very long time. In 2010, it introduced the first generation of nano IR products, and in 2021, it innovated the IconIR, the bestselling AFM that offers the highest-performance IR capabilities.

This long history has enabled innovations, culminating in 2024 with the release of the new REFV AFM-IR mode.

We can characterize existing AFM-IR modes in several different ways, for example, by their base mode of operation, the sensitivity of the mode, the mode’s spatial resolution, whether the mode avoids lateral forces, the method of cantilever excitation, and any additional parameters that we can measure.

Each of the three available modes has a range of advantages and limitations, meaning selecting the correct mode for the application in question is essential to collect excellent data.

We wanted to expand this further, adding capabilities and offering new insights into material samples.

REFV AFM-IR is built upon the main principles of resonance-enhanced AFM-IR, which involves a direct excitation of the AFM cantilever while probing the sample surface.

However, using a force volume or data cube operation method avoids the limitations of operating in contact mode, reducing the lateral forces and moving pixel to pixel rather than directly scanning the sample surface.

PS-b-PMMA core shell with accompanying IR spectrum. Scan size (X) 240 nm. Image Credit: Bruker Nano Surfaces and Metrology

Can you describe how REFV AFM-IR achieves simultaneous spectroscopy and mechanical mapping?

The AFM probe touches the surface to acquire a force curve, holding at a set force for a set period of time, while the infrared measurement is validated before retracting and withdrawing to measure adhesion or other mechanical properties. The probe then moves onto the next pixel and repeats the process.

We work in the same two ways as previously: quickly imaging each pixel to collect images in as little as three minutes, or holding for a longer period of time and sweeping an infrared laser source to acquire spectra at these individual points in space.

Again, this approach simultaneously collects data on various mechanical properties. It is also possible to track the cantilever's mechanical phase to reduce distortions caused by mechanical artifacts.

How does REFV AFM-IR mode improve performance when working with soft or loosely bound samples?

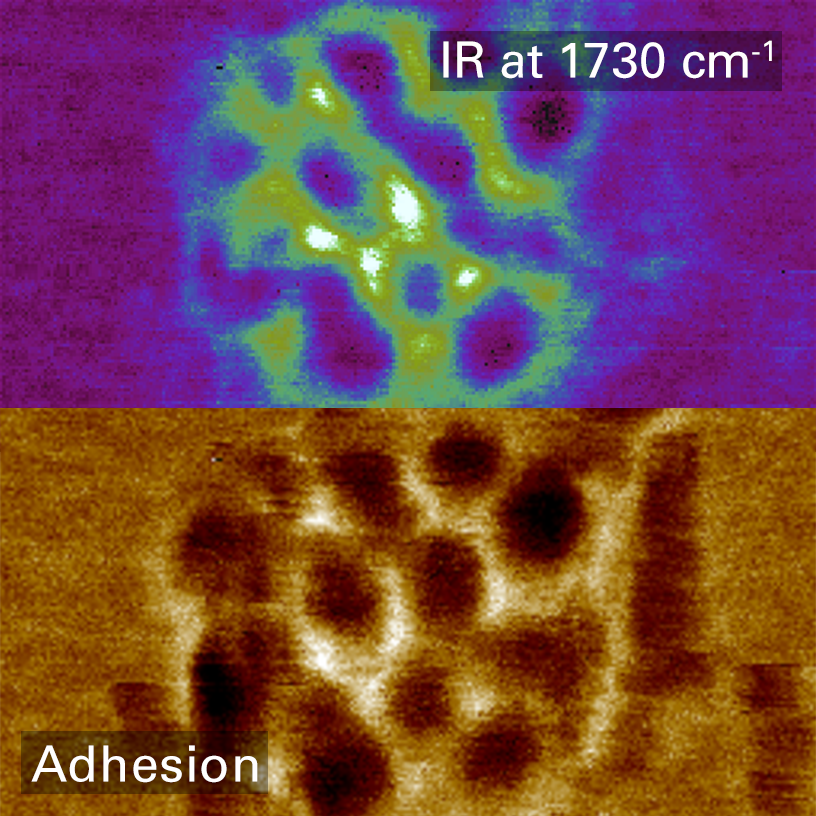

REFV AFM-IR mode avoids lateral forces using pixel-by-pixel probing, enabling stable imaging of delicate materials like block copolymer agglomerates.

For example, we analyzed a PSB PMMA core shell sample- a small agglomerate of block copolymer PS and PMMA about 200 nanometers wide and 5-10 nanometers high. This material often forms into small spheres that can aggregate together.

Attempting to image this sample using traditional resonance-enhanced AFM-IR would be impossible because it is too loosely bound to the surface. The probe would end up moving the sample around.

However, using REFV AFM-IR allowed us to view the sample’s chemical contrast.

REFV AFM-IR’s high lateral resolution is equivalent to tapping mode, which is sub-10 nanometers. At the step edge, we could read 6.5 nanometers of lateral resolution with resonance and hand force volume. We could also read the sample’s mechanical properties from the force curve.

It was also possible to simultaneously observe the adhesion channel and the modulus channel while performing this measurement.

We use force volume operation with resonance-enhanced mode to offer the same sub-nanometer spatial resolution as traditional methods while avoiding lateral forces. This is ideal for working with soft samples.

Another example involved looking at a sensitive monolayer sample in purple membrane- a monolayer protein film on a gold substrate.

A spectrum taken of the purple membrane showed a nice relationship in the amide-1 and amide-2 bands, an important element of standard protein characterization. We completed additional measurements, looking at the protein’s secondary structure and seeing how this protein is assembled on the substrate’s surface.

We then looked at the REFV AFM-IR’s mapping capabilities. The adhesion channel shows the ITER absorption, the main signal corresponds to the purple membrane, and areas off of the purple membrane show increased signal and increased or decreased adhesion.

These variations likely correspond to some surface contamination effects from the production of the purple membrane sample.

This technique can also be used with a PSV PMMA block of polymer film, a film of the same material as the core-shell sample I already mentioned. In this case, we saw the same excellent lateral resolution here, 7.5 nanometers.

It was also possible to examine adhesion, chemistry, and topography simultaneously. In this instance, we did not see much variation in either the topography or the adhesion channel, but some features were observed that corresponded with the phase separation of the polymer blocks.

However, the sample’s chemistry showed stark contrast with clear phase separation between the polystyrene and PMMA domains. This separation was more visible than it would have been using other techniques, perfectly validating the phase separation in this measurement.

One potential issue when performing these measurements is that, as we scan over the surface, because we are exciting the resonance mode of the cantilever, the resonance can shift as we move from hard areas to soft areas or change the contact area between the probe and the sample surface.

For example, measuring a relatively stiff area versus a relatively soft area can lead to a shift in the resonance peak of the IR measurement. This can create mechanical artifacts in the measurement, because measuring at a fixed frequency can result in an artificial decrease in the detected signal that corresponds to the shift in the resonance frequency.

It is essential to measure the true signal as it exists on the sample surface. To do this, we must track the resonance frequency as it shifts over the material. This is done using Bruker’s phase lock loop technology, which is made possible thanks to our knowledge of contact resonance and tapping mode.

These measurements are also possible without any lateral forces. REV AFM-IR measurements result in minimal tip degradation, even if the measurement was left running overnight or for multiple days.

Because contact mode involves much higher lateral forces, as soon as we start scanning the surface, we can see a double tip artifact corresponding to wear of the cantilever coating.

How does the system distinguish between materials like polystyrene and LDPE during imaging?

Polystyrene shows a strong 1493 cm?¹ IR signal, while LDPE shows weak or distinct peaks, enabling material contrast.

For example, we performed simultaneous measurements of the mechanics of a PSLDPE sample, seeing a film of polystyrene with low-density polyethylene inclusions over the sample area.

This is a commonly used sample for verifying mechanical differences in a material. Using a 40-newton-meter TNR-D probe, we saw that the modulus and the adhesion channels strongly correlated to the expected moduli of the material.

We added a step to assess the sample’s chemistry, tuning to 1493 wavenumbers, corresponding to an aromatic polystyrene mode. This showed that the film is polystyrene with excellent phase separation between PS and LDPE. Tuning to 1472 showed the overall signal response from the low-density polyethylene, revealing those inclusions.

This sample shows a direct relationship between the modulus parameters being measured and the material’s chemistry, as evidenced in the relationship between PS and LDPE.

What advantages does real-time resonance frequency sweeping provide?

The single resonance sweep capability allows us to go further in our sample analysis. We can set our start and end frequencies and sweep through the available range rather than keeping the laser pulse rate fixed or modulated by a phase lock loop.

This allows us to measure the exact resonance frequency of the cantilever and the exact amplitude corresponding to this. Focusing on the PSB PMMA core shell sample, a much richer data cube can be collected through this frequency sweep, and it is now possible to directly measure the changing intensity and drive frequency position for the first time thanks to REFV AFM-IR.

This also provides us with more detailed insight into the material, and the ability to simultaneously validate the shifting contact resonance frequency and the IR intensity with the mechanics.

Can you walk us through the basic workflow of a REFV AFM-IR scan on the Dimension IconIR system?

Resonance Enhanced Force Volume AFM-IR is a new method that effortlessly delivers artifact-free multiplex data sets. These capabilities are only available on Bruker’s signature Dimension IconIR and IconIR300 platforms.

These systems simultaneously collect topography, IR, modulus, and adhesion data in under six minutes. A typical workflow begins with an IR imaging scan. This typically involves setting a series of SM and IR parameters before beginning the scan.

This scan reveals the sample’s topography, allowing us to investigate its features further. The modulus and adhesion channel of the material are also measured simultaneously - a key benefit of this new mode.

The IR signal is collected pixel by pixel to create the image, and once this has been captured, it is moved to a new tab in the software called the Spectral View. Users can select a few points in this view to perform IR spectroscopy measurements. This process is highly repeatable and there is no need to smooth raw data, meaning that it consistently yields high-quality spectroscopy data.

The resonance frequency sweep is completed next. It is first necessary to confirm the imaging area before changing a few parameters in the settings. Essentially, rather than working with a fixed resonance, we sweep the resonance, slightly increasing each pixel's time constant. It is also important to turn off the PLL feature, because we will sweep the frequency.

Once the scan is started, we can monitor the time and the signal via the instrument’s display.

Changing the power percentage during the scan is often necessary to maintain a good signal level.

For example, once we have acquired an image, we can move the cursor around it to see how the IR signal contrast differs depending on its position and resonance. The modulus and adhesion channels remain similar to the regular scan, but altering the resonance allows us to see the best contrast in terms of the IR signal.

Next, we would perform a real-time feeding of the resonance by setting a few parameters. The key benefit of this live feeding is that we can find the exact resonance frequency and the Q factor of the resonance.

Changing to any channel to display the fitted result reveals the resonance and the fitting curve. This approach also finds the peak frequency, peak width, and Q factor of the resonance for each pixel.

What insights can be gained from offline analysis after a scan is complete?

Offline tools allow us to perform pixel-by-pixel comparison, baseline correction, and spectrum normalization to highlight material differences.

Once we have acquired an image, we can select any channel, for example, the IR channel or the modulus channel, for further analysis.

For example, we could select four pixels of an image from the PSLDPE image from earlier, two featuring polystyrene and two featuring LDPE. We could view the IR signal during the force curve cycle for each pixel, examining signal level for each.

When working with spectroscopy data, we can also perform baseline correction and normalization, allowing us to see very distinct spectra between the two materials. For example, polystyrene has a very strong 1493 peak wave number peak, while LDPE has no absorption at this wave number. In contrast, LDPE would exhibit a strong signal at a 1460 wave number.

This type of offline analysis provides us with more information, allowing us to perform further analysis pixel by pixel for whatever channel we select.

Watch the full webinar

About the Speakers

Qichi is currently a Senior Staff Applications Scientist at Bruker Nano Surfaces and Metrology. He received a bachelor’s degree from Peking University and Ph.D. from University of British Columbia. He then did postdocs in U.S. university and national labs. Qichi has been working on nanoIR development and applications for over a decade at Anasys and now at Bruker.

Cassandra did her Ph.D. at the University of Toronto exploring the photophysics of boron nitride nanotubes using scattering scanning nearfield optical microscopy (s-SNOM) and computational models. She has been working at Bruker Nano Surfaces and Metrology since September 2019 as first an Applications Scientist and now as a Senior Product Manager, focusing on nanoscale IR spectro-microscopy and other correlated imaging techniques realized with atomic force microscopy.

This information has been sourced, reviewed and adapted from materials provided by Bruker Nano Surfaces and Metrology.

For more information on this source, please visit Bruker Nano Surfaces and Metrology.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.